The Fraunhofer Institute for Laser Technology (ILT) has developed a new optics system for the manufacture of periodic microstructures. This system increases processing speed when working with ultra-short-pulse (USP) lasers to many times the speed of conventional systems. By splitting the laser beam into several “beamlets,” the output of high-power USP lasers can be fully utilised for micro-processing, reducing process costs. At the 2nd USP Workshop, which will take place in Aachen, Germany on 17-18 April 2013, Fraunhofer ILT will present the process underlying this development and speak on the “SmartSurf” project to minimise friction in components that are subject to high tribological stresses by means of functional surfaces. (According to Wikipedia, “tribology” is the science and engineering of interacting surfaces in relative motion; it includes the study and application of the principles of friction, lubrication and wear.)

Whether for manufacturing masks and micro-sieves or creating functional surfaces for components or stamping tools that are subject to high tribological stresses, more and more applications require a micro-structured surface and require it over increasingly larger areas. The fabrication of micrometer-scale structures calls for precise processing of the work pieces and the USP laser is suitable for this purpose. Alongside mechanical processes, nanosecond lasers are the current choice for this type of work with their greater cost-efficiency making them more well-established than USP lasers. However, in nanosecond processing, beading occurs as a result of melting effects, which means that the work piece often needs extensive post-processing. In addition, the melting effects limit the resolution of the micro-structuring.

In contrast, functional surface structures can be created with USP lasers such that no post-processing is required. Due to the strong localisation of the laser energy applied to the work piece and the high beam intensities, no beading occurs during processing. Furthermore, processing with a USP laser delivers high precision within a tolerance range of just a few micrometers, as well as high depth resolution in the region of 100 nanometres (nm). However, ablation rates are relatively low, meaning that processing times can be long compared with those of pulsed lasers operating in the nanosecond range. For now, therefore, micro-structuring with USP lasers is only attractive from an economic perspective for high-end products or tools for mass replication. Moreover, in many micro-structuring applications, only a fraction of the available laser output can be used with the USP laser systems in the power range of 50 watts (W) to 100W. This power range is commonly used in industry today because only a limited maximum power can be applied to each processing point. Injecting too much power into a processing point, especially with small focus diameters in the micrometer range, leads to plasma formation and thermal effects, as well as beading caused by melting. The result is poor processing.

Researchers at Fraunhofer ILT have now addressed the question as to how optimum use can be made of high laser power for USP micro-structuring while ensuring suitable processing results. High-speed beam deflection is one option for fully utilising the available laser power for USP micro-structuring. To ensure high ablation quality with this method, the pulse energy is kept low. However, a high surface rate is obtained by virtue of a high pulse frequency coupled with a high scan speed. With a polygon scanner system developed at Fraunhofer ILT, it is possible to reach scan speeds of up to 350 metres per second (m/s). This enables high-frequency laser pulses to be rapidly distributed onto large surfaces.

Another option currently being pursued at Fraunhofer ILT is the parallelisation of laser ablation. By splitting the laser beam into several beamlets, significantly greater laser power can be utilised. This beam splitting is made possible by a diffractive optical element (DOE). The DOE consists of an array of microstructures, which are capable of producing virtually any type of intensity distribution behind the element by means of diffraction depending on the design. The research team at Fraunhofer ILT fitted the DOE between the beam source and a galvanometer scanner in such a way that the split laser beams are imaged in the galvanometer scanner. Focusing the beams using an f-theta lens eventually produces a periodic array of processing points, which can then be moved over the work piece. This makes it possible to ablate patterns of any complexity.

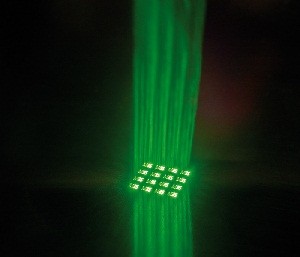

The splitting of a laser beam into 16 beamlets has already been successfully demonstrated at Fraunhofer ILT. This beam parallelisation enables the work piece to be processed at 16 periodically arranged points simultaneously, resulting in a 16-fold increase in processing speed. In a laboratory experiment, Fraunhofer ILT has already successfully tested processing with 144 beamlets and further scaling is possible.

In the future, this technology will permit the output reserves of current high-power USP laser systems to be fully utilised on the work piece for laser processing. Processing times will drop accordingly, leading to a significant reduction in overall process costs. This will make USP lasers significantly more attractive to users from an economic point of view for manufacturing periodic microstructures. With this approach, it becomes economically feasible to structure even large surfaces. Based on this technology, Fraunhofer ILT has developed a prototype machine for producing microstructures with USP lasers, which is to be further developed in future projects to make it suitable for industrial applications. The long-term goal is to use multi-hundred-watt lasers for micro-structuring before too long.

Photo: USP parallel processing with multi-beam technology © Fraunhofer ILT, Aachen/Volker Lannert.

Back to News

Back to News