Pixelligent Technologies today announced that its collaborative project with the University of Massachusetts Amherst has received a grant from the National Science Foundation (NSF). Titled “Research Partnership for Scalable Metalens Fabrication,” the project aims to show that high-efficiency metalenses with refractive indices as high as 2.10 can be fabricated at commercial scale using efficient nanoimprint processes and equipment.

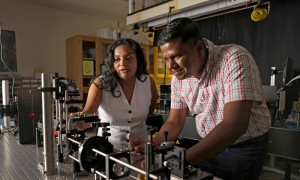

Prof. James Watkins at UMass Amherst’s Department of Polymer Science and Engineering leads the initiative. Pixelligent is Co-Principal Investigator, along with Moxtek, Inc. Prof. Amir Arbabi at UMass, who is an expert in metasurface design, is also a Co-Principal Investigator.

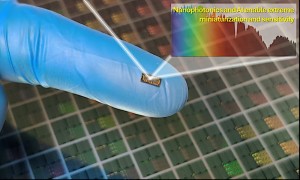

Metalenses manipulate light and eliminate chromatic aberrations. Unlike classical refractive lenses which are curved and often bulky, metalenses are flat and wafer-thin. Efficient metalenses rely on subwavelength elements with precise shape, small pitch, and critical dimensions below 100 nm. Until now, prototype lenses at this dimension have only been fabricated using multi-step subtractive processing technologies and traditional semiconductor equipment. Yields can be low, and production costs high.

In contrast, by using Pixelligent’s breakthrough PixClear® titania nanomaterials and a proprietary process designed by the Institute for Hierarchical Manufacturing team at UMass Amherst, a scalable low-cost nanoimprint-based manufacturing model will be developed to produce metalenses that deliver the high-performing optics required by next-generation products. Innovation in the space is relentless, driven by the need to miniaturize optics that enable diverse products - from augmented and mixed reality glasses that are feature-rich, yet ultra-light and stylish, to camera lenses and sensors on smartphones that improve image capture and can be embedded in the back case. The World Economic Forum identified metalenses as a top-10 emerging technology with the potential to “positively disrupt the existing order.”

“For the past couple of years my team has been working on the design and fabrication of high-performance, all inorganic metalenses using an innovative, commercializable, and cost-effective additive manufacturing approach,” said Prof. Watkins of UMass Amherst. “We believe this approach will enable our partners to be first to market with a superior product that cannot otherwise be manufactured in a scalable manner. The NSF project unites a team that will enable us to demonstrate full scale optical wafer processing. As the industry’s leading provider of ultra-high-refractive index titania nanocomposites that can meet the stringent project requirements, Pixelligent was the obvious materials partner. We are grateful to the NSF for their support of this project,” said Watkins.

Promising results are reported in this article published by the UMass team last week in the journal ACS Photonics (DOI: 10.1021/acsphotonics.1c00609).

“Once the production economics and yields of high-efficiency metalenses can be improved, product innovators will have greater design latitude,” said Pixelligent’s CEO, Craig Bandes. “That’s the goal of this project and it syncs 100% with our roadmap to provide materials that enable the next-generation applications being developed by our market-leading consumer electronics customers. This effort is already yielding results with exciting implications for industries that rely on advanced optics. We’re proud to collaborate with Jim and his world-class team at UMass Amherst, and we appreciate the support of the NSF for this effort.”

Back to News

Back to News