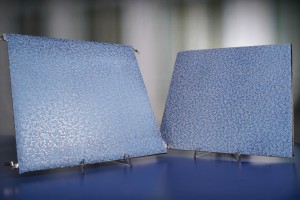

SUSS MicroOptics is setting up an excellence center for the manufacturing of wafer-level optics (WLO) in order to meet the increase in demand for precision optics applications. Among the various structures that can be manufactured at wafer-level, freeform micro-optic arrays are one of the most challenging, as they have no rotational symmetry. Thanks to this property, they can generate new light distribution patterns, correct for aberrations, as well as improve miniaturization of the optical systems. This will be key for driving the volume production of new optics for volume markets, such as automotive, transportation, lighting, augmented reality, medical, datacom, consumer electronics etc. The excellence center will be part of 800 m2 of new cleanroom space currently build in Neuchâtel and certified for the main markets targeted by SUSS MicroOptics.

The expertise of SUSS MicroOptics, based on imprint technologies, enables the production of the last mile in optics: the so-called freeform micro-optics, mainly optical diffractive, refractive or reflective components with no rotational symmetry. Until now most freeform optics applications have been in niche markets, such as space and others. Recently however, high volume applications in consumer markets especially in automotive, mobile phones, lighting and high-end cameras have emerged. According to SUSS MicroOptics, the goal is to enable volume manufacturing from pilot production all the way to high-volume production in Europe and in particular in the city of Neuchâtel, Switzerland. Neuchâtel was chosen as the location because of the city's long-standing connection with the high-end watch industry and its role in transforming expensive, low-volume technologies to higher volumes, keeping high quality standards while reducing costs.

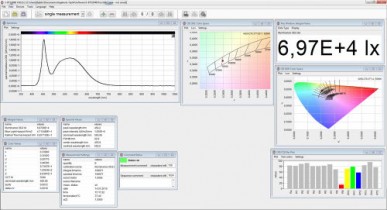

The SUSS Excellence Center will use SUSS MicroTec's manufacturing equipment to provide manufacturing services which can be scaled up to contract manufacturing.

Back to News

Back to News