Camera Link, FireWire, and USB 2.0 have admirably served their intended purpose, but machine vision has changed dramatically since these standards were developed. While they all remain serviceable for some systems, for the most demanding applications, they have reached the end of the road. Consequently, GigE Vision, USB3 Vision and CoaXPress, are competing to take their place. Each one has its strengths and weaknesses but it is CoaXPress that will be the “likely winner”, as it has the ability to meet today’s most stringent requirements – all at lower cost per bit and with greater flexibility than the alternatives.

To defend this admittedly bold statement, it helps to start with a discussion of how the potential successors to Camera Link, USB 2.0 and FireWire are used and the unique demands placed on any potential vision system. In factories, for example, there is an ever-increasing need for faster and higher manufacturing throughput in factories. To achieve higher throughput, vision systems must capture very-high-resolution (uncompressed) images much faster while processing at a much greater speed.

In addition, image processing systems must be able to process a moving or still image and make a go/no-go decision within milliseconds of image capture. Advancements in complementary metal-oxide semiconductor (CMOS) image sensors are occurring rapidly and are now capable of much higher sensitivity and speed, dynamic range, and resolution. Image sensors which support 4K resolution are becoming common. In fact, at least one manufacturer is producing sensors with a resolution up to 250 megapixels. Consequently, the communications bus linking the camera to its processing resources must have significantly greater bandwidth and throughput, so Camera Link, USB 2.0 and FireWire simply won’t be fast enough.

These requirements aren’t limited to only traditional machine vision applications such as manufacturing and production either. For example, traffic and license plate monitoring and autonomous vehicles will require cameras that can produce extraordinary detail and color accuracy. Additional uses are medical imaging and telesurgery systems, which demand precise imaging with virtually no latency. Other challenging applications include video surveillance, aircraft infotainment, and high-speed board-to-board communications, as well as defense and aerospace systems.

All of these applications will push the boundaries further than ever before. To meet their requirements, higher bandwidths throughout the signal path up to 1200 MByte per second (MByte/s) will initially be needed with gradually increasing data rates in the future. Systems that require longer cable runs must be able handle these higher speeds with the least expensive cable and connector solutions as well.

The number of manufacturers of camera and frame-grabber equipment adopting CoaXPress continues to grow, as it offers them the easiest way to transition to high-speed digital imaging while minimizing deployment costs with speeds four times faster and ranges 10 times longer than competing solutions.

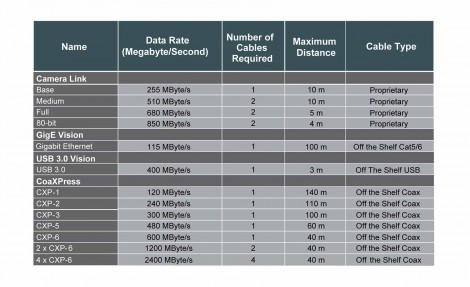

To be truly effective, a communications bus must combine simplicity (ideally plug-and-play), the capability for customization, the lowest possible cost per bit, as well as the ability to scale in performance with little or no additional hardware. Bearing all of this in mind, examining each candidate standard demonstrates their viability in these environments. They are compared in Table 1.

Next-generation machine vision bus standards compared

.

Camera Link

Camera Link is the mature standard; widely used, but bulky and expensive cables with limited cable lengths in the 4 to 10m range. Camera Link delivers data rates of 255 MByte/s (Base) to 850 MByte/s (80 bit), and some recent products support GenICam. Connectors cannot be installed in the field, a major issue in some environments.

Camera Link HS

Camera Link HS is the successor to the Camera Link standard and delivers data rates of 300 Mbyte/s with support for GenICam and scalability with the addition of cables. This gets expensive compared to standard off-the-shelf coaxial, or CAT5/6 or USB cable that can be purchased from your local retail outlet, and although it is possible to use coaxial cable, the best performance is obtained using somewhat-finicky CX-4 InfiniBand cables, at least for fixed scenarios. Connectors are also expensive and cannot be installed in the field, a major issue in many environments. Both the Camera Link HS interface and the CoaXPress are really aiming at the same marketplace, and many of the same advanced features can be found in both. However CoaXPress is being adopted by many manufacturers while Camera Link HS remains a niche solution and subsequent low adoption rate.

