Every object emits heat in the form electromagnetic waves, and sampling the energy radiated into space allows the measurement of the temperature of the object without ever having to touch it. The wavelength of the light emitted by the object depends on its temperature, with hotter objects generating light at shorter wavelengths. The response of most detectors used to measure electromagnetic radiation is in some way wavelength dependent. Thermal detectors have the widest wavelength response, with the limiting factor being the transmission window used to protect the sensing element. Thermopile detectors are suitable for this application, with high temperature stability, excellent signal to noise and low cost.

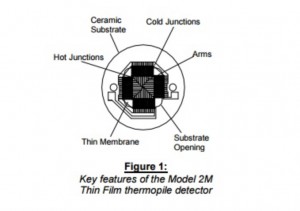

Laser Components has been working with Dexter Research Centre, a manufacturer of thermopile detectors. The detector consists of a number of hot and cold junctions, which form a thermocouple array mounted on a ceramic substrate that contains an opening. The junctions are connected with alternating n-type and p-type materials, called “arms.” The cold junctions are typically thermally connected to the detector package and are located around the perimeter of the substrate opening. The hot junctions define the active area of the detector pattern and are coated with an energy absorber. They are located in the centre of the detector and are suspended on a thin membrane, thermally isolating them from the rest of the package.

The voltage produced is proportional to the temperature gradient between junctions and, unlike pyroelectric detectors, thermopiles are very low noise detectors, generating no 1/f or microphonic noise. In addition, thermopile detectors provide a stable output for DC radiation up to a frequency limited by the time constant of the detector.

Back to Products

Back to Products