STIL MARPOSS is a company that produces optical measurement instruments based on proprietary chromatic confocal Imaging technology. Founded in 1993, the company is based in Aix-en-Provence, Provence-Alpes-Cote D'Azur. Jose Pozo, EPIC’s CTO, spoke with Cosimi Corleto, Managing Director, about the partnership with measurement specialist MARPOSS, the ability to embrace new manufacturing trends, and the development of a repeatable vision system based on a camera that functions without the need of an external light source.

Early career

After graduating with a BSc in Thermodynamics from the Institute of technology in Ville-d'Avray, followed by an MSc in Engineering from Conservatoire National des Arts et Métiers (CNAM), in 1987, Cosimi began his career at Renault. In the mid-80s, Renault had introduced lasers and robotics into the manufacturing process and Cosimi’s first job was to work on the creation of a robot simulator to facilitate welding processes. He then moved to Valeo, where he helped to develop measurement technology to control the flow of temperature inside the car.

In 1989, with the aim of gaining experience with an international industrial company, he joined Schlumberger as a sales engineer responsible for the company’s range of pressure sensors they were supplying to the aerospace industry, particularly for the Airbus A320. When the division he was working in at Schlumberger was sold, Cosimi moved to the UK, where he gained further international experience in sales and marketing in the sensing market working for Solartron, a world leader in linear measurement sensors and dimensional gauging probes.

In 1999, he moved back to France to take up the position of Business Director for Solartron France with responsibility for sales in southern Europe. Then, in 2006, Solartron was acquired by the US multinational Ametek, a global manufacturer of electronic instruments and electromechanical devices. Cosimi was offered the position of Commercial Director Europe and stayed with Ametek for the next 9 years, ending up as the company’s Business Development Manager.

His main role was to travel the world collecting market information to deploy products and to run marketing operations across the company. For Cosimi, it was a fantastic experience because not only did the job enable him to gain valuable cross cultural experience it was also the ultimate experience in terms of marketing know-how. As he points out, the American approach to business intelligence and efficiency in business management is unmatched as it’s based on very developed strategic understanding and tactical deployment.

Toward the end of his time with Ametek, the company moved away from a focus on organic growth and began a series of acquisitions. Cosimi was given the task of identifying emerging technologies and companies with the right skills and production techniques that could be considered targets for acquisition. This was also invaluable experience, and over the 9 years he was with Ametek, company turnover grew from 2 to $8 billion.

STIL

From the very beginning of his career, Cosimi was aware of the strategic and economic importance for France to develop its own technology and a robust ecosystem to support French high-tech manufacturing and innovation. To this end, he became active in the French College of Metrology (CFM), an association set up in 2002 to disseminate knowledge on metrology and the control of the measurement processes in the industrial and economic fabric. He also joined SYMOP (Syndicate of Production Techniques and Machines) and in 2007, became President of SYMOP’s Measure & Vision Department.

Through contacts made in his work for CFM and SYMOP, in 2015, Cosimi was approached by the owners of STIL SAS, who, wanting to keep the company in France, offered to sell the company to Cosimi. STIL, which stands for Industrial Sciences and Techniques of Light, specialized in optical measurement instruments based on their proprietary chromatic confocal aberration and chromatic white light interferometry technology.

For Cosimi, the offer was too good to turn down; firstly, because STIL’s famous technology would stay in France, and secondly, because after 30 years in the industry at and the age of 50, he was looking for a new challenge. Accordingly, he joined forces with a venture capitalist and in 2015, acquired the company.

Company development

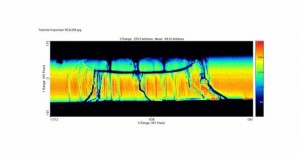

STIL had developed and patented two novel measurement technologies. The first, was Confocal Chromatic Imaging, which uses chromatic coding of space to produce a continuum of monochromatic images to provide reliable, accurate and reproducible dimensional measurements with extremely high resolution. The second, was an interferometric method based on Spectroscopic Analysis of White Light Interferograms (SAWLI) to measure the air gap thickness between reference plate and sample. The advantage of this system is that unlike most other non-contact profilometric techniques, the reference plate and sample are fixed together so that measurements are unaffected by vibrations.

The company had designed two families of sensors based on this technology: point sensors from 0.1mm up to 100 mm measuring range; and line sensors from 1.35 mm up to 4 mm line length with different measurement measuring ranges.

These high-resolution non-contact sensors could be used on any type of material i.e., metal, glass, ceramic, semiconductors, and plastic and had applications in most sectors of industry, from high precision instruments in metrology or research laboratories to quality control tools on production lines.

Over the next four years, Cosimi implemented a strategic development plan for these products, which involved expanding target markets to include electronics, automotive and aerospace industries. The plan also gave the company a more international dimension by focusing on markets in Asia and the US, as well as Europe.

STIL MARPOSS

After 4 years, however, it had become apparent that on its own, STIL did not have the financial resources to grow at a pace fast enough to compete in a globally competitive environment. As a result, in 2019, Cosimi and his investor partner made the decision to approach MARPOSS, a world leader in measurement technology, with a view to forming a partnership.

Since then, as part of the MARPOSS group, STIL has been able to tap into an extensive infrastructure and portfolio of customers particularly in Asia, who currently account for 60% of turnover. More importantly, it has enabled STIL to do what it does best – be innovative, develop its technology and solve customer problems.

In this regard, STIL has extended its product lines to include line cameras to bring microscopy directly into the production line and a new family of point sensors to address any kind of application from semiconductors to the aerospace industry.

The future

For Cosimi, STIL’s future looks good. Firstly, thanks to MARPOSS, the company has access to an extensive portfolio of customers in a worldwide network covering a wide range of application fields in the growth areas of semicon and electronics, automotive and aerospace. STIL’s aim is to bring its non-contact technology to these customers to allow them to implement efficient quality control, not only in post-process, but also directly in-process.

Second, STIL has the innovative ability to provide solutions arising from new trends in manufacturing, such as the move to downsizing components for virtually all markets from electric vehicles and semicon to biotech and the watch industry. Not only will this require measurement devices, but also the ability to ‘see the invisible’ i.e., the capability to detect cosmetic defects using AI-based machine vision.

Third, there is a trend toward smart manufacturing based on AI. As Cosimi points out, rather than giving a definitive judgement, AI is about providing the probability of a good or bad product. This requires both robust data and robust modelling right from the start, which STIL achieves by running not one but several algorithms in parallel. In this context, STIL is working on a repeatable vision system based on a camera that functions without the need of an external light source; consequently, there is no shadow effect and information can be captured directly and consistently.

If you could start again, what would you do differently?

“To be honest, not much; my career choices, for example, opting to acquire STIL have all been the right ones. I’ve also been quite successful finding the right balance between my work and my private life and I’m particularly proud of the contribution I’ve made to the development of the French metrology industry.”

What advice do you have for the next generation of entrepreneurs?

“To run a successful company in industry, it’s not enough to know only one culture. Today, business is global, and you will need to acquire knowledge and experience of the best practises from around the world; for example, American marketing strategies and techniques, the speed and adaptability of companies in Asia and the international vision and operational excellence of multinationals like MARPOSS.”

“While you should never forget where you come from, collecting this knowledge and the skills for implementing the knowhow will mean spending part of your life living and working in different countries and leaning new languages. Acquiring this vision will require an open mind to what's happening around you, and although it may take some time, the experience you’ll gain will be invaluable at both a personal and professional level.”

Written by Jose Pozo, Chief Technology Officer at EPIC (European Photonics Industry Consortium).

Back to Features

Back to Features