Laser-cut hypotubes (LCHT) have become indispensable in modern medical technology. The delicate structures of these extremely thin metal tubes enable minimally invasive procedures such as catheter ablation, stent insertion and neurovascular procedures. However, as miniaturisation progresses, the demands on quality assurance are also increasing. Traditional inspection methods quickly reach their limits. Innovative 3D measurement technologies open up new possibilities for detecting even the smallest features while maintaining high process reliability.

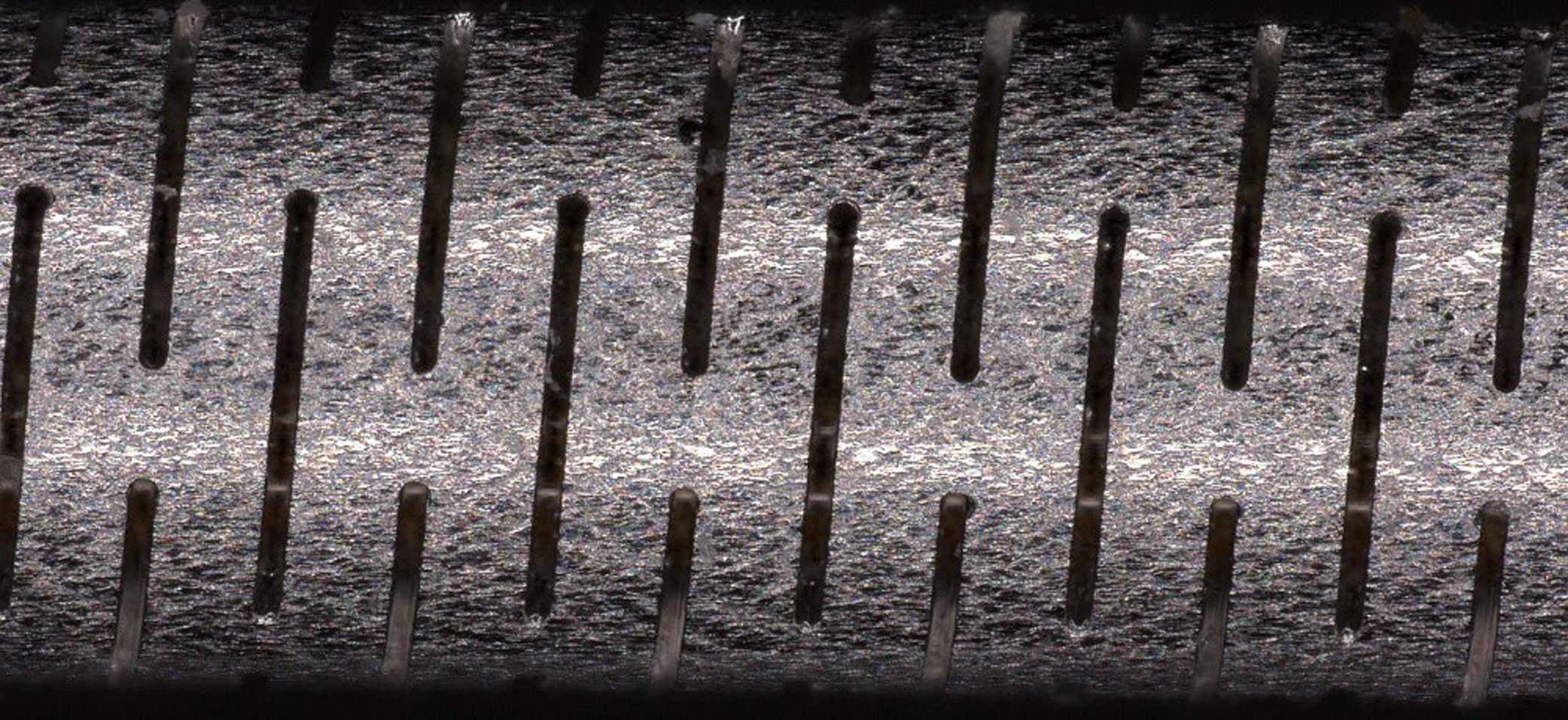

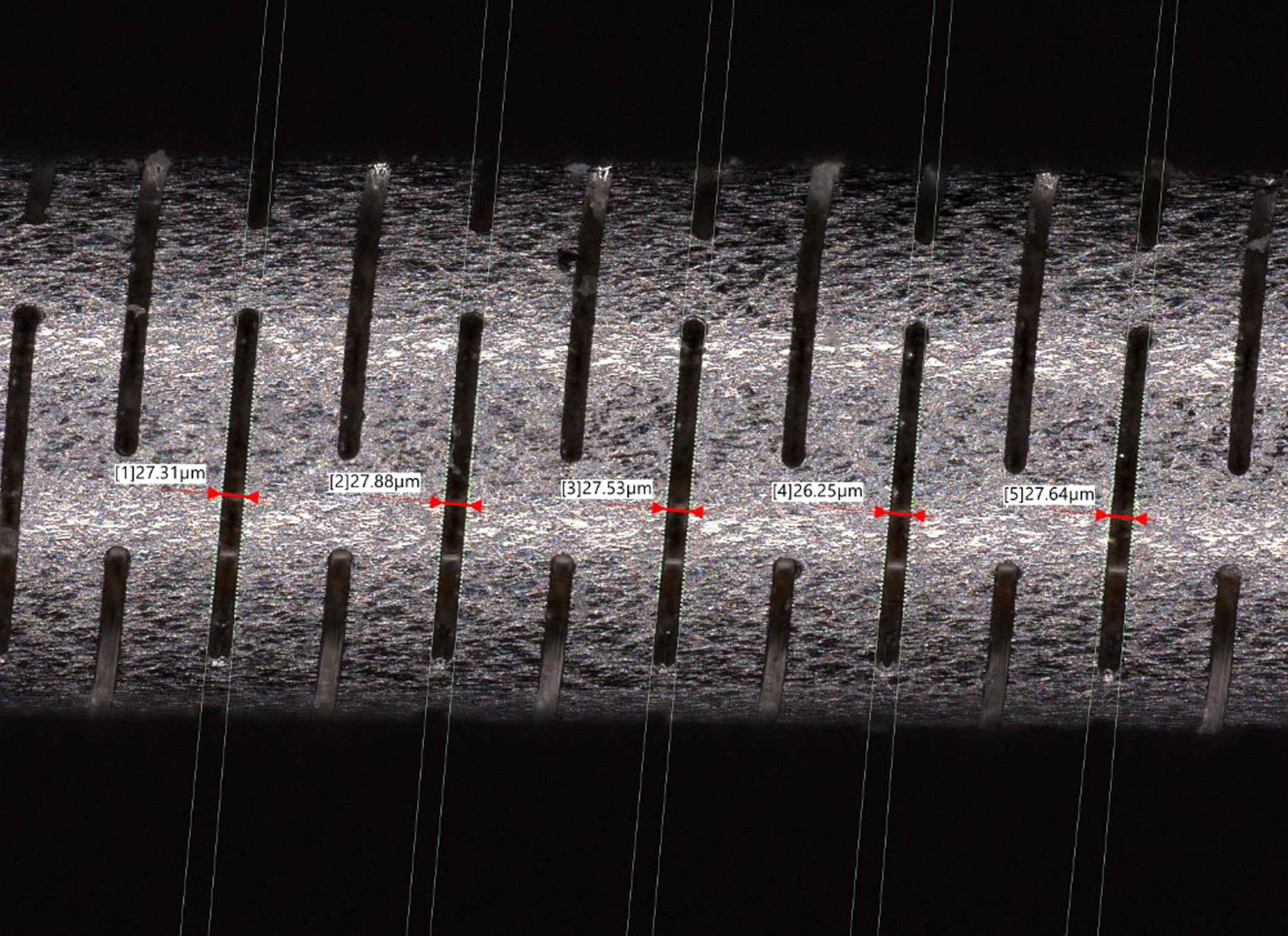

The image shows an example of a laser-cut hypotube (LCHT) being measured with a digital microscope. This image was taken at 200x magnification.

