Netherlands-based Snijlab is partnering with UK-based laser manufacturer Luxinar to provide engineers and creative entrepreneurs with a simple and accessible online cutting service for their production parts. The SR 15i CO2 laser source from Luxinar is integrated in Snijlab’s fully automated system to cut and mark a variety of plastic and wooden parts.

Established in 2010, Snijlab has clients across Europe in high-end manufacturing, including medical devices, industrial machinery, lighting, and electronics, who need precision cut parts to successfully bring their own products to market. In addition, Snijlab is an environmentally conscious company—powered by solar and waste materials are recycled.

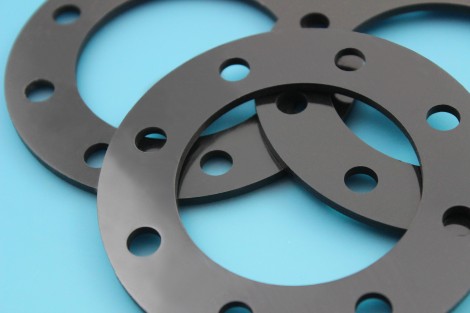

Clean surfaces on laser cut parts due to innovative laser process

The SR 15i is used mainly for cutting flat parts that vary between approximately 5mm and 500mm, an example being plastic face shields that were needed during the first phase of COVID-19.

Luxinar has been at the forefront of laser technology for over 20 years and is a manufacturer of sealed carbon dioxide (CO2) laser sources up to 1000W and, more recently, femtosecond laser sources. To date, the company has an installed base of over 20000 lasers worldwide in industrial applications environments.

Snijlab's online cutting service

Established in 2010, Snijlab offers a web-based laser cutting service, which works by clients uploading a drawing, selecting material and choosing a lead time. Being all online, the company has clients across Europe in high-end manufacturing, including medical devices, industrial machinery, lighting, and electronics, who need precision cut parts to successfully bring their own products to market. The company has integrated the Luxinar SR 15i laser into its system, which is used mainly for cutting flat parts that vary between approximately 5mm and 500mm. An example being plastic face shields that were needed during the first phase of COVID-19.

SR 15i is from Luxinar’s well-established SR series of sealed CO2 laser sources with powers of up to 250W. The SR 13i laser is the middle laser in Luxinar’s SR series, and it is designed with an integrated RF power supply and is hermetically sealed, which makes it useful in harsh industrial environments, as it can withstand dust, heat and water spray. The control interface and compact design of the unit allow for it to be easily integrated into laser-based processing machines for cutting, marking, perforating, welding, and drilling.

The laser is based on a diffusion-cooled slab principle that gives a high-quality, round, and symmetrical beam and, in addition to cutting, the SR series is used for drilling, engraving, marking, perforating, scribing and welding in a variety of industries. The 175W-rated SR 15i laser installed in Snijlab’s machine is producing between 4 and 1000+ parts per hour, depending on the material and part size.

Efficiently producing POM parts

“High reliability, good beam quality and also power stability. As our system is automated it needs to be able to produce exactly the same part for days on end. A drop in power means a scrapped product and since no operator is present, it’s hard to detect. In other machines we used glass lasers but in our experience they are not reliable enough for an application like this,” said Jiskar Schmitz of Snijlab “…approachability was a factor as well. We are new in the industry and found it’s pretty hard to get good documentation or even price information if you are less experienced and a small buyer.”

The SR 15i offers power of up to 250W. The laser is based on a diffusion-cooled slab principle that gives a high-quality, round, and symmetrical beam and, in addition to cutting. The 175W-rated SR 15i laser installed in Snijlab’s machine is producing between 4 and 1000+ parts per hour, depending on the material and part size.

Written by Jiskar Schmitz, Co-owner and Found of Snijlab and Joanna Houldridge, Marketing Communications Manager at Luxinar.

Back to Enlightening Applications

Back to Enlightening Applications