SiLC Technologies, a silicon-photonics-based provider of integrated 4D vision lidar solutions, has announced initial performance results for its integrated FMCW lidar test chip. SiLC's low-energy-consumption design leverages a coherent detection approach, similar to what is currently utilized in today's telecom systems. SiLC's initial data demonstrates a 112-m detection range with just 4.7 mW of optical peak power. This is very promising, given that traditional pulsed lidar systems operate at peak laser power levels in the hundreds, and even thousands, of watts. SiLC's early-stage performance test results were previewed earlier in the month at Photonics West.

Demonstrating the importance of eye-safe lidar, this year's CES served as a testing ground of another sort, as concerns around camera and eye-safe lidar emerged after a photographer's camera was reported to be damaged from a pulsed lidar. Though pulsed lidar is the most widely used in the industry, its maximum range is dictated by its peak laser power, resulting in bright flashes of laser light that have been shown to be more detrimental to sensors than the newer FMCW techniques. FMCW solutions transmit at more than three orders of magnitude less peak laser power than current pulsed lidar solutions while providing improved range, instantaneous velocity and multi-user interference-free operation. At peak power levels of around 100 mW, SiLC's lidar solutions will not be capable of damaging eyes, sensors or cameras.

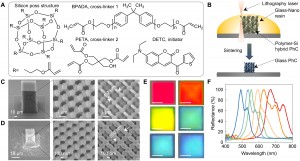

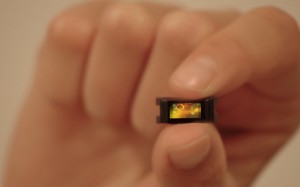

The FMCW chip design requires a fraction of the power typically required for lidar and is thus inherently more camera- and eye safe. A long-range FMCW lidar demands very high-performance levels from the optical components needed. The cost of these components has in turn limited commercial deployment of such systems. SiLC’s technology platform offers low loss, ultra-low phase noise, polarization independent operation, low back reflection and high optical power handling. In addition, SiLC's silicon photonics technology enables integration of all key optical functions into a small and low-cost silicon chip. SiLC utilizes silicon wafer fabrication processing technology, which enables complex electronics chips to be cost effectively mass manufactured for consumer applications to manufacture low cost and high-volume complex optical devices such as lidars.

The company says they are seeing significant market interest from automotive to augmented reality and biometrics. They believe this interest level will continue to rise as these industries increasingly depend on more sophisticated 3D vision systems.

Back to News

Back to News