When thinking about solar module optimization, most of the attention goes to solar cells and other visible components; however, underestimating the importance of hidden parts comes at a price. Backsheets are one of those hidden parts, and backsheet failure affects performance of a photovoltaic installations, which reduces the return on investment.

A solar module’s estimated useful life ranges from 20 to 30 years. However, field data and experience tell us that some backsheets are failing decades earlier than they should. On the one side, it is common knowledge that factors such as varying climatic conditions and mechanical stress significantly impact lifetime predictions. On the other, the use of low-quality materials is having the biggest impact. In all climates and in all types of modules, reduced power output and premature degradation can be, to a great extent, attributed to a faulty backsheet. This year’s DuPont (3GW) analysis for instance (from DuPont 2020 Global PV Reliability Report), which supports previous research on the topic, indicates that 16% of all modules inspected suffered some degree of backsheet failure. In other words, if the 1.1GW of the forecasted 112GW PV capacity installed in 2020 (DuPont 2020 Global PV Reliability Report) was to register some degree of backsheet failure, it could result in $500m of maintenance costs (based on a CPN $4.8 USD/kWp from Solar Power Europe, “Global Market Outlook” 2020).

The situation gets even more complicated if we consider that most PV projects assume a very low module failure rate, at or below 0.05% per year. In fact, this is only true in modules built with high quality materials. Unproven and untested backsheets effectively put at risk the financial viability of a project.

Why are traditional backsheets failing?

In recent years, the demand for low-priced modules has put an increasing cost-pressure on manufacturers and has ultimately led to the incorporation of lower-cost materials, posing a risk to module lifespan and performance.

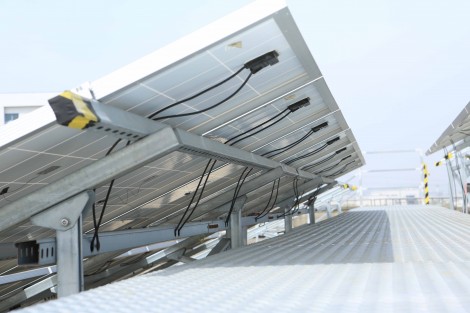

The rearmost layer in a solar module, the solar backsheet is a three-layer laminate that provides insulation and protection. Considered to be the first line of defense against air and moisture, which can corrode electrical components, backsheets too have been the victim of the extreme price pressure in the solar industry, meaning traditional backsheets now seem to be unable to provide long-term durability.

Alongside cost-pressure, the pace of module innovations is far outstripping the pace of reliability data from the field and even from testing. Some innovations are expected to improve module reliability but have little or no data to confirm these expectations,.

Backsheet failure can be attributed to a few macro areas:

Core strength: Low-stabilized PET is the most commonly used core layer material in traditional backsheets. Although very cost-effective and able to provide good electrical insulation, the PET polymer is also sensitive to moisture and sunlight. To increase its resistance, thin and durable outer layers of fluoropolymers like PVF, PVDF or highly stabilized PET are added as outer layers. This solution has been proven effective in the short term, however as soon as the outer layers get damaged or delaminate, the backsheet degrades rapidly.

Reduced core protection: Not only is the core extremely weak, but the protective fluoropolymer outer film meant to protect the module has halved in thickness and is now less than 20 microns for most fluoro-based backsheets on the market today. In some cases, it is almost a few microns thicker than a polymer coating. In some cases, the outer “protective” layer is as little as 10 microns, making the backsheet prone to bigger and faster damage.

Price-focused production: To further bring production costs down, parts included in the Bill of Materials (BOM) are commonly exchanged for cheaper options. In the case of base films for example, they are often sourced from multiple suppliers and laminated with various adhesives. Not only does the use of inferior, untraceable, and uncertified materials and adhesives in the lamination process lead to an inferior backsheet that is more likely to fail, it also makes it extremely difficult to identify the ultimate cause of failure.

Short-term savings vs long-term value

Cheaper PV modules are a costly choice in the long run, as the constant need for replacement options leads to unplanned downtime and maintenance costs. Quality backsheets can avoid poor power output or outright module replacement and can help extend the useful life of solar projects.

When choosing the backsheet, it is important to obtain the test data, including the elongation-to-break after damp heat and extended-duration testing using a backsheet test sequence. Asking clarifications on the module manufacturer warranty, as to what is considered repairable, is the obvious next step. We have seen instances of manufacturers performing infield repairs by ‘wallpapering’ another backsheet on top of the failed backsheet. It goes without saying that there can be no guarantee of long-term performance when that happens.

In summary, backsheet damages can be avoided. Backsheets have only started massively failing when the prices of solar modules plummeted, and innovations in solar cells were prioritized above backsheet innovations, for which the cheaper quick fix was chosen.

Backsheet failure can be avoided

To tackle the challenge of backsheet failure, performance-focused manufacturers, such as DSM, have been working to provide the industry with reliable backsheets. In DSM’s Endurance backsheets, co-extrusion has been used to replace traditional lamination. Chaturvedi explained that It is a single-step process that requires no adhesives, resulting in strongly coherent multi-material products with a strong polyolefin core that’s moisture-resistant.

Written by Vivek Chaturvedi, Business Leader Endurance Backsheets, DSM Advanced Solar, and Henry Hieslmair, Principal Engineer, Solar Technology Group DNV-GL

Back to Features

Back to Features