Researchers at the University of Liverpool in the UK have demonstrated for the first time how the medical imaging technique optical coherence tomography (OCT) could provide the car industry with a practical way to automatically analyze the distribution and characteristics of the metallic flakes in car paint.

Originally a medical imaging technique

Medical professionals routinely use optical coherence tomography, invented in 1991, for applications such as diagnosing eye diseases. Meanwhile, OCT is advancing into new biomedical applications and is being explored as a tool for improving manufacturing and industrial processes. The Liverpool team reports that moving their OCT technique from medical applications to car manufacturing was a straightforward translation combined with a deep understanding of the method and the ability to build tailored instrument.

“For the flake measurement, we used a time-domain, full-field optical coherence tomography system, as it provides the high lateral resolution required,” says project leader Yaochun Shen, professor of electrical engineering and electronics at the University of Liverpool, noting that the method, however, could be implemented with other types of OCT. “For other measurements of car paints, we have previously also used single-point and line-field spectral domain OCT.”

Time-domain, full-field optical coherence tomography

“The metal flake is small — about 10 microns — thus, we needed to develop and use a high-resolution, full-field OCT system,” Shen notes. This light-based OCT technique indeed acquires real-time, cross-sectional images with micron-scale resolution, allowing manufacturers to efficiently measure in 3D the size, number and orientation of metal flakes. Automatic, real-time, in-line quality assurance would be immensely valuable during the car manufacturing process as paint that does not meet the requirements must be chemically removed and the car repainted — a laborious, time-consuming and environmentally wasteful consequence. What is more, OCT could help automotive engineers to better understand the coating process and ultimately to develop advanced car paints.

Non-contact paint analysis

Thus far, automotive manufacturers have been using ultrasound imaging to control the quality of the coating and the process. But ultrasound techniques cannot effectively image and analyze the tiny metal flakes and require physical contact with the sample rendering them useless for in-line, live QA.

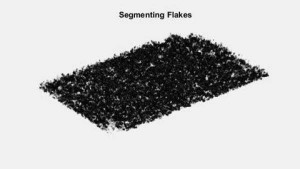

A car manufacturer tasked Shen and his team with developing a new technique for analyzing the glittery flakes in car paint. The researchers hypothesized OCT could provide a solution, as they already use OCT in their ophthalmologic research for the technique’s high resolution and ability to perform measurements without touching the sample — an ideal combination for analyzing car paint during the production process. Thus, they set out to design a 3D OCT instrument with very high lateral spatial resolution to distinguish the miniscule flakes and a high depth resolution to see the position and orientation of each one. However, Shen says, “The number of metal flakes is high, thus manual analysis is a mission impossible.” A single 3D OCT image contains too many flakes to individually measure each one. So the researchers also developed 3D analysis algorithms to automatically identify and describe each metallic flake in a sample. “We developed an automated segmentation method,” Shen says.

The experts believe existing OCT systems already come close to being viable in an industrial setting for analyzing already applied car paint. Optimizing the speed of the measurement will eventually allow for real-time monitoring of the painting process. Another thinkable application in an industrial context could be analyzing coatings of pharmaceutical tablets. “We have constructed a variety of different types of OCT, which have more potential applications than have yet been thought of,” says the professor.

The timeline for the commercialization of this new technology is “unknown at present,” according to Shen, who adds, “We need to talk with manufacturers and other potential end users.”

The work is detailed in the article “Non-destructive Analysis of Flake Properties in Automotive Paints with Full-field Optical Coherence Tomography and 3D Segmentation,” published in Optics Express.

Written by Sandra Henderson, Research Editor, Novus Light Technologies Today

Back to Features

Back to Features