Conventional image processing systems have become established in automation in industrial applications in recent years. Machines that can "see“ can deliver more than systems without image processing, and this increasingly common knowledge among developers and designers. While conventional 2D and 3D vision systems check the quality of objects by recognizing certain error features on the surface, hyperspectral imaging (HSI) goes one step further: With the help of this technology, spectroscopic analysis of objects can be carried out in order to determine organic or inorganic impurities - not only on the surface, but also partly inside the inspected materials.

Hyperspectral imaging systems usually utilize 100 or more different wavelengths and a spectrograph that splits the light reflected from the object into its spectrum and reproduce it on the camera sensor. An HSI system assembles the resulting images into a three-dimensional hyperspectral data cube that can contain very large amounts of data. The result is a “chemical fingerprint” of the object under consideration, which enables the analyzed material properties to be determined precisely. With the help of special evaluation software, each identified chemical component can then be flagged with its own color in the images taken in order to visualize the existing substances in a simple way for the user. This technology is called Chemical Color Imaging (CCI).

"Hyperspectral imaging can be used in a wide variety of industrial application areas and in certain cases offers solutions for tasks where conventional image processing systems fail," explains Markus Burgstaller, Managing Director of the Graz-based company Perception Park that specialized in that innovative technology a few years ago. “In many application areas, it is necessary to classify substances that look very similar but are not chemically identical. HSI systems are able to analyze chemical properties and therefore recognize materials very reliably. With this technology, the concentration and distribution of ingredients can largely be recorded in real time.” These features of hyperspectral imaging systems make them particularly attractive for certain applications in the food industry.

HSI improving food security

Excluding consumer health risks is extremely important in any food production process: No contamination must remain undetected in the products. The food must also contain exactly the ingredients that the manufacturer wants to and that are defined in the product descriptions for the consumer.

HSI and CCI offer numerous application options for this industry. These technologies make it easier to find any contamination in food and identify unwanted objects such as stones or earth when sorting potatoes, carrots or other vegetables, as well as shell parts or other substances in the production of nuts, even in high-speed production lines. If food is stored for too long, maggots can also nest or fresh fruit can start to rot, according to Burgstaller: “In food production, the task very often not only means to detect any contamination, but also to identify rotten, immature or pest or mold infected goods. These and many other quality defects can be safely ruled out by the use of hyperspectral imaging systems."

Industrially manufactured food such as sausage and cheese are usually offered for sale in a shrink-wrap form. For those products, HSI systems allow quality checks through the packaging in many cases. A special task here is the inspection of heat-sealed joints, which are supposed to guarantee absolutely tight packaging of the food. Even the smallest contamination or damage to these sealed joints can lead to leaky packaging and spoilage of the goods before the calculated best before date. Unsellable products or expensive product recalls would then be possible consequences for manufacturers in this area, which can be avoided in many cases by using hyperspectral imaging.

HSI use cases in the food industry

Food processors around the world permanently try to improve their products for conformity as well as for identifying and removing impurities. For instance, producers of meats of all types need to know about the shares of meat, fat and bones in their products. With HSI technology, this can be done easily:

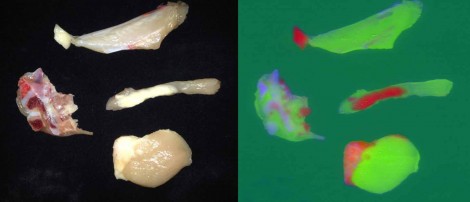

HSI chicken

While in the real picture on the left it is hardly possible to differentiate between the individual components of chicken parts, the meat (green), fat (red) and bone (blue) parts are clearly recognizable in the image on the right after a hyperspectral analysis.

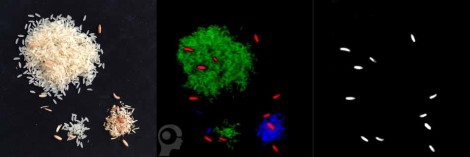

When producing rice or other basic food, you need to make sure to identify and sort out every single contamination such as maggots and pieces of wood between rice. An image processing solution based on hyperspectral imaging is capable of solving this problem:

HSI rice and wood maggots

In the original image on the left, rice, wood and maggots look very similar, but HSI and CCI identify each chemical component and flag it with own colors, as the image in the middle shows. The right partial image shows a segmentation image with recognized maggots.

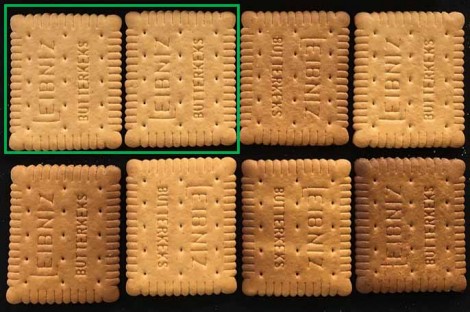

For international suppliers of biscuits that are producing in many different factories, it is a big challenge to provide the same quality in each plant all over the world. One quality feature is of course the color.

HSI biscuits

HSI technology allows for true color measurements and makes sure each biscuit meets the supplier´s color standard such as the two biscuits on the top left.

“There are many more than these three use cases in the food industry where HSI and CCI deliver economic and reliable solutions to check the chemical composition of goods and make sure no unwanted ingredients reach the end customer and endanger his health,” Burgstaller says. Perception Park´s software tools Perception STUDIO and Perception CORE enable to inspect chemical properties and to identify known and unknown impurities based on hyperspectral imaging, even for users with little knowledge in spectroscopy.

Experience hyperspectral technology live

On October 28 and 29, 2020, representatives of the manufacturing industry will have the opportunity to learn about the latest trends in hyperspectral imaging during the fourth Conference on Hyperspectral Imaging in Industry (chii) in Graz, Austria. The focus of this international industry meeting is the use and application of hyperspectral systems, which are presented in numerous short lectures by leading technology providers and in the context of an exhibition. Matchmaking meetings are also planned to answer individual questions.

Written by Peter Stiefenhöfer, owner of PS Marcom Services, Olching/Germany, on behalf of Perception Park

Back to Features

Back to Features