The use of chemical vapour deposition (CVD) diamond as an engineering material in a growing number of highly demanding optical applications has been introduced in recent articles (ref 1).

Less attention has been paid to the reasons why CVD diamond has been the material of choice in these cases. Where do the wide ranging extreme properties of CVD diamond really pay off, both technically and economically, in optical applications?

Generally speaking, there are two ways to apply CVD diamond; as an integral part of an optical system, exploiting the properties of diamond to its full extent, or simply used to replace a traditional optical material only.

To understand this, one needs to examine the synthesis of CVD diamond and compare its properties with those of traditional optical engineering materials in various applications.

Synthetic diamond production methods

Synthetic diamond can be created in two ways. The first is by mimicking the process in the Earth’s mantle where diamond is formed under high pressure and high temperature conditions: HPHT diamond.

This material has excellent mechanical properties. However, due to defects and size limitations, it has not found its way into optical components or thermal management in electronics.

For such non-abrasive applications the, chemical vapour deposition (CVD) method has proven to be far more suitable. Element Six produces both single crystal diamond and polycrystalline diamond using plasma assisted CVD diamond (ref 2).

A plasma assisted CVD reactor used to produce diamond

(Source: Element Six)

The CVD method offers the ability to control the defect levels of diamond, allowing different grades of material to be produced and engineered to optimise pivotal properties such as optical absorption and thermal conductivity.

Manufacturing of products

Element Six has developed processes and equipment for laser cutting, lapping and polishing of diamond surfaces and metrology to determine and control the quality of the components.

By shaping the growth substrate poly-crystalline products can be manufactured into domes. For single crystal, special polishing methods have been developed to make smaller hemispherical lenses. These single crystal lenses are successful in immersion microscopy. (ref 3)

Material properties

Before looking at the exploitation of these properties in different applications, it makes sense to compare these properties of polycrystalline CVD diamond with several common optical and thermal materials (ref 4):

Comparison of properties of popular optical materials (Source: Element Six)

The combination of properties makes diamond the clear choice. For example, at an order of magnitude level the absorption of diamond may be somewhat higher than ZnSe, but the strength of diamond allows a 10 times thinner optic. The thermal conductivity difference of a factor of 100 on top allows a factor 10 higher power density to be used with CVD diamond optics.

Application areas of CVD diamond

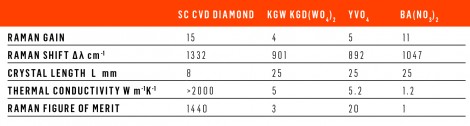

In the following examples, designs have been aimed at exploiting the combined properties of CVD diamond (see also table 1):

- Wide Transparency of CVD diamond (230-3000+ nm)

- Thermal conductivity (2000 W/m.K)

- Low CTE value (1 ppm/K)

- Mechanical strength (1050 GPa)

- Low losses (tanδ, Absorption)

Gyrotrons

One of the first applications of CVD diamond windows was as an exit window for high power Gyrotron devices used to heat up the plasma in nuclear fusion experiments (see top photo). CVD diamond windows have enabled the power level to reach 2 MW where the traditional material sapphire limited the power level to only 150 kW.

CO2 lasers and disc lasers

Another important application area of CVD diamond was in materials processing where it significantly increased output/unit time, reducing the cost of ownership for cutting and welding of sheet metal.

The most recent application of CVD diamond is in the driver laser and beam delivery system of Extreme Ultra Violet lithography equipment where 30 kW of CO2 laser power is used in the production 7 nm light for the production of the next generation of transistors.

In Disc lasers, the diamond allows excellent beam qualities at high power Yttrium Aluminium Garnet (YAG) based lasers due to a superb axial heat flux and high stiffness of the material (ref 1).

Raman lasers

A new application which is starting to gain a lot of attention is the use of diamond for Raman lasers.

Diamond has the largest Raman shift known of 1332 cm-1

(Source: Element Six)

Recent work by the University of Strathclyde (ref 5) has reported that Element Six high purity CVD diamond can produce broad ranges of wavelengths from a single solid state system, when used in conjunction with frequency doubling and tuneable semiconductor sources. Macquarie University has shown that the use of diamond greatly enhances the brightness of the pump laser as well as an improvement in M2 from pump to Raman beam of a factor 2.7. (ref 6)

System enabling benefits of diamond over alternatives

In general, the cost of diamond optics in comparison to sapphire and ZnSe-based optics is 7 to 10 times higher. For some applications, at first glance the limited performance improvement of diamond versus cost doesn’t add up – until one considers the benefits in more detail.

- Due to their exceptional thermal properties, diamond optics do not suffer from thermal lensing, so no compensational correction system is required

- The chemical inertness of diamond optics means they do not degrade in oxidizing or reducing environments

- The benefits derived from the high thermal conductivity and robustness of diamond include:

- No or very low maintenance cost

- Increased “up-time” compared to other optics, especially important in 24/7 operation

- Long life time, no wear so no replacement required

- Constant beam quality independent of time of operation at higher powers for high throughput

This demonstrable lower cost of ownership along with improved performance benefits explains why diamond is established as the material of choice in demanding optical applications.

Written by Henk de Wit, Business Manager Optical at Element Six, a de Beers Group company.

References:

Ref 1: R. S. Balmer, J. R. Brandon, S. L. Clewes, H. K. Dhillon, J. M. Dodson, I. Friel, P. N. Inglis, T. D. Madgwick, M. L. Markham, T. P. Mollart, N. Perkins, G. A. Scarsbrook, D. J. Twitchen, A. J. Whitehead, J. J. Wilman and S. M. Woollard, Chemical vapour deposition synthetic diamond: materials, technology and applications, Journal of Physics: Condensed Matter (2009)

Ref 2: A. Bennett, Optik & Photonic 4/2014, 49 - 52, Wiley-VCH Verlag GmbH & Co, Weinheim

Ref 3: H. de Wit, Bearbeitung von Diamantoptiken fuer Hochleistungs laser, Photonik 01/2015,

Ref 4: T. Mollart, the Element Six CVD Diamond handbook, www.E6.com

Ref 5: Parrotta, Daniele C; Kemp, A; Dawson, M; Hastie, J, Multiwatt, continuous-wave, tunable diamond Raman laser with intracavity frequency-doubling to the visible region., IEEE Journal of Selected Topics in Quantum Electronics, Vol. 19, No. 4, (2013)

Ref 6: R. P. Mildren, A. McKay, R. J. Williams, O. Kitzler: Diamond Raman Lasers, Optics and Photonics News (2014), 44 - 49

Back to Features

Back to Features