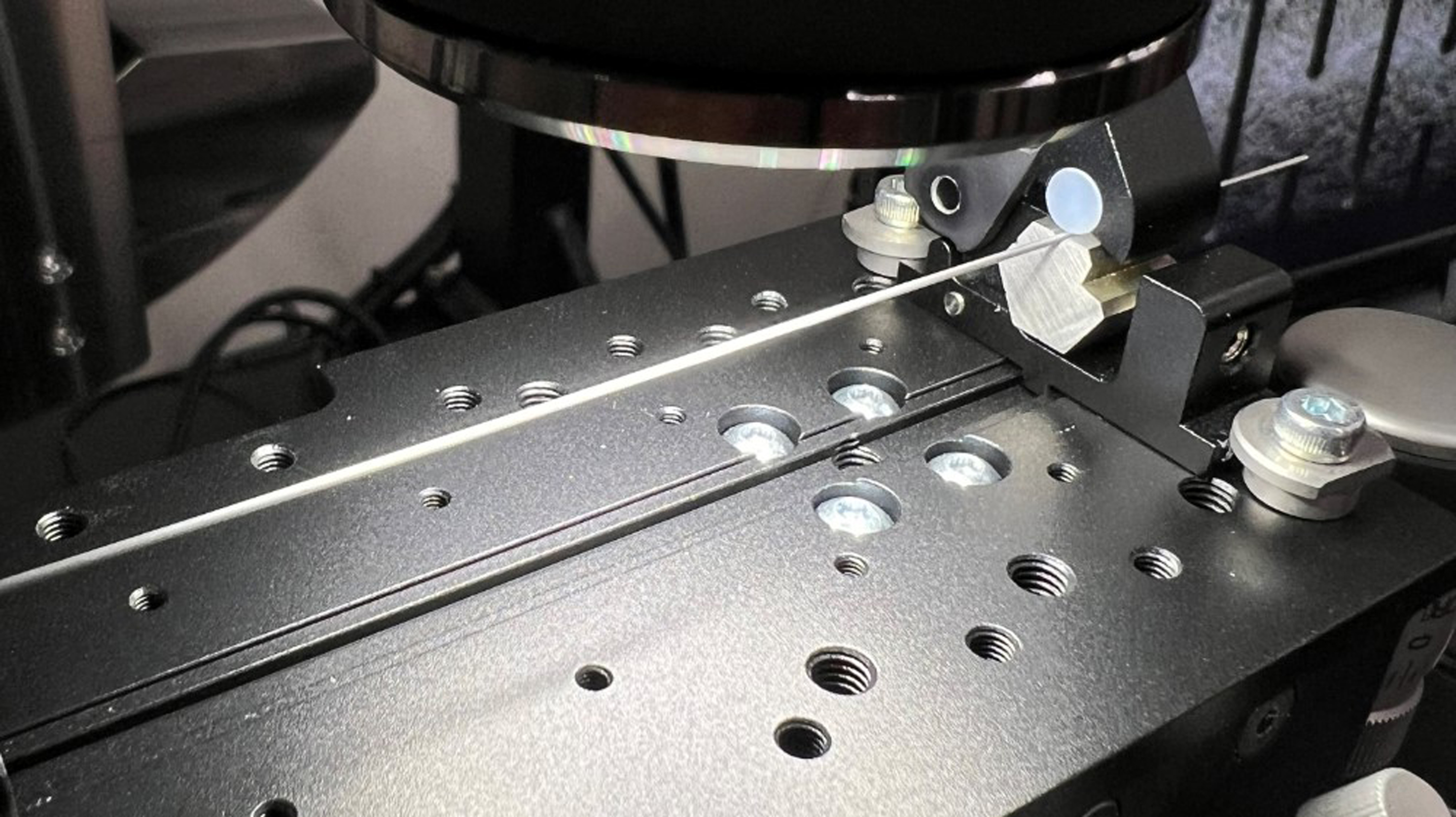

An image of the laser-cut Hypotube (LCHT) with the testing equipment used.

Why high resolution is crucial

Hypotubes have fine cuts and bores that give them their flexibility and functionality. To reliably check their geometry, the measurement resolution must be in the single-digit micrometer range, and sometimes better. A proven rule of thumb: The resolution of the inspection system used should be three to ten times smaller than the smallest feature to be measured. For example, if you want to measure a 30-micrometre feature, you need a resolution of at least 3 to 10 micrometres – this means that a data point on the part surface must be generated every 3 to 10 micrometres. This is the only way to reliably identify even the smallest deviations.

The smaller the structures, the higher the demands on the measuring system used. This is particularly true for medical applications, where absolute reliability is required. Incorrect cuts, inaccurately placed drill holes or material irregularities can have serious consequences here – both for the product and for the patient. That is why precise measurement is an integral part of every manufacturing process.