GigE Vision

GigE Vision delivers data rates up to 115 MByte/s using Cat 5 or Cat 6 cable. As it rides on the back of the ubiquitous Ethernet it can be part of an existing network of which there are millions throughout the world. It supports cable runs up to 100m and multi-camera applications, and enables triggering.

Finally, as in all image capture applications, uncompressed image files represent the highest possible resolution but are far greater in size. Therefore, because systems based on GigE Vision require that the image be compressed before sending it and later decompressed, this adds latency that is intolerable in some applications. GigE Visions is also capable of sending uncompressed data, however since it is only 115 MByte/s in bandwidth this presents a challenge.

USB3 Vision

USB3 Vision uses the USB 3.1 standard and has the advantage of universal use in many applications, not requiring a frame grabber card, and uses the GenICam programming interface. However, the lack of a frame grabber requires higher CPU usage. At 400 MByte/s its highest data rate is not much greater than that of base Camera Link, so full support for some current and probably all next-generation sensors is unlikely. And like all USB variants, cable lengths are extremely short – about 3 m.

CoaXPress

One of the newer machine vision standards in this mix, CoaXPress, has the advantage of being designed from its inception to be a successor to Camera Link by addressing all of its shortcomings, which it has achieved. For example, it is the only one of these four that allows video, camera control for triggering, and up to 13W of power to be delivered via a single, off-the-shelf 75-ohm coaxial cable up to 100m with standard BNC or DIN1.0/2.3 connectors. It is an asymmetric, high-speed, point-to-point open serial communication standard that is royalty-free and supports GenICam, with a roadmap that extends to 1200 MByte/s over a single cable.

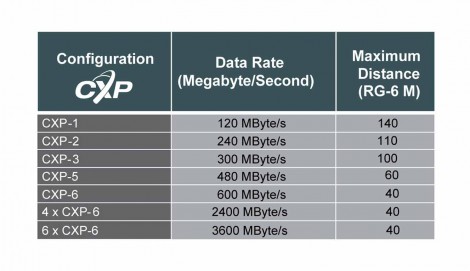

There is a misconception that CoaXPress can only be used in high-end applications. For lower end applications, CoaXPress sends uncompressed files which result is near zero latency. That may not be necessary in systems where the bandwidth requirement is less than 115 MByte/s, cable distance is less than 150m and no power over cable is required. In this case CoaXPress may not be needed. Even though coax cable is inexpensive, its shielding makes it more resistant to EMI than other types of cable and enables automatic cable-loss equalization to increase achievable distance. In addition, BNC and DIN1.0/2.3 connectors are easily field-installable. Maximum data rate over a single cable is 600 MByte/s, and scalability is essentially infinite, limited only by the number of cables that can be accommodated. For example, maximum range can still be maintained with a data rate to 2400 MByte/s when four cables are used. When simultaneously using additional cables for up to six lanes (Table 2) downlink speed of up to 3600 MByte/s is attainable over a distance of 40m with RG6 coaxial cable.

CoaXPress Configurations

The use of coax has other benefits as well. For example, as it is still used in many older analog systems making upgrades to higher-resolution digital cameras far easier and less expensive than the alternatives. In addition, there are hundreds of different variants of 75 Ohm cable designed to accommodate abuse, extensive flexing, resistance to chemicals and other contaminants, and other environmental factors. The cables also don’t suffer from skew that can be a factor with differential or multiple wires.

Although CoaXPress is designed to meet future imaging challenges its scalability works both ways, making it usable in the vast number of applications other than those considered to be “high end”. As a result, CoaXPress systems can be built using less- expensive components where the highest performance is not required, which is one of the reasons the standard is gaining popularity over a broad spectrum of applications and markets.

Contenders for the gold standard

Three of the contenders to become the “gold standard” for next-generation machine vision, GigE Vision, USB3 Vision, and CoaXPress have attributes that make them appealing in certain circumstances. However, for the majority of applications, CoaXPress has the broadest appeal. It was created from its inception to not only perform all of the functions that gave Camera Link its near-universal acceptance but also eliminates its weaknesses, while providing a cost-effective roadmap for satisfying tomorrow’s machine vision demands. As a result, of the competing standards, 600 MByte/s CoaXPress offers lowest cost, highest performance, and least power consumption.

Written by Zeph Freeman, Global Marketing Manager, Automotive Information Systems Division of Microchip Technology

Back to Blog

Back to Blog