System integrators faced with developing industrial vision systems must pay careful consideration to the correct choice of cameras, lighting, computer hardware and software. No less important, however, is the specification of the cable assemblies that tie together all the hardware components.

According to Ray Berst, the President of Components Express, choosing cabling and connectors traditionally involved thumbing through a variety of suppliers catalogs to find the most appropriate products for the purpose. However, as detailed as such catalogs may be, the selection task can still be arduous and prone to errors.

“Invariably, during the specification process, systems integrators have called upon the expertise of cable connector assembly suppliers to aid them in the selection process. After having described their requirements, the supplier could then select the components and cabling and prepare an engineering drawing which was then sent to the customer for approval. During such discussions, however, any miscommunication of ideas between the systems integrator and the supplier could lead to one or more revisions being made to the drawing, prior to any cable assembly being manufactured or dispatched,” said Mr. Berst.

To overcome this challenge, software engineers at Components Express have developed web-based tools called cable configurators that take the mundane work out of the selection process. These configurators can be used by trained personnel at the company’s distributors as they work with system integrators to define the types of cable and connector products required in the design of an industrial vision system.

“All of the cable configurators sport some fundamentally similar characteristics. They will all enable a customer to follow a series of steps to create a final cable assembly. By using one of the tools, a system integrator (or a distributor working with one) can select which style of connector that is preferred as well as the type of cable itself, the length and the interface speed. A specific product reference number is then configured by the software that can then be submitted to the company for a quote,” said Mr. Berst.

Targeting industry standards

To simplify the connector cable assembly process further, each of the software configurators has been developed to target a particular industry standard, such as CameraLink, Gigabit Ethernet, Firewire, USB and CoaXPress. In doing so, the company can take into account the unique technical aspects of each of the interfaces to ensure that the system integrator or OEM is not presented with a cable assembly that does not meet the requirements of the standard or build an assembly with an erroneous part number.

“The power of the configurator software is best demonstrated in the choice of a cable assembly for the CoaXPress interface, possibly one of the more complex camera to frame grabber interfaces. This is due to the fact that the proper cable type used in any CoaXPress system is actually determined by the interdependence of variables, notably, the selected connectors, their quantity and the desired speed of the CoaXPress system,” said Mr. Berst.

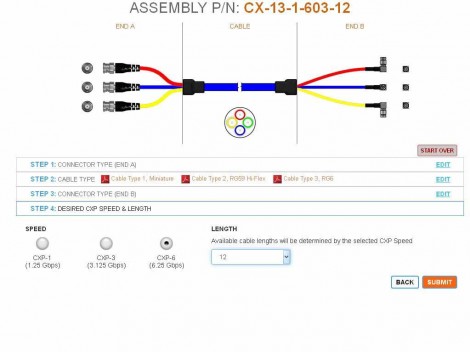

During the CoaXPress cable assembly selection process, the user is first presented with a pictorial representation and a brief description of the six possible connectors that can be chosen for one end of the cable assembly. Having chosen one of the six, the user is then prompted to enter the number of such connectors that are required in the system, where appropriate.

The configurator then prompts the user to specify the type and number of connectors that are required at the other end of the cable. To ensure that no erroneous entries can be made, any inappropriate choices are blanked out by the system. Finally, the speed of the interface and the length of the cable required are entered, after which a pictorial representation of the cable assembly and its associated part number is presented. The user can then choose to request a quote on the price of the cable assembly that is then forwarded onto Components Express’ network of worldwide distributors.

The power of the configurator software is best demonstrated in the choice of a cable assembly for the CoaXPress interface. This is due to the fact that the proper cable type that will be used in any CoaXpress system is actually determined by the interdependence of variables, notably, the selected connectors, their quantity and the desired speed of the CoaXPress system.

However, there are certain cable characteristics that the cable configurator does not allow the user to specify. These include the amount of flexibility of the cable, its chemical resistance or whether it is subject to out gassing. According to Mr. Berst, in such specialty cases, his company may be called upon to develop a product specifically for the application.

“In addition to simplifying the cable assembly selection process, the cable configurator also enables system integrators to download 3D models of any of the chosen connectors in either an IGES or STEP format. This enables them to import the models into their own mechanical engineering packages to determine whether the form and fit of the connectors will meet the mechanical tolerances that are required, removing the need to analyze the dimensions of the connector from a 2D image,” said Mr. Berst.

Choosing cable by specifying camera

Aside from providing tools to enable cable assemblies to be configured accurately and efficiently, engineers at Components Express are seeking to simplify the system integration task further by enabling the type of cable assembly specified to be made by simply choosing the type of camera that is used in the system.

By entering a section of the site dedicated to OEM Cables, developers can select camera types from their supplier. At present, there are three -- Allied Vision, JAI and Teledyne Dalsa, although more camera vendors will be added in the future. Having selected a particular model of camera, a user is then presented with a number of standard I/O cables that are suitable for use as well as links to data sheets highlighting their mechanical specification. In addition, the system also links to the cable configurator where developers can choose to configure a bespoke cable assembly should the need arise.

Future enhancements to selection process

Although the system has already eliminated much of the drudgery involved in specifying cable assemblies, Mr. Berst sees a future in which a systems integrator would be able to select not only the make and model number of a camera, but also the frame grabber or PC interface used in a system. The configurator would then display the number and type of cable and power supply assembly options that are available.

Nevertheless, the existing system has already had a profound effect on the cable assembly selection process. According to Mr. Berst, before the configurator was deployed, products returned to Components Express by its customers were due to a miscommunication between the company and a customer during the specification process. With the configurator in place, however, Mr. Berst now claims that the number of such errors has diminished significantly, reducing both the disruption to the system development process and saving time and money for the systems integrator.

Written by Dave Wilson, Senior Editor, Novus Light Technologies Today

Back to Features

Back to Features