Multicopter drones are unmanned aircraft that employ multiple rotors for lift and propulsion, rather than a single large rotor like a traditional helicopter. Multicopters are highly agile, capable of aggressive maneuvers, hovering, and rapid changes in direction by varying the speed of their individual rotors. Nimble maneuvering has made multicopters popular for aerial photography, infrastructure inspection, surveying, agriculture, and search and rescue operations.

Multicopters vibrate while flying, just like any other drone. In excess, vibrations will degrade multicopter stability and can result in shortened flight times, early component deterioration, and other negative outcomes.

To better understand vibration distribution during flight, engineers at Hiroshima University (Hiroshima, Japan) have proposed a model-tracking 3D-DIC vibration measurement method using two Mikrotron EoSens 2.0CXP 2 cameras to visualize a hovering multicopter from the ground. Applying Digital Image Correlation (DIC) to the camera's 500 frames-per-second stereo 1920 x 1080 pixel images, the engineers achieved precise 3D vibration analysis based on thousands of tracked measurement points. Identifying areas of heavy vibrations while the multicopter is in-flight can detect potential structural anomalies requiring maintenance or repair.

Experimental Setup

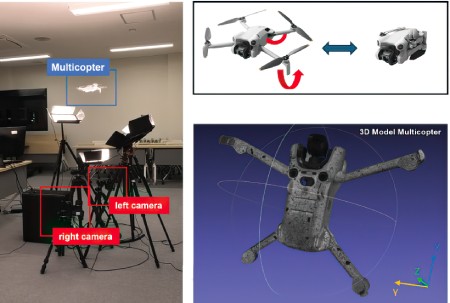

For testing, the engineers from Hiroshima University used a DJI Mini 4 Pro quadcopter. Its surface was painted with a random pattern, and twelve black-and-white markers were affixed to the body to allow frame-by-frame model tracking.

During testing the research team had the quadcopter hover 2 meters above the lab floor, its rotors turning at approximately 100 rotations-per-second. Two Mikrotron EoSens 2.0CXP2 cameras equipped with 50mm lenses were positioned on the ground surrounded by LED lights. Stereo 8-bit RGB images of 1920 x 1080 pixels were captured with 1.0 ms exposure time for 10 seconds at 500 fps. Images were transmitted from the Mikrotron cameras to a PC via a CXP-12 quad frame grabber. The PC performing the processing was equipped with an Intel Core i9-13900K 3.00 GHz CPU, NVIDIA GeForce RTX 2080 Ti, and Windows 11 Professional 64-bit OS.

Highly detailed 3D point clouds digitally representing the quadcopter's surface were generated using a ZEISS 3D scanner measuring 953038 points. Each cloud was then resampled to reduce the number of measurement points to 3518 points for the 3D software sensor. This step permitted the visualizing of frequency-domain 3D images up to 250 Hz.

Color mapping of the 3D images clearly identified local areas of the quadcopter that were vibrating and the area's frequency intensities. Frequency (Hz) refers to the vibration cycles per second or how fast the vibration occurs, while intensity described the amplitude or the strength of the vibration.

Model-tracking 3D-DIC vibration measurement setup (photo courtesy of Hiroshima University)

Conclusion

Using a hovering multicopter and two Mikrotron cameras, Hiroshima University engineers were able to validate their 3D-DIC vibration measurement method in isolating local vibration frequencies and intensities that are crucial for flight stability, safety, and reliability. Unlike accelerometers or strain gauges, the 3D-IDC method does not face limitations due to restricted attachment points. Additionally, since it is non-contact, flying performance won't be impacted.

Moving forward, the engineers plan to enhance their system to yield deeper insights into flight dynamics and structural behavior.

T. Ogata, F. Wang, K. Shimasaki and I. Ishii, "Model-Tracking-Based 3D Vibration Distribution Measurement of a Hovering Multicopter Using Stereo HFR Cameras," in IEEE Access, vol. 13, pp. 159028-159036, 2025

Back to News

Back to News