From electric bikes and scooters to hybrid and electric cars, transportation is undergoing a major overhaul. As the demand for more efficient options rises, the automotive industry is continually seeking new ways to evolve their energy efficient offerings. Though solar power is commonly associated with energy savings on homes and buildings, the integration of solar cells into vehicles is becoming a viable option as tandem technology evolves. Tandem technology would enable solar power to be integrated into the roof or other parts of a vehicle to preserve primary battery power used by car electronics or air conditioning. As an additional benefit, a highly efficient solar roof would extend the electric range of a vehicle substantially.

The main barrier so far in integrating solar into cars is the limited surface area available on the car to accommodate solar panels. To address this issue, efficiency of the solar panel must be maximized—an issue that tandem technology addresses. Tandem cells are solar cells made by stacking two or more cells on top of each other to reach a higher power conversion efficiency (PCE) than what’s possible using separate technologies. Since solar cells with wider-band gap photo absorbers generate higher voltages, thermalization losses are significantly reduced in tandem solar cells, compared with single junction solar cells that absorb the same number of photons. This results in a higher PCE for tandem solar cells.

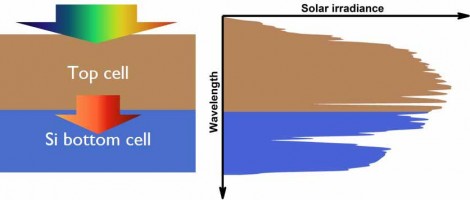

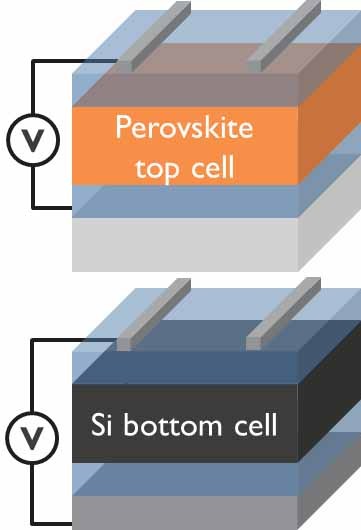

An obvious requirement is that the material of the top cell is transparent to the light that it doesn’t convert. An additional boost is given if the materials in the stack are sensitive to a distinct part of the light spectrum, so that they don’t scavenge on each other’s conversion potential. The material that captures the shortest wavelengths (e.g., blue and green) will then be on top, while the bottom material converts the longer wavelengths (e.g. red and near-infrared), as depicted in Fig. 1.

Fig. 1: Schematic of a tandem solar cell comprising two solar cells with descending bandgap energies. Incident photons with energies above the bandgap of the top solar cell are harvested at a higher voltage by the wider-bandgap top solar cell. The lower-energy (longer-wavelength) photons transmitted by the top solar cell are harvested by the bottom solar cell.

Tandem solar cells have already been widely used for space applications. Such tandem solar cells comprise up to five subcells based on III-V semiconductors, and exhibit PCEs of up to 38.8% under 1 Sun illumination. However, these tandem solar cells have a high degree of complexity and are expensive to manufacture on a large scale. As a result, the use of III-V based tandem solar cells has so far been restricted to niche applications like powering spacecrafts.

For terrestrial applications, manufacturing costs profoundly influence the extent of deployment. Since the terrestrial PV market is dominated by c-Si solar cells, adding a low-cost absorber on top of the c-Si, resulting in high-efficiency tandem solar cells, will be a more promising route to lowering the levelized cost of electricity (LCOE). Until a few years ago, there was a lack of efficient, low-cost solar cells that could be used in a tandem configuration with the PV technologies established in the market. However, the advent of perovskite solar cells and their rapid progress has changed the status quo.

