Australian researchers have unexpectedly discovered a natural phenomenon that shows it is possible to chip individual atoms out of a diamond surface using ultraviolet light. Super-resolution laser machining would open new avenues for nanoscale diamond devices, made by etching nanopatterns into the diamond’s surface.

“We've found evidence that it is possible to use an optical method for picking apart diamond atom by atom,” says lead researcher Richard Mildren, associate professor in the Department of Physics and Astronomy at Macquarie University, Sydney, Australia. The discovery, in fact, was seemingly made by chance when the team attempted to use an intense ultraviolet laser to machine a piece of diamond. Observing this effect in diamond may not be coincidence since this crystalline form of pure carbon has highly defined bonds that are relatively disconnected from neighbouring atoms.

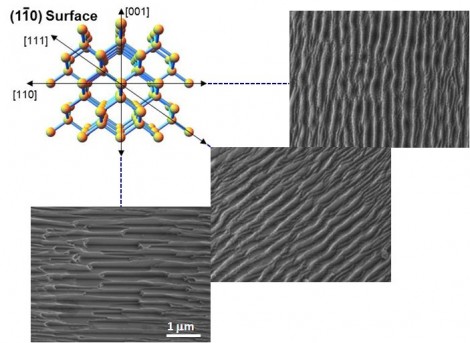

Initially, the researchers observed a carve the size of the laser beam through the diamond. However, “On very close examination of the treated surface using a high-powered electron microscope, a curious pattern of regular nanostructures was observed,” Mildren recalls. The key observation, he carries on, occurred when they varied the light beam's polarisation, the direction of the light wave's oscillating movement: The particular shape and orientation of these patterns changed depending on the way chemical bonds of surface atoms lined up with the polarisation. “This surprising observation provided the key clue that the light is interacting with the individual bonds, something that is rarely seen in nature and never before for the main structural bonds of a solid.”

Lasers, while proven for precision drilling and cutting with a “hot” beam of energy, have been known to show notoriously poor resolution at the atomic level. Adds Mildren, “On the scale of the distances between atoms, lasers were thought to be hopelessly ineffective.” Overcoming this resolution threshold would open the door to a plethora of new design opportunities for future nano-devices. Diamond has been around for thousands of years, yet “is only now gaining great importance in science and technology,” Mildren continues, sharing that low-cost production of high-quality diamond material from synthetic sources is driving developments in areas such as ultrafast electronics, quantum computing devices, medical implants and miniature high-power diamond lasers.

The phenomenon solves the heat generation problem that previously limited the use of lasers for making very small precise cuts. “The chemical bonds are broken selectively before there is any significant dissipation of heat to cause damage to the surrounding area,” says the Australian Research Council Future Fellow at the MQ Photonics Research Centre.

The Australian team has already shown it is possible to create structures in diamond of about 20 nm, the size of large molecules. “This is many tens of times smaller than what could previously achieved,” says Mildren, who believes, “much better” is possible, ultimately enabling manipulation of surfaces with single-atom precision.

The lasers used in the Australian experiments were pulsed lasers operating in the UV-C region, with a wavelength near 260 nm.

Mildren’s ultimate goal is to demonstrate selective removal of single atoms from a surface. “Achieving resolution of the size of large molecules is likely in the short term. Demonstrating single atom resolution, although it seems to be possible, may take some substantial development.” Fully understanding the observed natural phenomenon (e.g., how is the light absorbed? How are the bonds broken without significant leakage of energy into the surrounding area?) — will require new theories, possibly even new fields of study, according to Mildred. “The discovery has been like finding a new tool that was previously beyond our imagination,” he says. “Finding out what this new tool can do is also something I find particularly exciting.”

The research is detailed in the article “Two-photon polarization-selective etching of emergent nano-structures on diamond surfaces,” published in Nature Communications.

Written by Sandra Henderson, Research Editor Novus Light Technologies Today

Back to Features

Back to Features