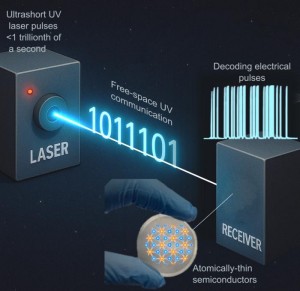

A technique discovered by researchers at the University of Exeter in the UK allows for the movement of excited charges through a non-uniform energy-gap landscape. This effect could make solar cells three times more efficient by “funneling” the electrons and holes so they can be extracted from the semiconductor more efficiently.

“Such energy gradient is realized by inducing a non-uniform strain gradient in the semiconductor — that is, by ‘pulling’ the material in a specific way,” explains Dr Adolfo De Sanctis, research fellow in the Quantum Systems and Nanomaterials Group at Exeter. “The unique feature is the demonstration of a method for creating the necessary strain gradients directly in a material, without relying on complex geometrical structures fabricated on a substrate.”

Inverse funneling enables new optoelectronic devices

De Sanctis says his team demonstrated for the first time what is called “inverse funneling,” which allows to extract charges away from the strain region. “Direct funneling,” by contrast, drives charges towards the middle of the strain region, making it very hard to extract them with electrical contacts. “Indeed, earlier works which probed this effect were not able to do so using electrical contacts,” the researcher points out. “Inverse funneling truly allows the realization of new optoelectronic devices.”

The idea of funneling charges toward the point of extraction for increased efficiency seems simple. Yet, other groups had not been able to realize this feat, thus far, for lack of adequate semiconductors: “The working principles of a charge-funneling device is based on the presence of a large non-uniform strain gradient,” the expert says, adding that in common semiconductors, the required strain levels cannot be achieved as the materials would break if strained more than 1%. A new class of semiconductors, called transition-metals dichalcogenides, however, allows to reach strain levels up to 15%. De Sanctis credits this capacity to the new semiconductors’ intrinsic nature of being layered. This means, these materials are formed by staked layers held together by a relatively weak force.

“Another key ingredient was the discovery that one of such materials — called hafnium disulphide — could be transformed into an oxide simply using laser irradiation,” De Sanctis continues. “In this way, we were able to use the interface between the semiconductor and the oxide to engineer the required strain, a unique technique which can only be exploited in layered semiconductors.”

Highly efficient hot-carrier solar cells

“Our theory shows that this technique can be used to realize a so-called ‘hot-carrier’ solar cell,” De Sanctis says. “In a realistic view, the power conversion efficiency of such devices can theoretically approach 60-65%, although the theoretical thermodynamic limit is 85%.”

Being only a few atoms thick, layered semiconductors can enable such hot-carrier solar cells, which are flexible and, thus, could be fitted around buildings, on cars and even integrated in clothing and textile products, for example. “This would make our cities, our vehicles and even our clothes part of a distributed solar farm, able to harvest the energy from the sun in any condition,” says De Sanctis.

Revolutionizing the solar cell industry

The research advance could have a huge impact on the design of the next generation of solar technologies. In fact, De Sanctis believes, “This technique can bring a revolution in the solar cell industry.” In addition to achieving higher efficiencies, new materials can now also be thinner, lighter and more flexible than previously possible. “There are still hurdles to overcome, such as the large-scale manufacturing of these materials,” De Sanctis says. “A new semiconductor industry can rise using these novel materials, with new applications which cannot be realized in the silicon industry.”

Astonishing breadth of potential applications

As De Sanctis elaborates, higher efficiency means more clean energy, which means higher quality of life, less pollution and reduced carbon emissions. Novel designs, such as lightweight, portable solar panels, could be employed in remote locations where other energy sources are scarce. The breadth of potential applications is indeed what surprised him the most about the outcome of this research work. “At first, my work was mostly dedicated to understanding a new physical phenomenon. But soon after, I realized the potential implications for green energy harvesting, and this was a big surprise for me,” he recalls. “The public response to this issue was also surprising, and I hope that this will trigger more and more research into the subject.”

Next steps

De Sanctis reminds that this research is at a very early stage. Going ahead with the work, he and his colleagues are planning to test other materials and to identify fitting candidates to use in solar cells. “Enabling hot-carriers extraction will be the next big achievement, and we are already working on it,” he reveals. “Furthermore, we will need to work in collaboration with materials engineers and companies to scale up the size of the samples and work toward an industrially feasible fabrication method.”

The research is detailed in the paper, “Strain-engineered inverse charge-funnelling in layered semiconductors,” published in Nature Communications. De Sanctis was lead author.

Written by Sandra Henderson, Research Editor, Novus Light Technologies Today

Back to Features

Back to Features