Perovskite, a mineral containing calcium titanate (CaTiO3), was discovered in 1839 and named after the Russian mineralogist Lev Perovski. Today, the term perovskite is used to denote all the compounds that have a crystal structure similar to CaTiO3. The generic chemical formula of perovskites is ABX3, where A and B are positively charged ions of different sizes and X is a negatively charged ion. Depending on the choices of A, B and X ions, perovskites can be insulators, semiconductors, conductors or superconductors. Perovskites used in solar cells are crystalline semiconductors and are called hybrid metal halide perovskites. In such perovskites, the A site is usually occupied by monovalent methylammonium CH3NH3+ (MA) or formamidinium CH(NH2)2+ (FA) or caesium (Cs+), or a combination of these. The B site is taken up by bivalent lead (Pb2+) or tin (Sn2+), or a mixture of both. The X site is reserved for halides, such as iodide (I–), bromide (Br–) or chloride (Cl–), or a mixture of these.

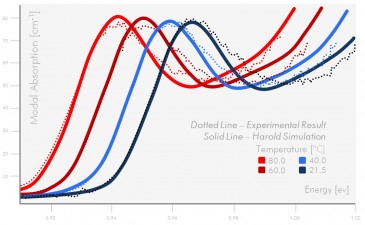

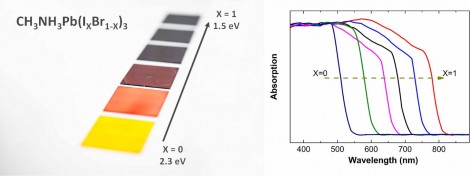

An interesting property of perovskites, particularly attractive from a tandem perspective, is the ease of bandgap tuneability. The bandgap of most perovskites can be tuned simply by varying their chemical composition, most commonly the anion; the replacement of ions alters the size of the perovskite crystal lattice, thus changing the bandgap. This interesting property enables the fabrication of perovskites with bandgaps ranging from 1.1eV to 3.2eV, as demonstrated in Fig. 2. The most commonly used perovskites for high efficiency solar cells have a bandgap of ~1.6eV. For tandem applications with c-Si and copper indium gallium selenide (CIGS), perovskite bandgaps between 1.7eV and 1.8eV are of particular interest.

Fig. 2: Variation of the composition, here the iodide/bromide halide ratio, results in changing the width of the bandgap and thus the absorption edge and colour of the perovskite film

While for single junction perovskite cells power conversion efficiency (PCE) over 25% has been reported in last few years, recently a tandem result with a perovskite cell on top of silicon bottom cell with 29.15% efficiency was shown here. This confirms the high potential for such tandem technology to substantially surpass the efficiency limitations of single junction PV cells. Though, this result was obtained still using lab processes, on an area of 1 cm2 and working on a silicon cell with polished front surface. This involves cumbersome and time-consuming additional steps which are not compatible with high-throughput industrial fabrication.

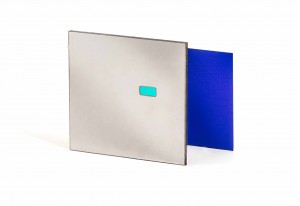

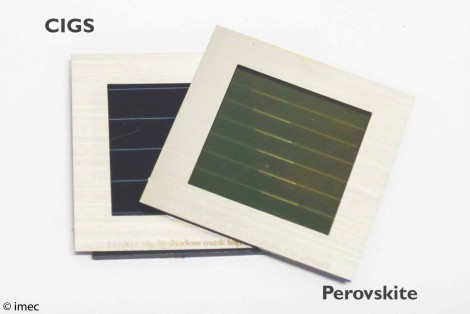

In 2018, imec reported (here) a fully scalable tandem solar module employing a methylammonium lead triiodide perovskite top solar module stacked onto an interdigitated back contacted c-Si bottom solar cell. Both devices have an identical aperture area of 4 cm² (see Fig. 3 left). With a combination of optimized transparent electrodes and efficient module design, this multi-junction solar module exhibited a power conversion efficiency of 25.3%. In later experiments, another perovskite tandem module, this time stacked on top of a CIGS module (see Fig. 3 right), was able to boost the single junction efficiency with several percentages. This work was done in collaboration with one of the world-leaders in CIGS technology, the Zentrum für Solare Energiewirtschaft (ZSW, Stuttgart, Germany).

