Hyperspectral imaging combines infrared spectroscopy with machine vision to produce images which can be colour coded according to the chemical composition of the objects being imaged. Its ability to identify differences in the chemical composition of organic materials opens up major new possibilities for detecting impurities in food products. Most importantly, because affordable systems are available that operate in real time, they can also be used on high speed production lines for food processing and packaging inspection.

Organic materials selectively absorb light at different wavelengths in the infrared region of the spectrum depending on their composition. This gives them distinctive ‘fingerprints’ which can be used to uniquely identify them. Chemical colour imaging produces images where each pixel is colour coded according to the chemical composition of the material at that point. The resulting colour images can be processed and analysed using standard machine vision tools. Typical applications for hyperspectral imaging in the food processing industry include:

- Finding foreign materials (e.g. plastic pieces or insects in products)

- Measuring product quality (e.g. concentration of sugar, homogeneity)

- Controlling different production stages (e.g. before and after baking, mixing)

Typical applications in the food packaging industry include:

- Seal inspection (for contamination)

- Product uniformity

- Quality assurance through the packaging material

Food sorting applications

By ‘tuning into’ just a few key wavelengths that would distinguish between specific materials or identify known contaminants, hyperspectral imaging can provide a robust and reliable method of foreign body detection in foodstuffs. The ability to discriminate on the basis of chemical composition is essential in many applications. For example when sorting nuts such as almonds, kernel and shell fragments cannot be sorted on the basis of size colour or shape. In addition, impurities such as pieces of wood, or mould or rot on nuts cannot be identified very easily using traditional imaging methods. Other similar sorting applications include:

- Grains and seeds

- Frozen vegetables (removing foreign objects before packaging)

- Dried food (for example dried mushrooms can look similar to wood shavings)

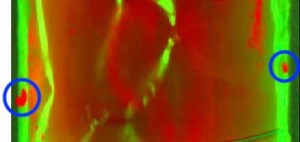

- Meat (to distinguish between fat, bone and gristle) – see image

Hyperspectral imaging of meat allowing regions of fat bone and gristle to be identified (Courtesy Perception Park)

Potatoes can have many diseases that are not directly visible with colour cameras. One example is ‘sugar end defect’ which is based on the relationship between sugar, starch and moisture. This defect can cause brown streaks in fries when they are cooked. A food processor might only allow 2% of this defect before looking for another supplier, so it is very important for suppliers to be able to identify it. One way of avoiding the possibility of delivering potatoes with this defect is to cut the ends off before delivery. This means that suppliers have a lot of waste material, reducing profit margins. However using hyperspectral imaging to identify this defect can allow the potoatoes to be sorted before dispatch.

Automated sorting

Foreign body contamination is recognised as one of the most common reasons for food product recalls. Automated sorting of food products from a conveyor belt is possible using hyperspectral imaging as an impurity detector. In this case, contaminants identified by the technique are automatically removed by jets of compressed air. Consideration must be given to the set up for the system. Non-organic contaminants such as glass and metals do not absorb NIR radiation. However, if the system is configured with a ‘totally black’ background, there is sufficient diffuse reflectance from these materials to produce a measurable signal. This is often most easily achieved by using a free-fall arrangement where the material to be inspected drops in front of the camera. The impurity detector could be set up in two ways. In the first, the ‘good’ material is identified and everything else is classed as a contaminant and is rejected. However, compressed air is an expensive consumable. If it is possible to differentiate ‘hazardous’ and ‘non-hazardous’ impurities on the basis of their spectra, the filter could then be set for ‘good material’, non-hazardous impurities’ and ‘hazardous impurities’. For non-hazardous impurities, short precise shots of air can be used on the impurity. This reduces compressed air consumption, and keeps over sorting at a low level. Even if an impurity is missed, there is no danger that the impurity will harm the end-customer. For hazardous impurities, longer air shots from more reject nozzles are used on the impurity to make sure that it is removed. This uses more compressed air and can result in over-sorting, but expensive product recalls are avoided.

Hyperspectral imaging technology

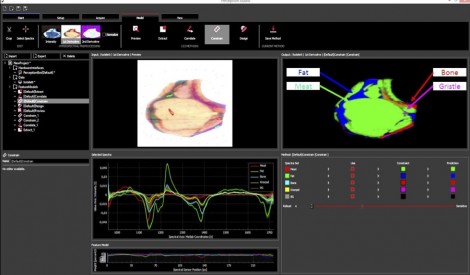

A spectrograph is needed to sort the light reflected from the sample into its constituent wavelengths. An IR-sensitive sensor then acquires an image from the sample at each of these wavelengths. These images are combined to form a three-dimensional hyperspectral data cube which can contain very large volumes of data. The CVS Hyperinspect system from STEMMER IMAGING has all of these necessary components built into a fully functional system to meet the particular requirements of the application. The system also includes flexible, high-speed data processing software to extract data from the data cube and produce the colour coded image. Images can be further processed and analysed using the powerful machine vision software that is also included.

Food packaging inspection

A report by WRAP (Waste and Resources Action Programme) has estimated that up to 480,000 tonnes of food is wasted in the UK each year because of poor seals in packaging.

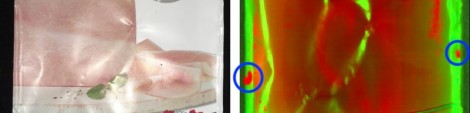

Hyperspectral imaging of sliced ham pack shows pieces of ham trapped in the seal (Courtesy Perception Park)

One cause of this is food trapped in seals. For example, when sliced cheese or meat is packed, small pieces can become trapped in the seal causing leaks where air, fungal spores or bacteria can contaminate the product. Hyperspectral imaging allows defects such as these to be found even if the packaging is overprinted, since many packaging materials are transparent to the infrared light used in the technique. The image shows part of a sealed pack containing ham. The packaging appears green in the hyperspectral image and the ham appears red. Pieces of ham trapped in the seal can be clearly identified. This cannot be detected using conventional colour imaging.

Written by Mark Williamson, Stemmer Imaging

Back to Features

Back to Features