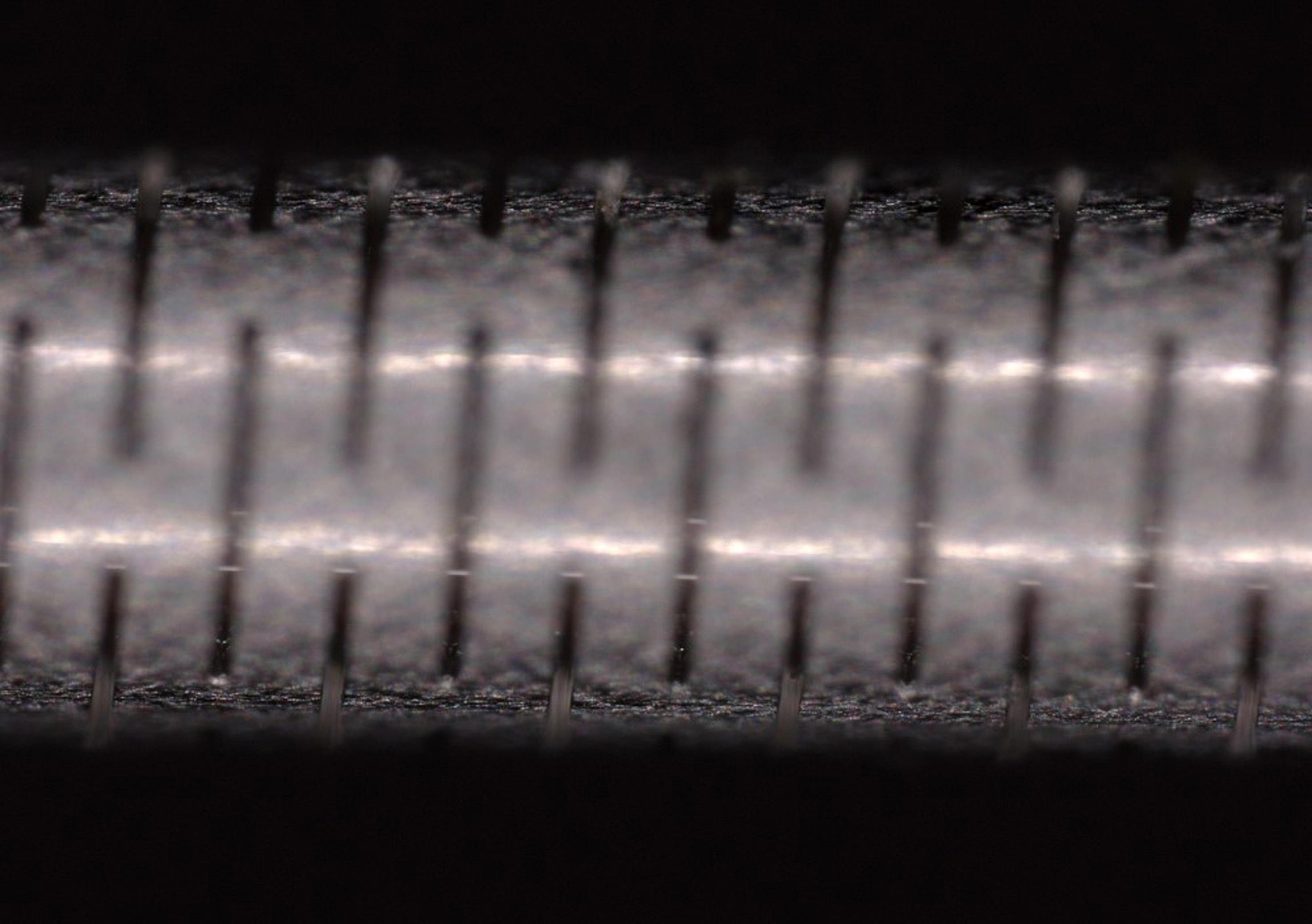

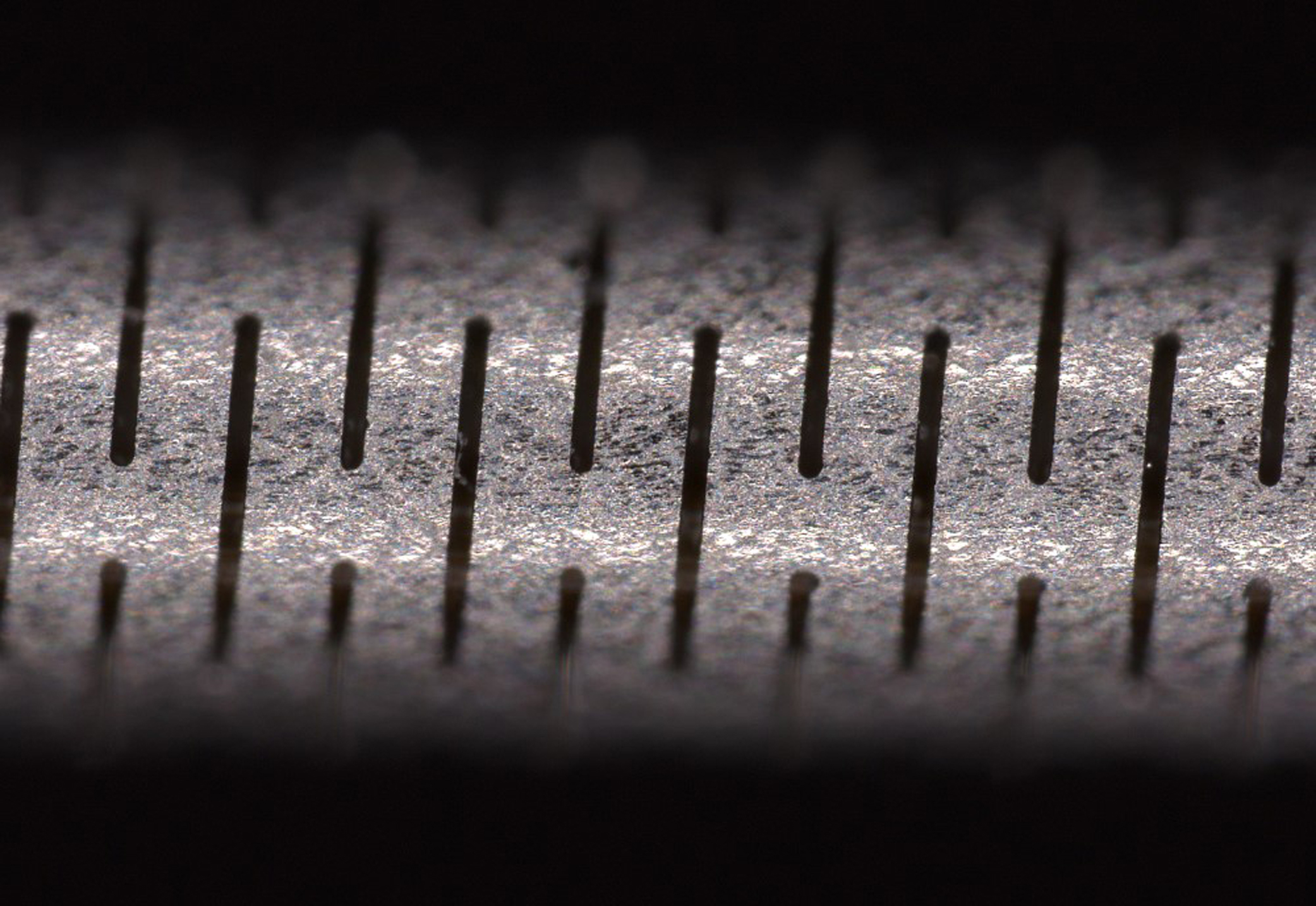

Image with simple depth of field - the focal plane lies on the lower radius of the tube.

Image with simple depth of field - the focal plane is at the upper edge of the tube.

Fully focused image of a tube, created by stacking multiple image planes. This technique enables more precise application of the measuring tools.

2D or 3D? A fundamental decision

Although 2D measurement systems are widely used and quick to deploy, they reach their limits when it comes to complex, three-dimensional structures. Especially with cylindrical hypotubes, whose curved surfaces are difficult to focus on, the choice of a 3D measuring system is usually unavoidable. It not only allows for better mapping of curved surface, but also offers a more comprehensive analysis of the spatial structure.

This is because the thin tubes are not flat workpieces, but complex, often multi-layered structures with variable wall thicknesses. Accordingly, the measurement technology must be able to adapt flexibly to the geometry and material behaviour – while delivering reproducible results. 3D measurement systems do exactly that: they not only record the X and Y coordinates, but also the height information (Z axis), thus providing a complete picture of the part surface under investigation.

