Emerson has introduced a range of new plastic-welding solutions at the Fakuma 2018 International Trade Fair for Plastics Processing, earlier this month in Germany. These are designed to meet the demands of assembling increasingly miniaturized, complex and delicate plastic components and help manufacturers meet tighter project timelines and deliver a product line’s expected return on investment.

Emerson’s new generation of Branson ultrasonic welders is designed to support the growing demand for the assembly of smaller and more intricate plastic components. The new modular flexible welding platform will provide greater welding precision, control and efficiency, ensuring weld quality and improved operational efficiency.

At the heart of the Branson welding platform is an advanced actuation system that reduces trigger force and improves position accuracy, leading to faster, high-performance welding. This is complemented by a range of hardware and software features that simplify set-up, operation and maintenance, whilst digital connectivity supports Industry 4.0/IIoT applications that provide access to actionable performance and diagnostic data.

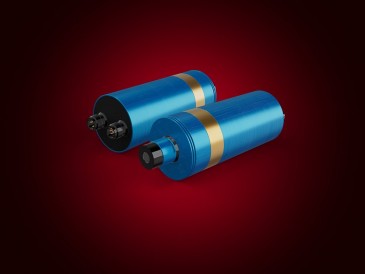

Emerson’s latest version of its Branson GLX series of laser welders, the Branson GLX-1.5, offers a plastic welding solution for the efficient assembly of small to medium-sized components with complex geometry, delicate components and embedded electronics and sensors.

The GLX series utilizes Emerson’s patented Simultaneous Through-Transmission Infrared (STTlr) laser technology. Particulate-free welds without vibration force makes the GLX series suitable for the assembly of parts requiring superior aesthetics, such as those demanded by the automotive, medical device and consumer electronics industries.

Back to Products

Back to Products