In this interview, Jose Pozo, EPIC’s CTO, talks to Michal Muniak, CEO of Solaris Optics, a leading manufacturer of precision optics.

Early career

Out of his love of buildings and design at an early age, Michal began a six-year degree in Architecture and Urban Planning at the Warsaw University of Technology in 1996. He focused on the revitalization of post-industrial areas in Warsaw. After graduating in 2002, he spent the next six years as an architect working for Artestudio and Layetana in Poland and O`Connel East and Sidell Gibson in the UK.

In 2008, he wanted to see how architectural ideas are translated into buildings in the real world and for this reason he changed direction slightly. He became an on-site project manager overseeing the construction and fitting out of commercial premises. As he recalls, this was not only a great experience in construction management but also because it gave him valuable insight into various aspects of the business.

Solaris Optics

In 2011, he set up his own business as a commercial space designer/architect in Warsaw. However, soon after creating the company, as a result of his father’s failing health, he agreed that at some point he would take over running the family business, Solaris Optics. The company had been created in 1991, in Poland by his father, Waclaw Muniak, PhD (Eng.). Since then it had grown to become Poland’s leading manufacturer of advanced precision optics and electro-optical modulators.

By 2013, it had become apparent to Michal’s father and the rest of his family that he no longer would have the strength to run the company in the way he wanted. Therefore, in April 2013, Michal honored his commitment by starting an MBA and working in the company’s Business Development Department to be trained by his father. The original idea was for Michal to take over the company after five years, but sadly, in 2015, his father passed away, so Michal had to become CEO sooner than expected.

As can be imagined, with no knowledge of optics and with just some basic knowledge of the company, becoming CEO of a precision optics company with a workforce of 60, virtually overnight, was a daunting experience. Over the next 6 months, he learned as much as he could about optics and about the company’s management and finance. This also included contacts and relations with the company shareholders. In these tasks, he was able to use his past experience as an architect, so far as it had given him skills in organizing and simplifying systems into smaller manageable tasks so that they be easier to understand.

Finally, in 2019 Solaris Optics became a family business. Michal's family bought a controlling stake from the other investors. This was a new opening in the company's history.

Company development

Since 2000, Solaris Optics has been located on its own premises in Józefów, Poland comprising 4,744m2 with a production building of 1620m², and now it employs over 70 people. The company currently is producing optical elements made of all types of optical glasses, quartz glasses, optical ceramics and crystal, ranging from cutting raw material in blocks or rods, through all standard technological processes such as milling, grinding, polishing and coating optical to framing them and a precise assembly of optical systems.

When the company stsarted out 30 years earlier, production was intended mainly for the domestic market but due to the lack of development of a photonics ecosystem in Poland, Solaris had to look for markets abroad. Its first client was Philips because of the production of optics for photolithography devices. Since then, thanks to the constant growth of the company’s manufacturing & quality control capabilities, export has increased to account for around 95% of the total production. Most of it goes to the German and Dutch markets as well as to Taiwan and Israel.

Such a large percentage of foreign customers has created some logistical problems for collaboration in terms of both distance and shipment costs. However, despite the lack of a domestic ecosystem, an advantage of being based in Poland is that it has made it easier for the company to obtain EU project funding. It is due mainly to the fact that it is easier for companies in western Europe to obtain EU funding when they form a consortium with a company from eastern Europe.

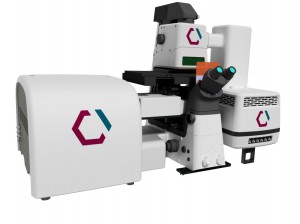

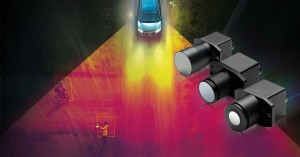

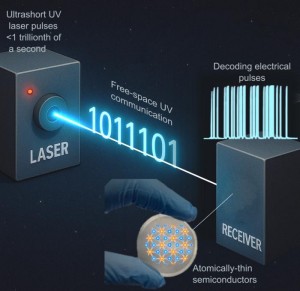

Since 2005, Solaris has been ISO 9001 certified for the production of optical components and assemblies for advanced laser and optoelectronics technologies, and now the company has an impressive range of products covering the whole range of precision optics. These include lenses, filters, mirrors, polarizers, prisms, beamsplitters, diffusers and electro-optic modulators, as well as imaging, infrared and laser optics. Solaris Optics also provides services in optical design, thin-film coatings, metrology services and manufacturing.

