Semiconductor lasers are revolutionizing our lives in the 21st Century. They are critical components in data communications; additive manufacturing, including metal and plastic printing; lidar; and optical sensing – the fastest growing technology markets in the world right now.

Vector Photonics’, a spin-out from one of the world’s leading academic groups in photonics at the University of Glasgow, has invented PCSELs, a proprietary technology that is the first, major breakthrough in semiconductor lasers for 30 years.

PCSELs: Low cost with high speed and power

PCSELs, short for photonic crystal surface-emitting lasers, deliver low cost with high speed (data) and power. All other current laser technologies offer only two of these three, key characteristics in one device.

VCSELs (vertical cavity surface emitting lasers) compromise power for low cost and high speed. EEL’s (Edge Emitting Lasers), including FP (Fabry-Perot) and DFB (distributed feedback) lasers offer speed and power, but are expensive to make.

PCSELs have other advantages, too. They emit light from the top surface, like VCSELs, making them easy to package and incorporate into PCBs and electronic assemblies. They are also made in a similar way to EELs, so existing, experienced, supply chain capability and capacity can be utilised.

In addition to this, PCSELs can be made at any wavelength to address a wide breadth of applications.

Laser technology evolution

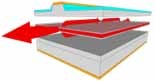

Fabry Perot lasers are the original laser technology. The laser feedback and emission are both in-plane, so light comes out of the end of the laser and the gain reflection is produced by a facet mirror. DFB lasers also have in-plane feedback and emission, but this time the gain region is produced with a grating structure.

VCSEL technology has out of plane gain and emission, where the light emits from the top surface of the laser. This makes both test and packaging of the lasers much cheaper than EELs (shown at right).

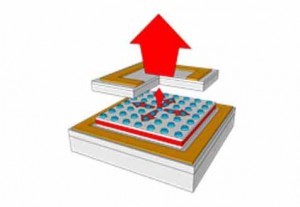

The PCSEL is a breakthrough. It is the only laser using in-plane feedback and out of plane, surface emission. Test and packaging remain cheaper, like VCSELs, but the PCSEL structure provides advantages in data rate, wavelength and power performance when compared to equivalent sized EELs or VCSELs.

VCSELs

A VCSEL is produced by having two Bragg stacks above and below the active region of the laser. The Bragg stack comprises layers of two materials of differing refractive index (n) ‘grown’ on top of one another. The number of layers, and therefore periods and the refractive index contrast (∂n), gives rise to the reflectivity. High number of periods gives high reflectivity, and high ∂n increases reflectivity per layer.

VCSELs have limited operational wavelengths due to the manufacturing challenges caused by the various material systems required for multi-wavelength operation. The VCSEL grating structure also has inherent limitations to the single mode, power levels that can be produced. So, although VCSELs can achieve high speeds and can be produced cost-effectively, their limited single mode performance makes them unsuitable for high-speed datacoms and long-distance telecoms. These limitations also restrict their use in sensing applications to relatively short distances.

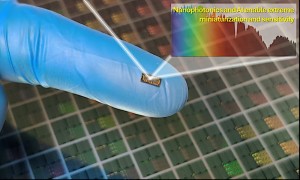

PCSELs

PCSELs use a 2D grating structure which scatters light linearly, in plane, and orthogonally, out of plane. Out of plane, orthogonal, surface emission offers huge cost and performance advantages for lasers and it makes them easy to package and incorporate into electronic assemblies. Out of plane emission is enabled and stabilised by the 2D grating structure (photonic crystal), creating feedback and single mode emission. This gives rise to some critical features of PCSELs, which are:

- Coherence and coherent arrays

- Solid-state array, beam steering

- High speed and data rates

- Wavelength flexibility

Coherence and coherent arrays

The in-plane feedback in PCSELs is two-dimensional, allowing coherently coupled arrays. The laser elements of the array are joined by a coupler region. This means the in plane light is linked between laser elements, creating coherence. Coherent light can be focused down to a small spot with greater light density, which has advantages in cutting, welding, melting, engraving and drying applications.

PCSELs offer high, coherent power, phase control enabling beam steering, high speed (high data) and low cost, all from a single platform – a revolution in semiconductor laser technology.

Due to the laser elements of the array being coupled in plane, in an ‘n x n’ array, power scaling is also enabled. High brightness and the unique geometry enable kilowatts of coherent power, which is simply not achievable with any of the other laser technology.

Solid-state array, beam steering

PCSELs have an array structure where the coupler region can be controlled in what is called an optical phased array. By electronically tuning the phase of the coupler region, the laser beam can be steered, in real time. This makes PCSELs immediately applicable to rapidly evolving LiDAR applications, where the beam is steered for imaging. High power, 3D printing in metal and plastic are other applications that could be revolutionised. As a solid-state solution, system size is reduced by 10x whilst reliability is increased.

High data rates

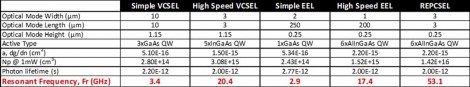

PCSELS are 2.5x faster than a VCSEL, the next best laser device, based on their resonant frequency. This permits multi-Gb modulation rates, with huge data speeds.

Wavelength flexibility

Semiconductor materials inherently emit different colours and therefore wavelengths of the light. The structure of PCSELs allows them to be made readily in any material to produce any colour or wavelength, yet they still retain all the advantages explained in this article.

Other laser types can only really be made in specific materials. For example, VCSELs have been demonstrated in high volume in GaAs at 850nm but are difficult to make in InP at 1310nm and 1550nm, so can’t be used reliably for high-speed datacomms.

Vector Photonics will continue to develop and improve manufacturing techniques and broaden its range of applications. The initial focus is on datacoms, but plastic and metal printing, lidar, optical coms, mobile consumer and sensing applications are close behind.

Written by Dr. Richard Taylor, CTO of Vector Photonics and inventor of PCSEL technology.

Back to Features

Back to Features