Laser Components has been working with Dexter Research Centre, a manufacturer of thermopile detectors. Thermopile detectors are passive radiation sensing devices that require no bias or cooling and generate an output in the range of micro to millivolts. The spectral absorption of these detectors is flat from the UV to the far infrared with spectral sensitivity only limited by the choice of optical band pass filters.

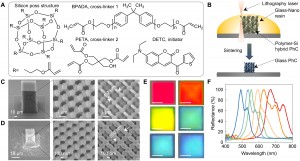

The construction of a typical thermopile detector manufactured by Dexter is shown in the figure above. The detector consists of a number of hot and cold junctions which form a thermocouple array mounted on a ceramic substrate which contains an opening. The junctions are connected with alternating n-type and p-type materials called “arms.” The cold junctions are typically thermally connected to the detector package and are located around the perimeter of the substrate opening. The hot junctions define the active area of the detector pattern and are coated with an energy absorber. They are located in the centre of the detector and are suspended on a thin membrane, thermally isolating them from the rest of the package

The voltage produced is proportional to the temperature gradient between junctions and, unlike pyroelectric detectors, thermopiles are very low noise detectors generating no 1/f or microphonic noise. Also, thermopile detectors provide a stable output for DC radiation up to a frequency limited by the time constant of the detector.

Applications include non-contact temperature measurements such as tympanic thermometers, automobile climate control and occupancy sensing, process temperature monitoring, household appliances, and radiometers; gas analysis in medical, automotive, and petroleum industries; hazard control including flame and explosion detection; horizon sensors for scientific and space, and applications.

Back to Products

Back to Products