Short-wave infrared (SWIR) InGaAs and Electron Multiplying Charge Couple Device (EMCCD) offer the cutting-edge imaging technology for visually inspecting silicon, CIGs and CIS-based solar cells. Each has distinct advantage and disadvantages in terms of sensitivity, characterization time and cost.

Because solar cell inspection relies on imaging the photoluminescence or electroluminescence signals from a wafer to characterize it, imaging devices must be chosen for their range of sensitivity. The peak emission for silicon occurs at about 1150nm while it is around 1330nm for CIGS and CIS.

This value is out of the range of sensitivity for silicon based detectors, such as traditional CCDs. Not only is their quantum efficiency traditionally measured up to only 1000nm, but very long integration times are required to acquire meaningful images, which is impractical in industrial applications.

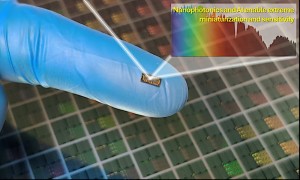

Shortwave infrared (SWIR) InGaAs technology directly detects the electroluminescence emitted at 1.3µm by solar cells and ensures their quick characterization (within milliseconds) during manufacturing.

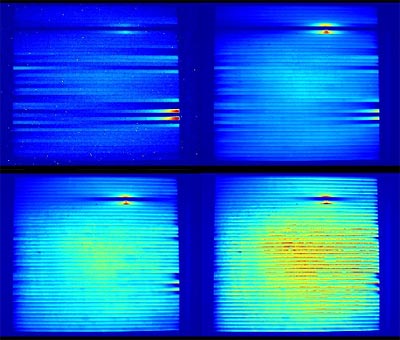

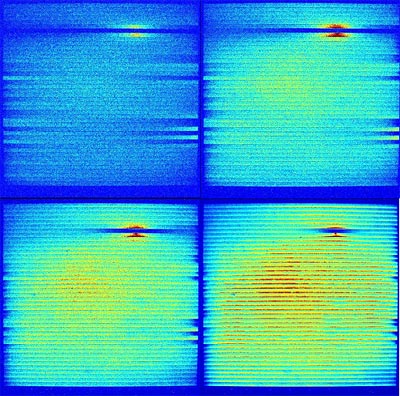

Figure 1: Image taken with Raptor’s Owl, SWIR InGaAS camera of CIGS from 30mA to 620mA and 50ms to 4ms exposure times.

The downside to SWIR, however, is that it offers low field of view and low resolution (320x256 pixels of 30µm or 640x512 pixels of 15µm), and it can be an expensive proposition.

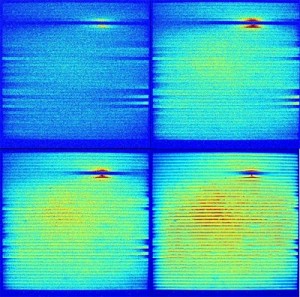

In contrast, EMCCDs offer an interesting solution by combining larger field of view and resolution (1004x1002 pixels of 8µm), for a better cost than SWIR.

Making use of its high sensitivity in the near infrared (NIR), an EMCCD is capable of detecting the edge of the electroluminescence signal with exposure times short enough to achieve over 10fps.

Figure 1 and Figure 2 show the same solar cells under similar bias current imaged by a SWIR or an EMCCD camera. The defects are clearly visible using both cameras.

Figure 2: Imaging of CIGS taken with Raptor Falcon EMCCD camera from 80mA to 600mA and 500ms to 300ms exposure times.

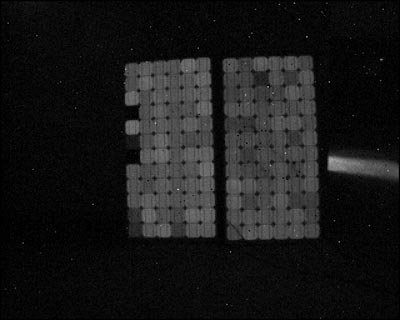

In addition to characterizing solar cells during the manufacturing process, PV power plant operators are using imaging technologies to detect problems with solar cells to maximize energy output and decrease plant down-time. This requires being able to quickly identify the solar panels with defective solar cells. It is performed on a large range of panels, which are driven under reverse bias and quickly scanned by either a SWIR or EMCCD camera in video mode.

The cells that are either damaged or operating at lower efficiency are immediately apparent, allowing the identification of the panels that need to be replaced in order to restore the overall efficiency.

Figure 3: Video taken with Raptor’s Owl SWIR camera of solar panels with variable current at 30 fps. The defective cells are clearly visible.

Figure 4: Video of the same solar panels taken with the Raptor Falcon EMCCD camera with variable currents at 20 fps. Again the defective cells are clearly visible. Contrast could be improved using a visible filter.

In conclusion, both technologies, SWIR and EMCCD work well for the characterization of solar cells. They offer a choice of solutions to suit a range of applications and customer’s requirements: SWIR allows for the fastest imaging albeit with a limited resolution and at a higher cost, while EMCCD offers higher resolution and better cost alternative at a more limited frame rate.

Written by Jean Edouard Communal, a regional sales manager with Raptor Photonics based in Northern Ireland.

Back to Features

Back to Features