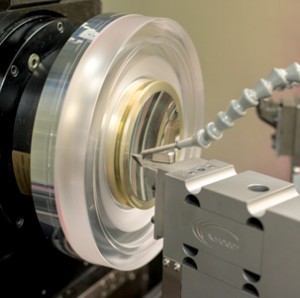

Empire Precision Plastics, a manufacturer of injection molded opaque parts and optics, will feature its molded and diamond turned polymer lenses at the 2016 SPIE Photonics West exhibition, 16 to 18 Feb. in San Francisco, California (US).

Empire provides injection molded polymer optics, single point diamond turning, thin film coating and multi-component sub assemblies for medical device, aerospace and industrial programs. The company helps customers cut costs considerably by integrally molding an optical element with other features such as frames, tabs or mounting brackets.

As a supply chain partner, Empire’s process is designed to scale, from prototype to volume production, assembly and inventory. With their in-house single point diamond turning system, Empire can create plastic spheres, aspheres, parabolic mirrors and other optical components without the added first step of building an injection mold, which lets customers meet early product demands on a short timeline.

Empire is also nearing completion of an expansion, which includes 4,000 square feet of white room space and additional automation systems to streamline medical and optical molding and assembly. The company has added in-line laser engraving to its capabilities in order to improve quality and reduce supply chain risk by allowing for improved tracking of medical devices and firearms.

For more information, visit Photonics West booth 633 in the New York aisle.

Back to Products

Back to Products