ISRA VISION is expanding its range of production automation and quality inspection technology products by taking over GP Solar and GP Inspect, and in doing so it is branching out into the photovoltaic industry.

ISRA's range of products will be able to cover each and every critical processing step, from the production of wafers to the assembly of complete modules. The goal is to offer highly precise inspection systems designed to improve performance and production efficiency. The portfolio not only includes in-line inspection systems, but also standalone solutions and laboratory measuring technology.

The inspection systems are used for inspection and measurement tasks in photovoltaic series production. The systems are highly precise and are designed to inspect objects at different positions in the wafer and solar cell production line. The measuring and inspection devices have been installed in production lines with leading manufacturers of solar cells in Europe, Asia and the United States and have proven their strong performance and precision capabilities multiple times over. They are used in complex applications.

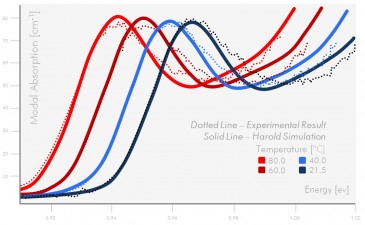

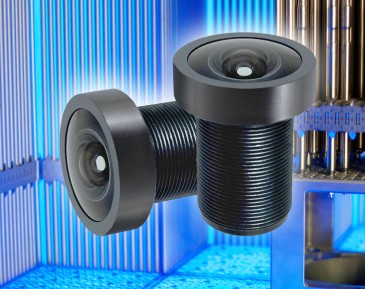

As an example, in the metalization process during which conductive fingers and busbars are attached to the solar cell, defective solar cells are identified by inspecting the quality of the metal grid on a solar cell. Moreover, the quality of the grid also provides insight as to the cause of the defect. GP PRINT-Q .Cam thoroughly inspects the print quality of solar cells. Solid process monitoring is guaranteed by a specific system in which a GP PRINT-Q FS.Cam inspects the front side of the solar cell, and one GP PRINT-Q RS.Cam each inspects every printing step on the rear side. Using the new "Advanced Rear Side Inspection", not only are red images analyzed, but UV images are also analyzed separately.

Details, which in the past had only been visible under a microscope, can now be inspected with GP PRINT-Q FS .Cam. For the very first time, a high-resolution camera can make the depth of detail usable in quality inspection tasks. Now, this technology makes it possible to even detect defects on the metal grids and their contacts on the front side down to ranges of less than 40µm. This will be an important technical feature for highly efficient solar cells in the future that will have even thinner front contacts.

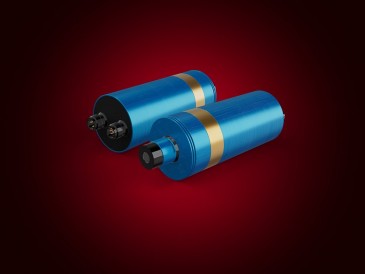

To detect micro-cracks, ISRA can now offer GP MICRO-D.Cell, a non-contact in-line inspection system. This does not impact the metal grids or the grain boundaries in multicrystalline solar cells. As a result of the inspection, problems are uncovered in the production process, thus shortening operation time and increasing the processing system's output.

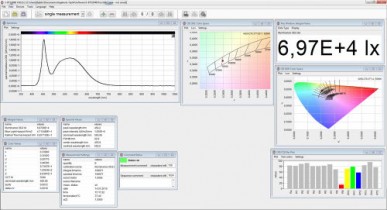

In addition, ISRA also offers a standalone system for quality classification. The standalone GP.TEST-UNIT has the capability to stack separate wafers and cells, to test them and to sort them by quality based on the measured results. This system thus gives manufacturers with already existing production lines or with limited production space quite a bit of added value.

In the photovoltaic market, ISRA is focusing on offering systems designed to automate production processes, fulfill quality assurance tasks and reduce costs, all of which are a must, especially in challenging market phases. The more than 1,000 systems installed in production lines of leading manufacturers around the world substantiate how very beneficial they are for manufacturers. ISRA's global network of distribution and services offices with 25 locations around the world is now being reinforced by a sales team in Asia as a result of the GP acquisitions.

Back to News

Back to News