Widely used over the past two decades in the aerospace and military industries for remote sensing applications, hyperspectral imaging systems are now finding a home on production lines at food producers where they are being deployed to inspect produce and other food items.

Hyperspectral imaging systems have an advantage over traditional machine vision systems because they integrate both conventional imaging and spectroscopic techniques. This enables them to simultaneously capture both spatial and spectral information about a product across a large range of spectral bands. As a result, they can be used to nondestructively determine the morphology of produce while simultaneously measuring its chemical composition.

According to Dr. Aoife Gowen, a Senior Lecturer at the School of Biosystems Engineering, University College Dublin, hyperspectral imaging systems are similar to other optical measurement techniques in as much as they can operate in reflectance, transmission or transflectance modes. The choice of which mode to use depends greatly on the characteristics of the food sample to be analyzed.

Imaging beneath the surface

In the food industry, the quality of produce such as fruit is often judged by its surface characteristics. Because of that fact, reflectance imaging systems can be used to examine produce for both surface and subsurface defects such as bruises.

Transmission imaging, on the other hand, enables the internal defects in produce to be identified. Such hyperspectral transmission systems have been used to detect parasites in fish, which have distinct spectral characteristics compared with that of the flesh of the fish itself.

In some cases, however, where a food may absorb, or scatter, an inordinate amount of light from an illumination source, it may be impractical to use a transmission imaging system. One alternative is to use a transflectance imaging system that captures light partially transmitted through the produce. Such systems have been used to obtain spectra from the interior of heterogeneous food samples such as thick cuts of entrecote beef to determine their fat content.

University College Dublin’s Dr. Gowen says that by far the most popular type of hyperspectral imaging systems adopted in the food industry use imagers that capture light in the visible very near infrared (IR) range between 400nm to 1000 nm. Not only are the CCD detectors that operate in this wavelength range relatively inexpensive, they are effective at imaging many common food defects, such as color changes, water content, surface bruising or fecal contamination.

QualySense’s QSorter takes a high-resolution colour image of grain from which it can identify defects. A near-IR sensor is also used to define how much protein or moisture content is in the grain. The seeds are then classified and sorted.

To detect wavelengths in the higher full near-IR spectrum range, hyperspectral imaging systems commonly use InGaAs detectors, rather than the CCD detectors deployed in visible very near IR systems. Although such detectors can be ten times more expensive than their CCD counterparts, full near-IR hyperspectral imaging systems operating in the 800 nm to 2500 nm wavelength range can determine the fat, or protein content, within foodstuffs such as meat or poultry.

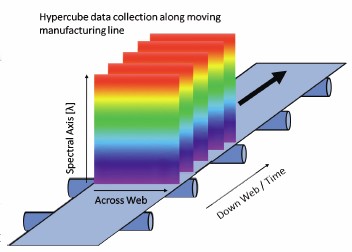

The most prevalent type of hyperspectral imaging system at use in food processing plants is the push broom scanner.

As the produce moves beneath the scanner, the push broom camera gathers a complete spectrum of each point along one spatial line. Successive lines on the sample measured over time form a complete hyperspectral dataset called a “hypercube” that contains information in two spatial dimensions and one spectral dimension. (Courtesy of Middleton Research).

Three types of systems can be used to capture hyperspectral images: whiskbroom scanners, filtered cameras or push broom scanners. However, the most prevalent type of hyperspectral imaging system at use in food processing plants is the push broom scanner. Its advantage is that it can be mounted over a conveyor based systems to inspect produce as it moves under the scanner at a constant speed.

In a reflectance imaging system, for example, a push broom scanner may be mounted perpendicular to the movement of the produce along the conveyor line. As the produce moves beneath the scanner, the imager inside the camera gathers a complete spectrum of each point of the produce along one spatial line. Successive lines on the produce measured over time form a complete hyperspectral dataset called a “hypercube” that contains information in two spatial dimensions and one spectral dimension.

Key characteristics of a hyperspectral imaging system

The two key characteristics of any hyperspectral imaging system are its spatial and spectral resolution. The spatial resolution determines the size of the smallest object that can be detected on the surface of the produce, while its spectral resolution is a measure of its ability to resolve spectral features, which might represent the amount of fat or water present -- into their separate components.

Hyperspectral imaging systems that can resolve features in food products down to around 1mm may be perfectly adequate to identify bruises on food such as apples or fecal matter on poultry products. However, with some minor contaminants smaller than 0.5mm -- such as moulds that are beginning to grow on the surface of produce -- the contaminant may be smaller than the spatial resolution of the system, making it impossible to identify.

Like spatial resolution, the spectral resolution of a hyperspectral imaging system is a key factor that determines which chemical characteristics of produce can be identified. If the spectral resolution of the system is too low, it may be impossible to characterize the presence of chemicals in the produce. On the other hand, if the spectral resolution is higher than necessary, then the time taken to capture the hyperspectral data may be longer than is commercially viable.

Many commercial systems in the food industry offer spectral resolutions between 5 to 7nm. This is adequate to enable them to determine the fat or water content of produce from the spectral signatures obtained by the hyperspectral imaging system at acceptable production line speeds. When developing any new hyperspectral system, tradeoffs must be made between the number of bands of wavelengths captured, how accurately those wavelength bands need to be resolved, and the speed of the inspection process itself. Dr. Gowen says that one tradeoff that could be made to enhance the speed of an inspection process, for example, would be to limit the number of spectral bands captured and/or to lower the spectral resolution of those bands. Such tradeoffs, of course, are highly dependent on the nature of the produce and the defects to be detected.

Insort's Sherlock Separator system.

Having collected the data from a sample, a hyperspectral imaging system must process the spectral and spatial data in the hypercube to deliver meaningful results that can be used to control a system further down the production line to accept or reject the food products.

To enable the system to do so, system designers must first build a calibration set of data from a set of images captured from both acceptable and unacceptable produce. The software approach for the identification tasks can then be chosen and its effectiveness determined by presenting the system with an independent validation set of produce.

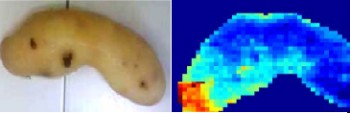

The Sherlock Separator system scans potatoes in the near infra red. The spectral information obtained contains details which allows the system to analyze the chemical composition of each potato, enabling it to identify, and then to reject, potatoes with so-called “sugar-end defects”.

The amount of data generated by a hyperspectral imaging system can be considerably greater than those generated by machine vision systems. Hence, specialized, and often proprietary, algorithms are often used to compare the spectral and spatial characteristics of the acquired images with the data set. According to Dr. Gowen, these range in complexity from those that compare the differences between the magnitudes of a few spectral bands to more sophisticated techniques that analyze the differences between the acquired data and the data sets using fuzzy logic, support vector machines or neural networks.

Needless to say, the plethora of processing options open to a system designer mean that careful consideration must be made at the outset as to the acceptable tolerances of the system that will be acceptable by the food manufacturer. While an expensive, sophisticated processing model may well be able classify 100%of the defects in a specific food, if the food processor is content with less accuracy, a simpler processing model may suffice.

Lastly, it must not be forgotten that the integration of any system into a production line can be a challenge, and this is no less true in the case of hyperspectral imaging systems. To ensure the effectiveness of such systems, system integrators must ensure that they have considered the nature of the environment into which the system is to be installed, paying careful attention to the impact of any external light sources and changes in ambient temperature.

Written by Dave Wilson, Senior Editor, Novus Light Technologies Today

Back to Features

Back to Features