A revolutionary new digital pathology invention involves a robot that can carry out the previous tedious task of medical analysis of biological tissue in a fraction of the time, with a lower rate of errors, and the ability to deliver much more data. Why is this so important? Scientists believe these advances will increase the accuracy of diagnoses and change the way we understand disease.

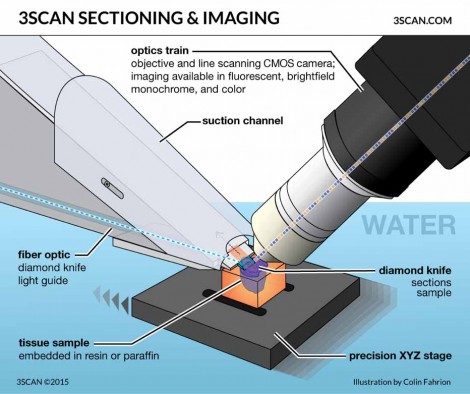

While histotechnologists usually cut slices of tissue by hand, a new scanning microscope technology that relies on knife-shaped diamonds– known as the serial sectioning technique – shaves off slivers so thin they are almost transparent to the human eye. Once enough tissue is collected, the technology can create a 3D spatial mapping of the cells, allowing scientists to “zoom” in to a cellular level, which means assessing areas in detail, with extreme accuracy.

3Scan is a digital pathology enterprise co-founded by Todd Huffman (CEO), Megan Klimen (COO), Matt Goodman (CTO) and Cody Daniel (Mechanical Engineering and Manufacturing) in San Francisco, California (US). The company won a $1.6 million grant in 2004, which they put to use developing the Knife Edge Scanning Microscope (KESM). They gained licensing in 2008, and fully developed the KESM in 2011 when their first sale was to DARPA in 2011.

They searched for a way to cut soft-biological tissue in a way where it was both microscopically thin and transparent enough to deliver more precision and accuracy for scientists. The cut of the tissue is of prime importance to 3Scan. Unlike traditional pathology where small sections of tissues are examined, at 3Scan, tissue mass is sectioned at a micron level, stained, then looked at under a digital microscope. The KESM cuts and scans serial sections at the same time through the entire mass that allows for a precise cut and examination of the sample. The thinness of the cut allows illumination of the cell, and for terabytes of data to be processed because the entire mass of the tissue is scanned. Along with the revolutionary style of cut, this Knife Edge Scanning Microscope also gathers the resulting sample with the same detail as a microscope.

There are two major reasons why this type of serial sectioning technique is the future: workflow efficiency and tissue quantification. By combining the slicing and scanning, the automation reduces the time needed to collect large volumes of data. KESM significantly improves tissue quantification, by comparing quantity and quality of the tissue sample at the same time; the results are precise significant differences are seen between a 3D tissue sample and a 2D tissue sample. By comparison, today’s pathology samples, sectioned by human hand and examined by human eye are gained by the same methods used in the Victorian era. By transitioning to automated technology and a mechanism that precisely cuts and examines with highly sensitive cameras, pathology has entered the digital age. This gives doctors the ability to look at every cell in a biopsy sample, rather than only one small slide from that sample.

How does the technology work?

The physical instrument itself contains three major components: the knife arm assembly, the optics train and camera, the stage and water bath. The most important feature is the diamond knife arm assembly. It functions as both cutting tool and the source of light for the microscope. The channel on the underside of the knife arm contains a fiber optic cable that connects the LED light source to the back of the diamond knife, providing illumination that is transmitted through the tissue section to the line scan camera. The KESM brings together elements of machine vision, automated serial sectioning, micromachining, advanced optics, and robotics to produce 3D images that can be used to quantify, manipulate, and analyze tissue structures.

Analysis of tissue is a critical foundational task in many medical processes. Most often tissue analysis is completed to diagnose illnesses, conduct medical research and DNA analysis. This customized software can enable high throughput and quantitative image analysis of diseases such as cancer and other tissue ailments.

“3Scan’s automated histology platform fills the gap between radiology and pathology by allowing large-volume high-throughput imaging of tissue and tissue scale diseases. This type of imaging technology is essential if ever we want to be able to use the power of modern computing to improve pathology outcomes.” Megan Klimen, 3Scan COO and co-founder

In order to keep up with innovative medical technology, 3Scan developed KESM to produce a cut on the tissue as thin as possible while integrating imaging into the same movement. This technology is innovative because of the speed it takes to cut, image and analyze the sample. Once enough tissue is collected, the system can create a 3D spatial mapping of the cells, allowing scientists to “zoom” in to a cellular level, which means assessing areas in greater detail, and with extreme accuracy.

“The KESM is able to simultaneously light and scan tissue samples, and because it produces many scans of the tissue, we can apply algorithms to the images and spatially index each pixel to build 3D images of the model,” said Todd Huffman, 3Scan CEO and co-founder.