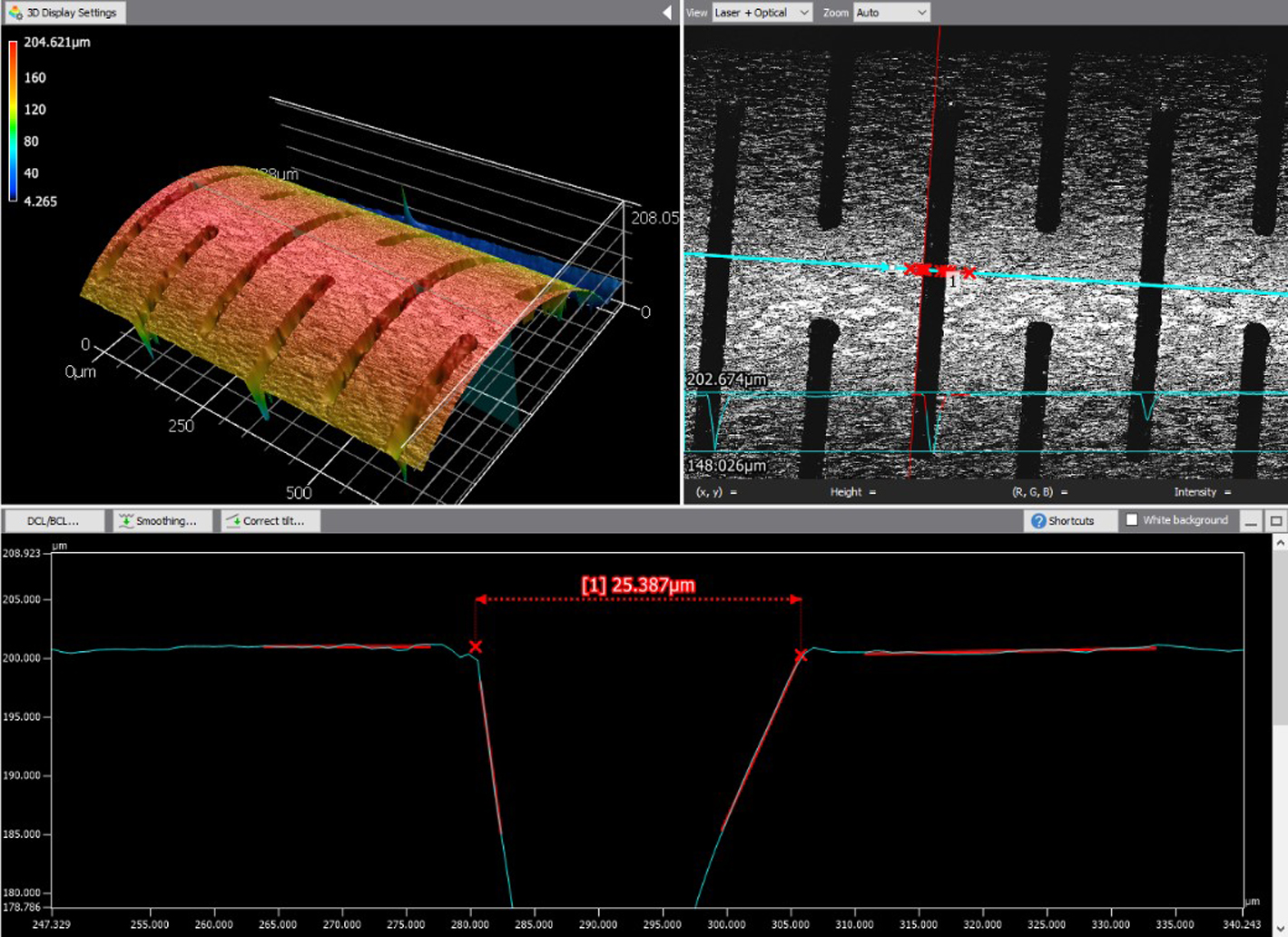

The image shows a 3D laser microscope measuring a cut in a laser-cut Hypotube. The data set generated maps a complete 3D surface.

