Osram Opto Semiconductors is launching two new high-power versions of the Osram Ostar Projection light-emitting diodes (LEDs) for projectors with a brightness of up to 1700 lumen (lm). According to the company, because of the optimised product design the LEDs offer high luminous flux from the available chip surface. Between 1000lm and 8300lm can be produced depending on the colour and the LED version. An anti-reflective (AR) coated glass cover, instead of the usual lens, together with external optics ensures that the light is well-bundled.

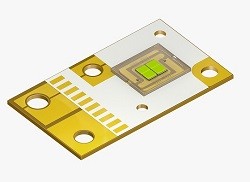

The two new LEDs offer luminous flux that can be used in office projectors with brightness levels of up to 1700lm. At the heart of the product is a 2 square millimetre (mm²) LED high-current chip based on state-of-the-art thin-film and Osram’s UX:3 chip technology. The two LED versions contain two (P1W) or four chips (P2W) with a total luminous area of 4mm² and 8mm², respectively.

In LED projectors three LEDs in the colours red, green and blue serve as the light source. The LEDs are pulsed one after the other (colour sequential mode), making the colour filter wheel used in classic lamp projectors superfluous. The high output of the new LEDs comes from the latest chip technologies and Osram ceramic (C²) conversion technology for a particularly efficient green (see Photo 1, top of page). The P2W version emits light pulses with intensities of 1000lm, 2500lm and 8300lm for blue, red and green, respectively. These high brightness levels require current pulses of up to 32 amperes (8 amps per chip) and an optimised product design to efficiently remove the resulting heat.

According to Stefan Morgott, responsible for Projector Applications at Osram Opto Semiconductors, the four high-power chips of the P2 are connected in parallel. Then the new Ostar Projection LEDs generate their maximum brightness, opening the door to use of LED projectors in offices and classrooms.

Photo 2: Osram Ostar Projection version P2W makes it possible for office projectors to be designed with system outputs of up to 1700lm. (Picture: Osram)

Osram Ostar Projection enables light to be routed as efficiently as possible through the optical system, which is restricted by the étendue. (According to Wikipedia, “étendue” is a property of light in an optical system, which characterizes how "spread out" the light is in area and angle.) The étendue of the LEDs is retained and, in conjunction with external optics, produces an extremely narrow beam of light. Étendue describes the relationship between the emitting light surface and the projected light surface.

To keep the thermal resistance and, therefore, the temperature rise at the LEDs at an extremely low level, the chips are placed directly on a copper plate and not in a classic LED package. They are screwed down to improve the connection with the heat sink.

The two new Osram Ostar Projection LEDs will be premiered at the International CES 2014 technology exhibition which takes place on 7-10 January 2014 at Mandalay Bay in Las Vegas, Nevada (US). Volume production on the Osram Ostar Projection LEDs is due to start in March.

Photo 1 (top of page): Power pack: C² conversion technology (ceramic conversion) and state-of-the-art chip technologies are behind the high performance of the Osram Ostar Projection LEDs. (Picture: Osram)

Back to Products

Back to Products