Since the middle of 2018, SICK has been manufacturing sensors in a digital plant at its Freiburg site featuring autonomous digital production and control processes.

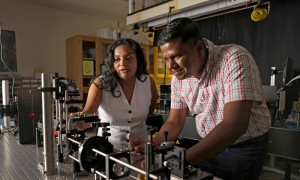

With the fourth industrial revolution in full swing, it seems everybody is talking about Industry 4.0 (I 4.0) right now: The ability to network and control machines and processes using information and communication technologies is set to drastically change production processes as we know them. The production of the future may still be in its conceptual stages right now, but it is already very much a reality for SICK: In the production facility, the 4.0 NOW Factory, at the Freiburg site, robots and employees are working side by side to produce the new SICK sensors with twelve fully automated production technology modules, four manual workstations, and a hybrid workstation at their disposal.

Production reimagined

The cellular organization of the production process allows the modular usage sequence to vary as required. Material is supplied by means of automated guided carts (AGCs). All the workflows are managed by a high-performance software system developed in-house by SICK. This contains all information relating to each respective order, such as the product properties, quantity, and details on which production steps are required for each module. The system sends the information to the machines and receives constant feedback in return. All of the contributing elements – the sensors, machines, and people – are organized remotely, networked, and are in constant communication with each other.

Full flexibility: Quick and variable

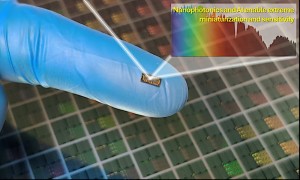

Five product families are currently in production in the 4.0 NOW Factory, with the plan to increase this to 12. The system already features the necessary equipment to bring this plan to life, allowing SICK to implement and market new developments significantly quicker than ever before. The scope is available to cover more than 500,000 product variants. What’s more, the production processes can accommodate an unlimited variety of options, which allows a whole host of diverse and bespoke customer requirements to be taken into consideration. The factory is even capable of producing small quantities on demand – and at a cost similar to that of mass production.

Utilizing and strengthening the potential of I 4.0

SICK recognized the huge potential of Industry 4.0 very early on and intends to exploit it to its full potential at its Freiburg production facility. Underpinned by several years of preparation and a high level of investment, this major project sees SICK set to play a pioneering role once again. The company has even laid the foundations for the further development of its site: “We looked well into the future on this one. In fact, our plants are capable of manufacturing products that we haven’t even come up with yet,” explains Bernhard Müller.

Back to News

Back to News