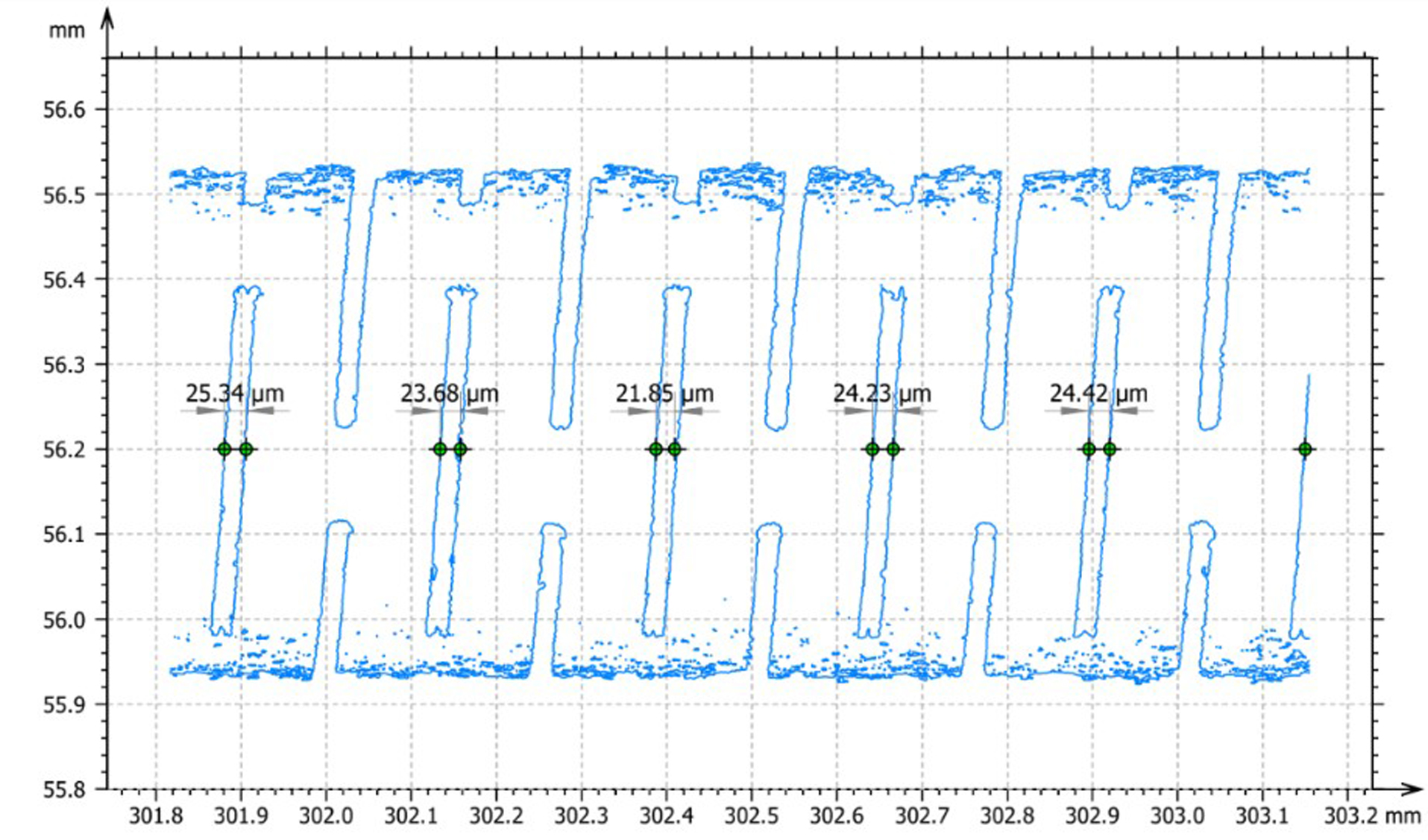

The optical 2D image shows a height profile line superimposed on a laser-cut contour. Since a complete 3D data set is available, reference lines can be defined on the inner walls of the cut contour and on the top of the tube. The intersections of these lines enable the tube width to be determined precisely.

Advantages of 3D measurement technology

3D measurement systems are particularly useful when geometries deviate from the ideal shape. Bevelled cuts or angled drill holes are often difficult to evaluate using 2D approaches, as the start and end points of the edges are not clearly defined. A 3D system, on the other hand, captures the entire topography, ensuring reproducible results.

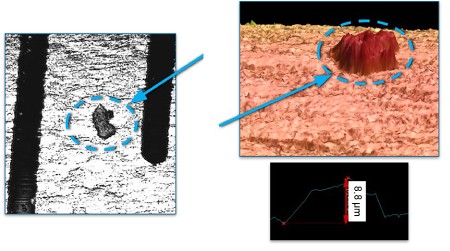

3D measurement systems also offer decisive advantages when analysing possible defects such as dents, scratches or material adhesions. Where 2D images cannot distinguish between concavities and convexities, the height information from the 3D data set provides reliable information about the type of defect. This makes defect characterisation significantly easier, faster and, above all, more objective.

Modern 3D systems can also be used to analyse functional characteristics: Are the cuts symmetrical? Do the angles of the drill holes correspond to the design specifications? Is the cut width within the permitted tolerance? All these questions can be answered with precise 3D data – either manually or automatically through software-supported evaluation.

The image on the left shows a 2D image of the pipe surface.

On the right, the 3D data allows the surface to be viewed at an angle, clearly showing that the visible defect is a protrusion. This can be measured and compared with the specifications. In this case, the determined defect height is 8.8 micrometres.

Selecting the right system

When selecting the appropriate 3D measurement system, the specific application is therefore crucial. Three technologies have proven themselves in our practice:

- Confocal microscopes deliver excellent resolution and great depth of field. They are ideal for high-precision detail images, but are relatively slow – a measurement of a few hundred micrometres along the surface can take up to 30 seconds. They are therefore only suitable for spot check measurements or small batch production runs. Their strengths lie in individual part inspection, product development and process validation.

- Digital image processing systems such as digital microscopes are significantly faster and generate 3D data by stacking multiple image planes. They are a good compromise when speed is more important than maximum height resolution. They can really show their advantages in random sampling or quality assurance, especially when large quantities need to be inspected.

- Confocal 3D scanning sensors combine high resolution with fast data acquisition. They provide raw data in the form of height profiles and enable the analysis of entire Hypotube surfaces. In combination with a high-precision motion system – such as motion control technology from Aerotech – experience has shown that highly accurate and repeatable measurements can be achieved even in automated production lines. Thanks to their modularity, such systems can be flexibly integrated into existing production environments.

