Sick has released the Inspector PIM60 vision sensor, which has a capability for high-speed inspection that machine builders and systems integrators, as well as customers in consumer-goods manufacture and packaging operations, may find useful. According to David Hannaby, Sick (UK) product manager, Imaging and Measurement, the new measurement tools support automatic rejection of out-of-specification products and provide feedback to improve the efficiency of a process.

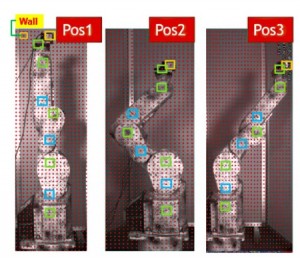

The Sick Inspector PIM60 provides integral quality inspection with a capability to measure diameters, angles and variable distances. Its new measuring tools make it possible to verify dimensions and assess product acceptability, with pass or fail verification.

The calibration capability of the Sick Inspector PIM60 enables reliable inspection of moving or rotating parts, even when the sensor is tilted or using wide-angle lenses. The result calibration function also makes it possible to output measured values as millimetres so that they can be used directly for robot or gripper control.

The Sick Inspector PIM60’s integral web server enables operators to monitor production processes simply with an on-screen interface that can be customised to meet customers’ graphic and layout requirements, making visualised data interpretation easier.

The Inspector PIM60 offers broad connectivity enabling simple or complex data to be output over multiple platforms and protocols. The results can be output via Ethernet/IP or TCP/IP.

Back to Products

Back to Products