Lasers often need to be tuned to an identical wavelength, depending on their use. The problem is that the wavelength-measuring instruments can be more expensive than the lasers themselves. Now, researchers at the University of Melbourne, Australia, have built a diffraction spectrometer that can tune lasers with better than one part-per-million accuracy. The device — constructed in a straightforward manner from inexpensive components, including an ordinary webcam — is cost-effective and accessible enough to make it feasible to provide precision measurements for every laser in a laboratory.

Associate Professor Robert E. Scholten in the School of Physics at the University of Melbourne and his colleagues set out to see how far they could push a very "ordinary", routine technology. “Everybody knows that old-fashioned diffraction grating spectrometers are only good for nanometer resolution,” Scholten says. “I had this idea that if we used good optics, a single-mode optical fiber and a common webcam (which has very small imaging pixels) we could do better. Some simple back-of-the-envelope calculations were very promising.” The team implemented their theory, cobbled together an instrument and, indeed, achieved better than picometer resolution.

Tuning a laser to a particular wavelength can be challenging. “First of all, you need to know what the wavelength is; you need some way to see the effect of whatever adjustment you are making. And for many applications, you need part-per-million resolution, i.e. to within a few picometers,” explains Scholten, who is also co-author of the study “Compact diffraction grating laser wavemeter with sub-picometer accuracy and picowatt sensitivity using a webcam imaging sensor” that was published the American Institute of Physics's journal Review of Scientific Advances.

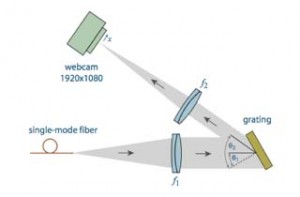

Sticking to their goal of keeping the instrument uncomplicated, Scholten’s team opted for a conventional spectrometer design. “Light from the laser is ‘bent’ by a diffraction grating, i.e., diffracted by some angle where the angle depends on the wavelength. The diffracted light is detected with an imaging sensor; we take advantage of the very high resolution and sensitivity now readily available with inexpensive consumer-grade webcams,” Scholten describes. “We also use a single-mode fiber to couple the laser light into the device — normally a big headache but because the webcam is so sensitive, it is very easy to get enough light through the fiber. The single-mode fiber defines a very small source; we image that source onto the webcam using a couple of good lenses. In combination, the diffracted light becomes a very small spot on the sensor, and with the small pixels we can measure the angle to very high precision.”

Scholten affirms his instrument is very easy to use, very easy to build and yet achieves very high resolution. “A high school student could build it using spare parts and a little pocket-money, and then detect the quantum nature of matter, like the two colours of light in an ordinary sodium street light.”

In a typical lab, there are many more lasers than instruments to measure their wavelength, because the measurement instrument costs much more than the laser. “With our device they can have a separate wavelength-measuring device on every laser, and constantly monitor each one simultaneously,” Scholten proclaims. His invention offers a solution to an essential problem many labs needing to precisely tune all of their lasers to a given wavelength face. “When one drifts, the experiment doesn't work properly — but it's hard to work out where the problem lies if you only have one wavelength-measuring instrument. That can be solved with a little spectrometer like ours on each.”

What’s next? “I'd love to commercialise it, so that I have access to commercial versions of these devices in my research,” says Scholten, who is currently prodding MOGLabs, a diode lasers and electronics lab he is involved with, to produce a low-cost and practical implementation. The physicist predicts the technology to be available on the market in about 12 months.

Written by Sandra Henderson, Research Editor, Novus Light Technologies Today

Back to Features

Back to Features