Collaborating with colleagues from other institutions and a semiconductor equipment manufacturer, researchers at the University of Arkansas have developed an optically pumped laser with germanium-tin grown on silicon substrates, potentially bringing scientists a step closer to fully integrated silicon photonics, with much faster chips and at significantly lower cost.

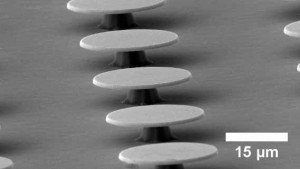

The team has demonstrated a germanium-tin laser based on direct band gap group-IV material: “The laser operates under optically pumped condition, with a pulsed laser as pumping source, at a maximum temperature of 110 Kelvin [about –261 Fahrenheit] and a wavelength of 2.5 μm,” says Shui-Qing “Fisher” Yu, associate professor in the College of Engineering at the University of Arkansas, who led the research. He says the germanium-tin alloy can be directly grown on silicon substrate, and the material growth and device fabrication are compatible with standard CMOS processes. “Since the new germanium-tin laser features low-cost and monolithic integration on silicon substrate, the optoelectronic integration of a ‘superchip' can be achieved on the germanium-tin platform.”

The germanium-tin laser is based on direct-band-gap group-IV material with a traditional lasing mechanism (band-to-band transition). Direct-band-gap germanium-tin had been achieved for the first time only three years ago, and the germanium-tin laser was demonstrated just recently. “For the ‘superchip’ applications, the monolithic integration of the germanium-tin laser on silicon substrate can be achieved, which is not attainable with previous methods, i.e., hybrid integration or direct growth of III-V-material-based laser on silicon,” Yu confirms.

Low cost, high performance

“This germanium-tin laser can be monolithically integrated on silicon substrate,” the professor notes once more. And because the material growth and device fabrication processes are CMOS compatible, the low-cost, high-performance germanium-tin laser becomes feasible. “Particularly, for the integration of optoelectronic components towards a ‘superchip,’ the previously developed silicon-based light source has not satisfied the community,” Yu tells, adding that his new germanium-tin laser could be the best light source candidate yet on the path to a superchip.

Closer to optoelectronics “superchip”

Yu explains that the optoelectronic components of the “superchip” should consist of light source, waveguide, modulator, detector, etc. He points out that while the rest components have been relatively well developed, the research outcomes regarding light sources have been less satisfactory. “The breakthrough of a germanium-tin laser offers a novel type of light source that provides a favorable integration capability, making the ‘superchip’ achievable,” he concludes.

Material growth is key to success

“The material growth is the decisive factor in this project,” the photonics expert says. “A very fundamental question is, ‘What is the maximum tin concentration that can be achieved in germanium-tin?’ “ Previous researchers, he says, had thought the precursors, such as germane, were the limiting factor and that higher tin concentration would require a higher-order precursor, such as digermane, which is expensive. However, “During our material growth process, we found that the material strain rather than chemical reactions plays the key role for the tin incorporation,” the professor reveals.

Next steps

“Since the optically pumped germanium-tin laser has been successfully demonstrated, the natural progress will be the improvement of the device performance,” Yu says. His team aims to reduce the lasing threshold and increase operating temperature, and eventually achieve the room-temperature electrically injected laser. They will comprehensively study the material growth mechanism so they can understand how to improve device performance and fabrication.

The research is detailed in the article “An optically pumped 2.5 μm GeSn laser on Si operating at 110 K,” published in Applied Physics Letters.

Written by Sandra Henderson, Research Editor, Novus Light Technologies Today

Back to Features

Back to Features