Fig. 3: Tandems with aperture area of 4cm2 with upscaled processing for the front perovskite modules; (top) Perovskite-Si tandem; (bottom) Perovskite-CIGS tandem

These two top results not only proved the worth of perovskite as a top cell material, they also point to the fact that – because of its characteristics and flexibility – perovskite technology could be used to boost virtually any type of single-junction solar cell.

The tandem modules that imec initially designed and tested were 4-terminal modules (fig. 4, left), with the two subcells of the tandem electrically isolated and each having their own wiring. As a result, the finished product has four electrical wires coming out and therefore requires an additional convertor. In a 2-terminal module (fig. 4, right), in contrast, the two subcells are electrically connected in series and the module has only two terminal wires, a simpler configuration that is next on imec’s optimization agenda.

Fig. 4a: Schematic representation of the two main tandem architectures investigated nowadays; four-terminal (4T) configuration with electrically isolated perovskite top and Si bottom cell

Fig. 4b: Schematic representation of the two-terminal (2T) configuration whereby the top and bottom cell are electrically connected in series

With the added complexity, why choose a 4-terminal setup? Mainly because this set up maximizes performance of the two subcells. With a 4-terminal setup, it pays to use the best, optimized single-junction cells as a subcell. A 2-terminal configuration, in contrast, comes with the constraint that the series connection requires the currents to match. This may eat into some of the edge of the subcells.

Overall, the difference in efficiency between 4-terminal and 2-terminal modules is only small when measured in the lab under standardized conditions. In the field, however, with light conditions that change from minute to minute, the 4-terminal architecture has the potential for a higher yield. The downside of course is the added cost for the separate components including wiring, convertors, and junction boxes. Therefore, companies like the start-up Oxford PV have shown keen interest in the 2-terminal solution, which can be assembled into panels that can simply replace today’s panels without additional cost.

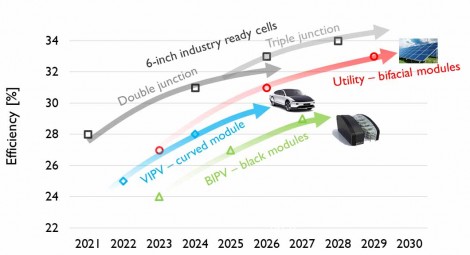

Despite the fast progress on PCE for such 2-terminal PV technologies, there are new challenges. In contrast to cSi cells, solutions for metallisation, interconnection and module lamination for tandem solar cells are still at a very early R&D stage. Since perovskite materials can’t sustain the same mechanical and thermal stress as silicon, novel materials and processes must be developed to ensure that full modules and panels can be fabricated with the tandem cells. Otherwise, market demand of this new PV technology will not rise and it will remain in the lab long term. Based on imec’s vast knowledge in module technology, with advanced metallization processes and innovative interconnection routes developed over the last few years, we’ve set out a roadmap, as depicted in Fig. 5, to bring the tandem cells and modules to technology levels that are ready for product integration. Our first target is vehicle integration, and with improved reliability and upscaled processing, the building-integrated PV market will follow. Further cost reductions in the end will also open up the possibility for tandem technology to be used in solar farms and utility scale.

Fig. 5: Our technology roadmap to realize product-ready tandem technology in the coming years, for different application areas, ranging from vehicle over building integrated PV to utility scale deployment.

Finally, tandem technology can have major importance for power-to-molecule applications like hydrogen generation. This investigation is part of the recently launched PROCURA project.

Written by Tom Aernouts, group leader of thin-film photovoltaics at imec.

Back to Features

Back to Features