Advances in Artificial Intelligence (AI) and deep learning have changed how quality inspection is employed in the manufacturing industry. AI-based systems bring a level of robustness and accuracy never achieved in the past with rule-based systems. And this is just the beginning of what we can accomplish using these newer image processing technologies. AI is well suited in applications where qualitative analysis is required, such as finding and identifying good and bad parts, sorting objects of different kinds, classifying defects by type, etc. In such cases AI will outperform the traditional techniques.

Today's powerful, innovative CMOS X-Ray detectors combine industry-leading performance with cutting-edge features for applications such as orthopedic and surgical radiology, mammography, intra- and extra-oral dental radiology, CT, and bone densitometry

A recent development by Teledyne DALSA X-Ray Solutions division's X-ray detector production & test facility is a new algorithm with the capability to identify a defect type (fibers) that could not be easily classified from other defect types using traditional algorithms. These fibers are particularly difficult to find because of their tiny and random nature. A fiber cannot be corrected using traditional flat field correction because the fiber may move between the scintillator and the silicon of a detector. Repairing a detector with a fiber is relatively simple. Therefore, finding a fiber before it moves and creates a blemish in the image for the end user is very valuable.

AI image analysis was used in this case, allowing for productivity, efficiency, and quality to be further improved by automation, in the form of stand-alone systems or as an assistant to the human.

Objective & Business Justification

This was a capability study on out of spec (OOS) defects on detectors with AI software, with fiber detection for the X-ray detector, as a first test vehicle and Teledyne DALSA Astrocyte as AI analysis tool. The primary objectives for this study included:

- Significantly reduce product selection time and make the process less product-engineer dependent

- Enable the difficult task of automating fiber detection

-

Once the capability is proven, this basis of AI software/concept can be used for:

- Similar, yet unknown OOS artefacts (anomaly detection)

- “Zero defects”; automatic inspection of defects during end inspection of detectors (missing screws, scratches, wrongly placed or missing labels etc.)

- PONC reduction (selection closer to the limits and automation of human interaction)

- Many more production improvements

Problem description

A fiber can be small, low in intensity deviation and hard to spot by visual inspection. As shown in Figure 1, a fiber is only 1 or 2 pixels wide.

Figure 1

Without AI a human-being needs to filter out fibers based on limits on length and intensity to comply with quality specifications of detectors. If these limits are set too tight, then a human will not be able to find the fibers. Also visually searching for fibers in a high-resolution image is time consuming and inefficient.

AI Model Development

The Teledyne DALSA Astrocyte AI training application was used to train an object detection model on a series of images each including a few fiber defects. Astrocyte‘s object detection is based on the YOLOX algorithm, one of the latest methods in object detection, to allow accurate finding of small objects. The usage of YOLOX was combined with the new “tiling” feature of Astrocyte allowing to perform training on large images (2976x2624) at native resolution without consuming too much memory. Processing images at native resolution is a mandatory requirement for locating tiny fibers. The tiling mechanism cuts the input image into small tiles (in this case 704x704) and process them one by one.

From the study we were able to achieve a mAP (mean Average Precision) of 0.935 with a very small image set of 85 images (from which 68 images were used for training and the rest for validation). In deep learning, mAP is the benchmark currently used to evaluate object detection algorithms. It covers tradeoffs between both precision and recall metrics into one score. Precision measures the percentage of your predictions that are correct, while recall measures your ability to identify the predictions, but is prone to false positives. mAP has a range of 0-1, so 0.935 is quite a good result!

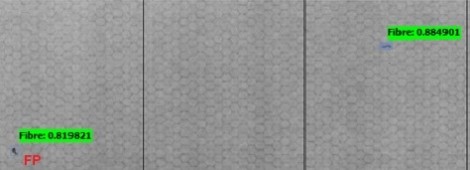

Figure 2: X-ray image with 2 fibers (left found by the AI only, upper right found by AI + Human eye)

Final Result

Teledyne DALSA X-Ray Solutions used a set of 85 X-ray detector images containing fibers from which 68 images were used for training and 17 images were used for validation only. After a thorough inspection of the images and the annotations, the object detection model found fibers that the human failed to spot. All fibers from the validation dataset were found correctly by the model plus three extra fibers that were missed by the human operator.

Conclusion

Although based on a limited data set, the conclusion can be drawn from the Teledyne DALSA X-Ray solutions capability study on out of spec (OOS) defects on detectors with the help of AI software that excellent results have been achieved and that tasks that are difficult to complete by humans and traditional algorithms, confidently can be shifted towards these kinds of machine learning models using Astrocyte with tiling and YOLOX. The goal to create a model that finds fibers, as well as performance close to selection by a human (and even slightly better) was reached, and the model that was built has proved to be far superior to any of the earlier methods of finding fibers. Astrocyte is a powerful yet easy to use application based on a fully graphical user interface. Astrocyte can yield quick and reliable results ready for deployment in production.

Written by Niels Markhorst, Developer of high-tech test systems, Teledyne DALSA

Back to Features

Back to Features