Energy Independence and a move away from the use of coal has brought new interest in natural gas, but with it comes safety concerns about methane leakage. For companies to measure and disclose methane leakage, natural gas producers and distributors require new ways of detecting and measuring leaks in wellheads and aging pipeline infrastructure.

Reconciling these disparities will be crucial to the long-term success of natural gas. International Energy Agency (IEA) Executive Director Maria van der Hoeven has stated that the technology and knowledge already exist for unconventional gas to be produced in an environmentally acceptable way. But she cautions that if the social and environmental impacts are not addressed properly, there is a very real possibility that public opposition to drilling for shale gas and other types of unconventional gas will halt the revolution in its tracks. Other agencies have called for producers to collect and report emissions as a routine practice.

A variety of methods are currently available for detecting and measuring natural gas pipeline leaks ranging from manual inspection using gas-sniffing dogs to active sensing of absorption or scattering of gas molecules to passive monitoring using ground-, vehicular-,or even satellite-based thermal imaging. Each technique has advantages and disadvantages, but all require specialized equipment and expertise to implement and run. And these costs are amplified by the sheer volume of pipeline that must be monitored.

In 2011, there were 19,662 miles of gathering pipelines in the US originating at more than 460,000 wellheads, and nearly 2 million miles of main and individual service pipelines for distributing gas for commercial and residential use. It would be impractical to call for a full-scale replacement of this much pipeline. Rather, proactive monitoring of pipeline segments provides a more cost-effective way to identify which parts of the infrastructure are failing and initiate repairs to ensure public safety.

While modern spectral techniques have been developed that are capable of parts per billion sensitivities, these technologies have until recently been considered "hero experiments" that have not been scalable for use on a routine basis.

A simplified approach

In a recent report sponsored by the membership of the Pipeline Research Council International (PRCI) and led by Pacific Gas and Electric Company (PG&E), Picarro technology was vetted and tested in four regions in California, and Nevada: Diablo, Livermore, Sacramento, and southern Nevada. In side-by-side studies with legacy industry methods, Surveyor technology outperformed traditional methods, identifying significantly more leaks in considerably less time. According to the Diablo and Sacramento field reports, Picarro Surveyor located several leaks that legacy methods failed to find, including seven Grade 1 leaks (those requiring an immediate response) and ten Grade 2+ leaks (those requiring a scheduled priority repair within 90 days or less). Additionally, the new method indicated leaks up to 10 times faster than legacy survey methods.

CRDS uses a three-mirror cavity and a tunable, single-frequency diode laser to create a continuous laser wave.

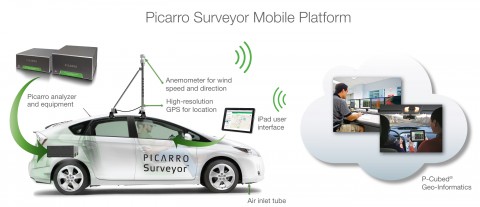

Making methane detection as easy as driving a car has required major scientific and technical advances so that natural gas producers and utility companies can turn accurate measurement of fugitive gas emissions or pipeline leaks into a routine practice. Picarro Surveyor uses a patented form of cavity-ring down spectroscopy (CRDS), which the company has implemented in a series of GHG instruments used by the world’s top atmospheric research institutions such as NASA, NOAA, LSCE, and the Chinese Meteorological Administration.

Surveyor in a mobile application enables detection of methane leaks from pipes under road surfaces

As with other forms of spectroscopy, CRDS measures the near-infrared absorption spectrum to determine what small gas-phase molecules maybe present in the air and in what concentration. Most conventional IR, however, lacks the sensitivity to measure trace gases and can at best detect parts per million concentrations. CRDS uses at three-mirror cavity and a tunable, single-frequency diode laser to create a continuous laser wave.

By measuring the amount of time it takes for the light intensity generated by this wave to decay, or "ring down," the technology can automatically and continuously detect gases in the air.

Differentiates methane sources

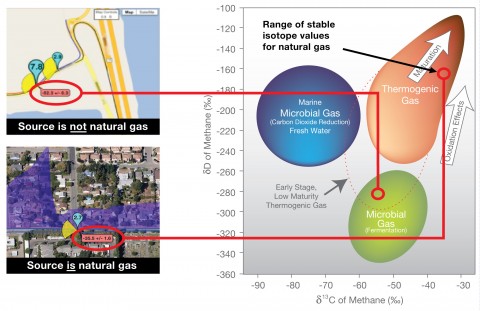

This specific implementation of a three-mirror cavity increases the path length of the continuous wave to several kilometers. Additionally, by tuning the laser to different wavelengths where a target gas absorbs light and mapping the various points, the technology is able to determine the precise concentration of gases. CRDS is able to detect gases at the parts per billion. More importantly, by accounting for the range of stable isotope values for a given gas, Picarro’s CRDS is able to distinguish between different forms of the same gas, such as thermogenic methane and microbial methane.

CRDS can distinguish a range of isotope values for natural gas

Uniquely mobile, Picarro Surveyor for Natural Gas Leaks mounts CRDS instruments, which are one thousand times more sensitive than standard leak detection equipment, in the trunk of a vehicle. It radically simplifies leak detection by integrating wind transport physics into its leak detection analytics to instantly identify leak locations. P-Cubed, which powers its data analysis, mapping, archive and reporting features, provides graphical visualizations of the surveyed area for simultaneous viewing by numerous users on an iPad or other web-enabled devices. All combined, these capabilities enable operators to conduct leak surveys while driving at normal traffic speeds, find previously undetectable leaks, and dramatically improve leak survey productivity and regulatory compliance.

From a mobile tablet or other web-enabled device, users can conduct a survey; view results in real-time; locate emission and leak source.

Cutting-edge science for detecting trace gas packaged in a mobile platform and delivered through a familiar, web interface, radically simplifies the science of gas measurement and helps organizations proactively capture fugitive emissions, modernize aging infrastructure, improve efficiency, and protect the public and the environment.

Written by: Suresh Pisharody, Vice President of Marketing for Picarro, Inc.

Back to Features

Back to Features