The image shows a digital 3D microscope that creates depth of field by stacking images from different focal planes. It works faster than a laser microscope but does not offer the same range of functions: for example, it lacks the precise height information that would be required for certain measurements, such as determining surface roughness.

A concrete example illustrates the performance of such systems: In one application, confocal technology was used to measure five cut widths along a hypotube. This point measurement could be easily extended to the entire length of the tube – and provided reproducible results at all times. The software used also enabled automatic classification of defects and geometric deviations – a real added value for process and quality control.

Individual data set from a 3D measurement sensor with 1 µm resolution. The measurements of the cutting width at five defined positions are visible.

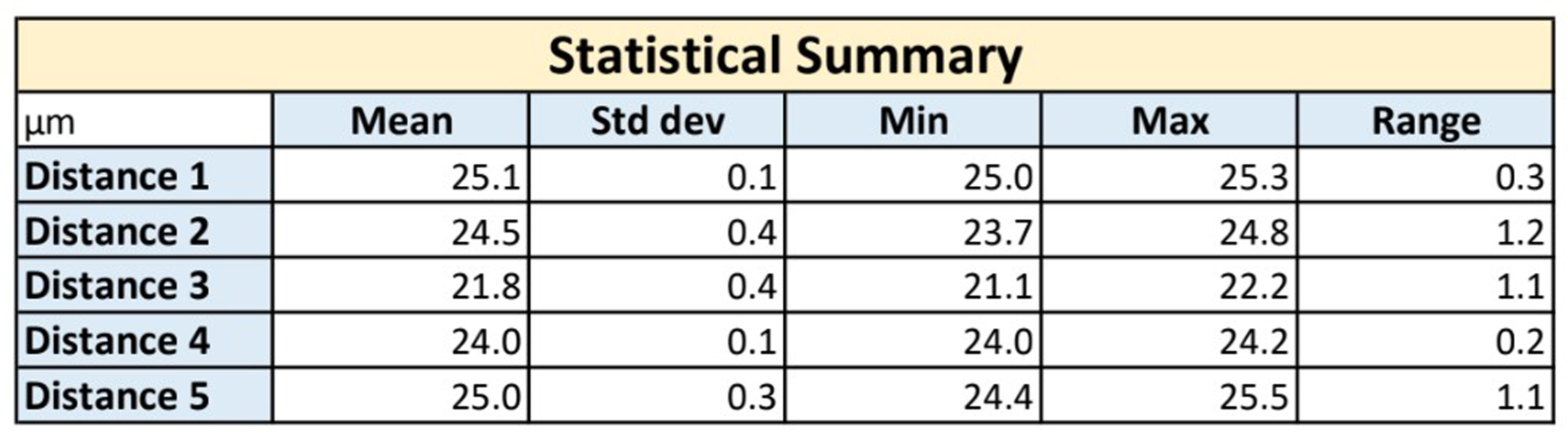

Overview summarising the results of ten separate measurement runs on the same pipe section. The repeatability of the measurement (shown as "Range" in the table) was 1.2 µm in the worst case.

Software and integration

Even the best measurement technology is of little use if it cannot be efficiently integrated into existing processes. Precise 3D data acquisition is achieved through the use of high-precision sensors in combination with motion control technology from Aerotech. This modularity allows flexible integration into existing automated manufacturing processes. The software used supports the automatic evaluation and classification of defects and geometric deviations, enabling reliable process control.

3D measurement technology as the key to quality assurance

The inspection of laser-cut hypotubes is one of the most demanding tasks in medical technology quality assurance – and the requirements increase with every micrometer of miniaturization. Modern 3D measurement systems offer the necessary resolution and flexibility to accurately capture even complex geometries.

The system used – whether confocal, image-based or sensor-based – depends on the specific application. A well-thought-out overall concept is crucial: from the choice between 2D and 3D measurement technology and the right technology to seamless integration into existing manufacturing and evaluation systems.

Those who opt for 3D at an early stage lay the foundation for stable, reproducible and efficient processes – and thus create the basis for future-proof manufacturing in medical technology.

RJ Hardt is President of Peak Metrology, a subsidiary of motion control specialist Aerotech. As a long-standing engineer at Aerotech, he has extensive experience in the development of high-precision measurement technology solutions for industrial applications. Peak Metrology bundles this expertise specifically for the field of surface measurement technology – from sensor integration to complete machine solutions.

RJ Hardt is President of Peak Metrology, a subsidiary of motion control specialist Aerotech. As a long-standing engineer at Aerotech, he has extensive experience in the development of high-precision measurement technology solutions for industrial applications. Peak Metrology bundles this expertise specifically for the field of surface measurement technology – from sensor integration to complete machine solutions.

All images: Credit Aerotech

Back to Features

Back to Features