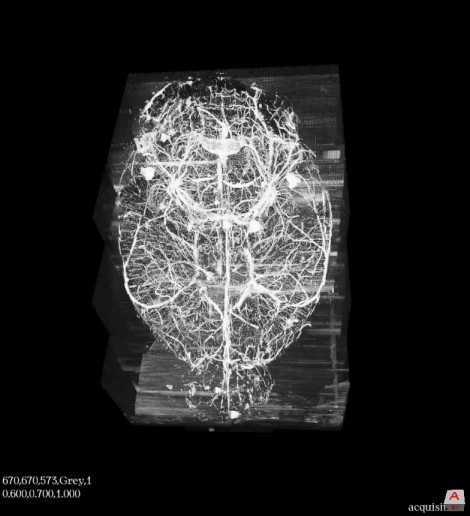

Spatial biology within tissue samples is very complex and very difficult to understand these images in 2D, at 3Scan the scans are converted into 3D models for a more detailed look. With the KESM, 3Scan are the first histopathologists able to render 3D imagery based on micron level scans. The speed and precision of this technology enables a faster and more accurate diagnosis and, in some cases, earlier detection and management of disease.

Mapping the efficiencies

To imagine the immense benefits that the KESM has had in the pathology space, consider this: a pathologist can examine up to 350 sections of human tissue per day, across more than a hundred different cases. The KESM can slice approximately 3,600 sections per hour or more than 28,000 per day across many masses of tissue. The results achieved are also far more detailed, capable of detecting cancerous cells and even malignant cells that may still exist in tissue after chemotherapy treatment.

Computing biological differences within an organ, or between organisms, is especially useful for animal models used in pre-clinical drug discovery research in a pharmaceutical trial. This enables quantification of microvasculature and may provide insight into various diseases, such as Alzheimer’s, diabetes, and cancer. By examining large volumes of tissue at maximum light microscopy resolution with high throughput, scientists and pathologists can improve the accuracy of morphological assessment and identification of normal and diseased tissue states.

At the earlier stages of its development, 3Scan was only able to capture their results in a grayscale appearance. Due to the need of specific technologies used in the KESM, they required a specific type of camera to excel their technology into color. Teledyne DALSA was able to provide 3Scan with the technology they needed to capture images in color with the Piranha CMOS and Piranha 4 4K color line scan cameras. 3Scan stains tissue before it goes onto the KESM, traditionally, the tissue would be placed on a slide and put into a machine to be stained. With 3Scan, they stain the entire piece of tissue to be able to illuminate certain anatomy within the tissue. It is important to see color to display where in the anatomy color has stained.

Todd Huffman remarked, “There are very few companies that produce cameras that have the performance capabilities that we need. Teledyne DALSA provides the sensor, the dramatic increases in pixel count, sensitivity of sensors and the array of collections that we need.”

Automating the traditional pathology workflow

By combining sectioning and imaging into a single step, a large part of the traditional pathology workflow is automated. This allows for a greater speed, precision, throughput, and scale at which tissues are digitized. To handle high-resolution data of over a terabyte per cm3, sophisticated data processing software is applied to model 3D tissue reconstructions, providing interactive image views, and applying quantitative analytics. This allows quantitative analysis to be performed on 3D image stacks of whole mouse organs, which is extremely difficult, expensive, and time-consuming with traditional manual techniques due to the size and lengthy experiments. Mouse organs are heavily relied on in academic research and early pharmaceutical research; they are beneficial in the pre-clinical phase of pharmaceuticals and are critical to advancing medical research.

With the type of image processing and data collection completed with this new technology, it is a huge responsibility for 3Scan to manage their data in a smart and sensitive format. 3Scan is able to collect more than 13 terabytes of data a day on each of the 12 different systems. They have a specialized infrastructure that is able to process and handle the amount of data collected. A specific way they have achieved data management is the process of building a server around each physical KESM instrument for quick data processing. The data can be transferred to a lab later for extensive processing.

“It’s always been a goal of ours to be a Contract Research Organization, or CRO,” comments Huffman, who originally was a biologist, “most labs aren’t set up to handle processes the way 3Scan is.”

“We run a company on a service basis, so we build and operate,” comments Todd Huffman (CEO). Instead of selling its Knife Edge Scanning Microscopes, 3Scan has chosen to run its business as an outsourced service. As a Contract Research Organization (CRO), they work with clients to slice and analyze their pathology samples. After running the sample through the KESM and processing the data with the software, a report is compiled sourcing from algorithms, and an onsite licensed clinical pathologist interprets the results. At this time, the company is primarily working on fundamental research with universities and pharmaceutical companies. The company is looking into getting FDA approval to apply their technology to clinical settings as well.

Undoubtedly, like other industries, the future of medicine will rely heavily on technology to improve care. Going forward, patients and doctors alike can expect higher accuracy and improved efficiency. However, like the KESM, the success of automated devices and digital imaging is dependent on the brains behind it. There are a host of pressures on the industry and the individuals involved. Both patients and doctors want to be sure they receive the right information, and that often requires more tests and higher costs. The services that 3Scan may soon provide could reduce these hurdles substantially.

“The KESM and what we’re able to do because of the KESM with Teledyne DALSA’s help is helping create a micron level applet of the human body, piece by piece. As personalized medicine becomes more important, precise diagnosis becomes more important, being able to have these spatially indexed points of information will help researchers and physician create better outcomes for patients,” said Huffman on looking to the future.

Written by Brad Finney, VP of Sales, North America and Noori Amin, Media Relations Specialist, Teledyne DALSA

Back to Enlightening Applications

Back to Enlightening Applications