Researchers at the Chinese Academy of Sciences have developed an aerogel film made of DuPont Kevlar fibers that makes objects invisible to infrared detectors. A successful method for hiding objects from heat-sensing cameras could be useful in research or in military and technology applications.

Novel film overcomes obstacles of alternative technologies

“We have fabricated a Kevlar nanofiber aerogel film and its phase-change composite,” says Xuetong Zhang from the Suzhou Institute of Nano-tech and Nano-bionics at the Chinese Academy of Sciences. Previous approaches to making objects invisible to heat-sensing cameras each had weaknesses — from the need for a power supply to impractical rigid materials. “The aerogel film is flexible and foldable with high porosity, large specific surface area and outstanding thermal insulation property,” notes the scientist. The phase-change composite film exhibits high thermal management capability thanks to its high phase change enthalpy, with ultralow infrared transmittance and an infrared emissivity of 0.94.

Zhang points out that compared with previous emissivity control methods, this is an adaptive IR stealth technology but without energy consumption. Compared with alternative temperature control methods, the combined structure is thin and light, and will not cause heat build-up, due to the layer structure.

Combining thermal insulation layers with IR absorption surface layer

This new stealth film does not only prove effective but it is also inexpensive and easy to fabricate. The aerogel by itself is a thermal insulator. However, the researchers coated the film’s fibers with polyethylene glycol (PEG) and a protective waterproof layer. PEG stores heat when it melts and releases heat when it solidifies. “We have proposed a unique combined structure constituted of thermal insulation layers and an IR absorption surface layer,” Zhang says.

Generally, target objects have higher thermal radiation than their backgrounds. Traditional thermal stealth materials applied as low thermal emissivity coatings are static, meaning they only work at certain temperatures. On the other hand, IR stealth materials with dynamic temperature adjustment are high in energy consumption, have low tunability, are slow to response and are typically on rigid substrates, according to the scientist. Zhang says modulating temperature, such as through thermal insulation, has been proposed as a solution for hiding infrared radiation in the past. However, thermal insulators such as blankets are generally thick and heavy, which can cause heat build-up. However, the solution proposed by the team from the Chinese Academy of Sciences seems to overcome these issues: “Our phase-change composite film can solve the problems mentioned above and demonstrates adaptive thermal stealth in outdoor environments without energy consumption.”

How it works

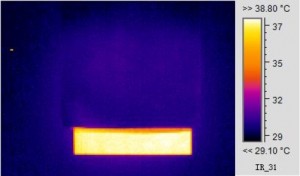

When simulated sunlight is shone on an object covered in the composite film, the film absorbs the heat yet only slowly increased in temperature, much like the surroundings. This quality is what makes the object invisible to a thermal camera. When the light is turned off — i.e., simulating nighttime conditions — the coating gradually gives off the stored heat until it levels with the temperature of the surroundings.

Applications

Such films that successfully hide objects from infrared detectors can potentially find a multitude of applications in real life: “We believe these IR stealth films can be incorporated with traditional textile to fabricate clothes or helmets for personal IR stealth,” Zhang reveals.

Developing this film, nevertheless, did not move along without challenges for Zhang and his colleagues. He explains that while the most popular dry method to obtain aerogel from hydrogel is supercritical CO2 drying, that method is complex, energy costly and not suitable for scale-up. “We found that using tertiary butyl alcohol (TBA)-water co-solvents to replace water in Kevlar hydrogel followed up by freeze-drying can obtain high quality aerogels. Thus, all the procedures are simple, efficient and convenient; no special equipment is needed.”

Speaking about the course and the results of the research work that went into the nanofibrous Kevlar aerogel film, the researcher emphasizes that the Kevlar aerogel film is flexible and robust with outstanding thermal insulation and thermal stability. “But the most surprising property is that the aerogel film can take as high of an PEG loading as about 95%, without any leakage, which is much higher than previously PCM composites,” Zhang says. “Also, this phase-change composite film exhibits an ultralow IR transmittance.”

The research breakthrough could indeed impact the design of future generations of infrared technologies: “We provide an adaptive IR stealth technology from phase-change composite films with no energy consumption,” Zhang confirms. “Therefore, the future generation of IR stealth technology should be simple, low-cost, energy-saving and highly efficient.”

Next step

Moving forward with their research work on the novel aerogel film, Zhang and his team are now planning to scale up these products for real applications.

The results of the research are detailed in the paper “Nanofibrous Kevlar Aerogel Films and Their Phase-Change Composites for Highly Efficient Infrared Stealth,” published in ACS Nano.

Written by Sandra Henderson, Research Editor, Novus Light Technologies Today

Back to Features

Back to Features