Steinbichler Optotechnik GmbH, a provider of optic measuring and sensor technology, will be presenting the innovative Steinbichler T-Scan LV / T-Track LV scanning and tracking combination at Control (hall 5 stand 5304) taking place in May in Stuttgart (Germany).

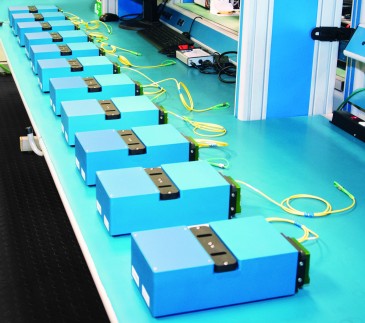

Efficient, non-fatiguing work is assured due to the compact dimensions of the T-Scan LV scanner, the company reports. The overall modular concept with the controller box and the easy-to-connect central wiring is ready for use in just a few minutes. The combination of the T-Scan LV hand-guided laser and the ergonomic T-Point LV touch probe, which makes individual point measurements quick and uncomplicated, enables precise 3D data recording for nearly all applications – particularly with large objects to be measured.

The increased measuring volume of 35 m³ of the new T-Track LV enables the scanning of objects with an overall length of up to 6 meters with very high precision and impressive speed (e.g., complete vehicle/automobile manufacturing, plant construction, agricultural technology, welding structures/metalworking, etc.). With the ‘Dynamic Referencing’ function, the system enables precise measurements, even on moving objects or objects in an unstable environment. The connection of multiple T-Track LV trackers enables even greater freedom of movement for the measurement of large objects. The change in position of a tracker thereby becomes superfluous and measuring speed is increased, even with complex shapes.

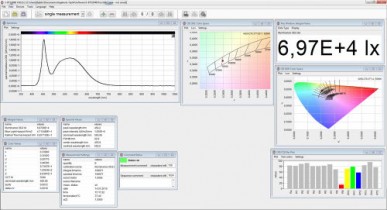

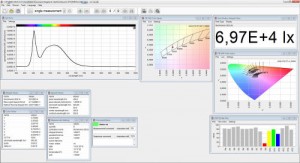

An additional Control highlight from Steinbichler Optotechnik is ‘Intelligent Light Control’ (ILC) in the Comet 6 high-end sensor. ILC enables the detection of highly reflective parts. Through the innovative and consistent advancement of strip light projection, it is possible, thanks to ILC, to dispense with the otherwise common spraying of various measurement parts. Due to the automatic recognition of components, required parameters are adjusted automatically and elaborate correction and adaption of various factors such as component length or illumination time can be omitted. The result is an increased measurement speed and the handling of the system is simplified considerably.

ILC independently analyzes the recordings of the Comet 6 sensor. In areas where there is excessive exposure or radiation due to an excessive influence of light on the component, the amount of projection light is automatically reduced. With the digital projection unit, the Comet 6 sensor is capable of projecting a multitude of gray values and can thus project a special gray value for each area of the component.

Strip light sensors, like the Comet 6, enable the quick and highly precise measuring and scanning of a variety of parts.

Back to Products

Back to Products