In 2012, Solaris set up its own R&D group for high-level optical engineering in order to help customers with the design and modelling of optical systems, technology feasibility studies, and the development of optical characterization techniques.

In regard to application fields, they work mainly in the semiconductor industry, material processing, telecommunications, lithography, imaging, and scientific research. In 2015, Solaris received an investment of €3.2 million for new production machines and measuring equipment. This enabled it to buy a state-of-the-art MRF polishing machine and enter new application fields, particularly in the space, air & defence sectors.

The future

The company is currently working on a five-year, post-pandemic strategy to improve performance in the following areas:

Effective commercialization: When Michal became CEO, Solaris Optics had a culture and mentality similar to that of a scientific institute. Since his arrival, one of his main objectives has been to make the company more business-oriented. As he points out, the manufacture of top-end optics is relatively easy to achieve as it is more or less just a matter of investment and getting the right kind of engineers. As a result, the company needs to shift its main activity from niche applications (e.g.,for space research) to the commercialization of its products.

To this end, Solaris Optics has to do two things: first, become more customer-focused, second, rather than continuing to do everything, concentrate on particular segments in order to create a stream of simplified and more specialized production.

Custom optics: While the company has several line products, one of its major strengths lies in custom optics, which currently account for around 30% of its production. Providing custom optics means having to respond to customer demands quickly and with a stream of more specialized production. Only then Solaris Optics will be better placed to respond immediately to customers who require custom optical elements. One of the advantages of providing custom optics is that Solaris is able to help its customers develop prototypes, which puts them in a good position to obtain volume orders once the prototype goes into production. The same applies to start-ups with ideas for new products, although in these cases there is an added opportunity of partnering with the start-up either as shareholders or via a contract supposed to provide the optical elements they will need to develop.

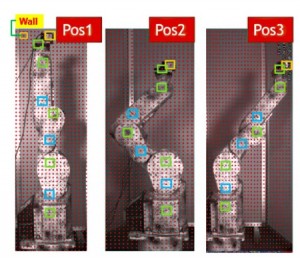

New applications for free-form optics: Interest in free-form optics has mushroomed in recent years. This is true particularly for aspherical lenses for a new generation of head-up displays and cameras. With its MRF technology, Solaris Optics aims to work more in this area. One of the problems with aspherical and free form optics is that there is little or no standardization in either shape or metrology. As a solution to this issue, Solaris engineers are in regular contact with other companies to exchange information on metrology and polishing with the aim of developing general standards.

If you started again, what would you do differently?

“I don’t think there’s much point in looking back. In any case, I wouldn’t change my educational choices. Although I may not know as much about optics as my engineers, this can be an advantage since I don’t see as many obstacles or things that are impossible to achieve as they do. Not having the brain of an engineer, which tends to be focused on technical detail, means I have the comfort of being able to have a general perspective”.

What advice do you have for the next generation of entrepreneurs?

“Firstly, it’s crucial to choose the right people you work with, especially when you are not a specialist. But it’s not only about technical skills – it’s also about finding people with the right mindset. In my first 5 years, I had to replace quite a lot of employees because I wanted to work with people with the right attitude and sensitivity.

Secondly, people often have a tendency to build a bubble around them, so it’s very important to have an external view of someone based outside the company, like a consultant or an experienced manager or scientist – someone who will give you a different perspective and challenge your assumptions”.

Written by Jose Pozo, Chief Technology Officer at EPIC (European Photonics Industry Consortium).

Back to Features

Back to Features