SGS, an inspection, verification, testing and certification company based in India, announced that it has enhanced its material testing capabilities with the introduction of solar simulation testing at its automotive testing laboratory in Manesar, India.

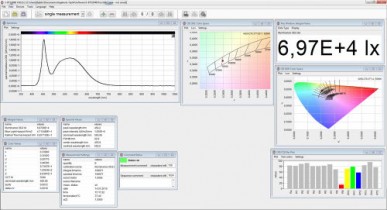

Solar radiation causes numerous unwanted effects on materials exposed for extended periods. These changes range from aesthetics (like fading colors) to structural changes (increase in brittleness and the loss of various strengths). Solar simulation testing is used to simulate the spectra of natural sunlight to help determine how a material will react when exposed to sunlight over a period of time.

The Solar simulation testing setup comprises of two chambers fitted with metal halide lamps which can generate irradiance up to 1200 W/m2, therefore capable of complying with almost all of the automotive industry's testing requirements. The chambers can be used to perform solar simulation tests at various temperatures and humidity conditions, in line with global testing requirements. Multiple chambers with different capacity have been put in place to cater to different specifications that are often required for interior and exterior components.

This addition enables SGS to deliver a full range of automotive testing services in India. Its three automotive testing laboratories in Chennai, Manesar and Pune, equipped with the latest technology and equipment, offer the necessary expertise and capabilities to perform tests for metal and polymer materials, dynamics, airbag deployment, corrosion, environmental simulations, vibrations, on-board electronics, VOCs, ELVs and substance of concern.

Back to News

Back to News