Following many years of use in aircraft, head-up displays (HUDs) were first introduced to cars by General Motors in 1988 and are now offered, usually as an extra-cost option, by several major vehicle manufacturers. They project a virtual image onto the windshield and it is widely recognised that this enhances safety by proving vital data whilst the driver continues to view the road ahead.

Since their introduction, they have undergone several technological changes and one of the latest innovations involves the use of MEMS (micro-electromechanical system) technology. Based on techniques developed by the microelectronics industry, MEMS has been outstandingly successful in producing miniaturised, rugged and often inexpensive devices such as silicon sensors, print heads, microphones, gyroscopes and resonators. Automotive HUD systems are now being developed which exploit the capabilities of MEMS technology.

Three-laser system

Today’s automotive HUDs are based on several different principles such as liquid crystal display-thin film transistor (LCD-

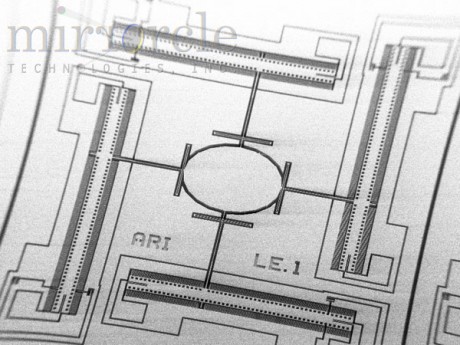

Using a beam splitter or other optics, this beam is directed onto the MEMS device. This is the heart of the system and comprises a microengineered 2-D micromirror (Figure 1) that scans the beam in a raster pattern. The projected image is created by modulating the three lasers synchronously with the position of the scanned beam. The silicon mirrors are small, typically around 1 mm in diameter, and are coated with a thin, highly reflective metal film of aluminium or silver with a reflectance of around 80-90 percent or more. They can be actuated in several ways, including electrostatic, the most widely used, and electromagnetic methods and because of single-crystal silicon’s excellent elastic properties and freedom from fatigue, they can be actuated at frequencies of up to 50 kHz.

Figure 1. Image showing a 2-D micromirror (centre)

Figure 1. Image showing a 2-D micromirror (centre)

(Credit: Mirrorcle Technologies, Inc.)

As yet, only a few companies are involved with this technology. One is MicroVision, which uses a patented MEMS scanner as the core of its PicoP display technology. In the case of a HUD, proprietary optical elements direct the beam of light toward optics external to the PicoP display engine that ensure that the image is visible within the driver’s field of view. Pixels are created by a repetitive horizontal scanning motion that rapidly sweeps the light beam to place the pixels into rows and a vertical scanning motion that moves the light beam up and down to points where successive rows of pixels are drawn. This process continues until a full image appears. Because this happens so rapidly, the image appears to be static. The complete projection engine, also known as the Integrated Photonics Module, is just seven mm in height and has a total volume of less than five cubic cm. MicroVision’s display technology is just entering the HUD market, with the first volume product appearing this year in the “Cyber Navi” system from Pioneer, aimed at the Japanese car market.

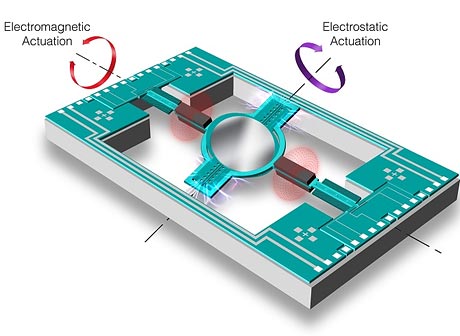

Another company hoping to capitalise on the automotive HUD market is Maradin. Based in Israel and founded in 2007, the company has developed a similar technology which is based on a 2-D gimbaled micromirror (Figure 2) that uses a combination of electromagnetic and electrostatic actuation techniques to deflect laser beams at scanning angles of up to 32° at high speeds in both axes. This and an analogue and digital ASIC driver chip are integrated in a single package with dimensions of 5 x 15 x 4.3 mm. In addition to HUDs, the technology is well suited to applications in consumer mobile devices such as pico-projectors.

Figure 2. Schematic of Maradin’s 2-D MEMS scanning micromirror chip. (Image by Maradin Ltd.)

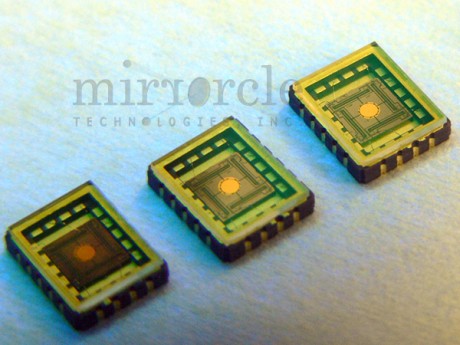

A further company that has commercialised MEMS micromirror technology is Mirrorcle Technologies, Inc. Based in California and founded in 2005, this company produces a family of 2D scanning micromirror devices (Figure 3) based on MEMS fabrication technology which arose from research at the Adriatic Research Institute (“ARI”) in Berkeley. Earlier this year, Mirrorcle demonstrated its technology at the Consumer Electronics Association (CES) trade show in Las Vegas. Using the patented emissive projection display (EPD) foils produced by Sun Innovations, which are able to transform scanning laser beams into a bright, fluorescent display of high-visibility “screen” images, the company used its devices to project a variety of vector graphics onto a car windshield treated with these foils, thus demonstrating its ability to address the automotive HUD market.

Figure 3. Packaged micromirror devices

(Credit: Mirrorcle Technologies, Inc.)

Growth in HUD market

All indications are that the use of automotive HUDs will grow considerably over the next few years, reflecting several factors: technological developments, falling system prices allowing these products to migrate from the luxury sector down the product chain and growing safety awareness among drivers. According to an analysis by TechNavio (“Global Automotive Head-up Display Market 2012-2016"), the global automotive HUD market will grow at a CAGR of 28.61% over the period 2012-2016.

Whether MEMS technology will play a central role during this period of growth in uncertain; Denso, for example, is promoting a different technology involving an image reflected from an LCD and other companies are working on holographic techniques. However, when sensors first started to appear in cars, many were based on electromechanical technologies but MEMS sensors soon proved their worth and now dominate many applications in engine management and safety systems. Although MEMS-based HUD systems differ from these in that the MEMS component is only part of the overall system, there are reasons to be optimistic: MicroVision maintains that this technology scores over many alternatives as the brightness and contrast is better, allowing viewing in bright daylight and the colour saturation and overall image quality is better, too. All of these are critical considerations being addressed by the automotive HUD manufacturers and if MEMS can establish a competitive edge over the other technologies, its future should indeed look bright.

Written by Rob Bogue, Contributing Editor, Novus Light Technologies Today

Back to Features

Back to Features