Until recently, ultrasound and X-ray imaging systems were the only technologies that could look inside a product and detect impurities that are not visible from the outside. Ultrasound systems need a medium such as water between the measurement head and the device to feed the ultrasonic signal into the product, which makes them difficult to use. X-ray systems on the other hand, offer the possibility of non-contact inspection and high resolution, but X-rays have health risks related to the ionizing radiation. T-SENSE, developed by Hubner Photonics in cooperation with the Fraunhofer Institute for High Frequency Physics and Radar Techniques, is a terahertz-based system that is both non-contact and radiation-free, and it can see through nonconductive materials such as plastics, compounds, ceramics, paper and clothing.

The Deutsche Börse Group, a financial services company headquartered in Germany with locations throughout the world, is using T-SENSE to inspect mail. The T-SENSE unit is about the size of a printer and is used in mail rooms to inspect all mail (letters, envelopes and small packages) to ensure that there is nothing dangerous inside. In fast mode the system can scan up to 1000 letters/envelopes (DIN C4) in an hour. Objects smaller than 1mm can be visualized in high-resolution mode.

T-SENSE visualizes the invisible in mailroom application.

Users have found that the main advantages are safety, powder detection and ease of use. Safety comes from the fact that terahertz is much safer for the operator because there is no harmful radiation, so it can be operated in any mail room or office setting without safety precautions. It features a graphic user interface and an protocol (pdf file) that’s generated by the click of a button, making it very easy to use with no training. The protocol is meant for documenting suspicious mail scans and it contains date, time, user, the THz image and then a text field for additional comments. In some cases the users produce such a protocol if they are not sure about the content of a letter to send the protocol via email to the receiver, asking this is expected as incoming mail. More generally suspicious findings get documented with the protocol function and forwarded with the suspicious object as a PDF or printout to the security person in charge of taking care of further steps.

The way it works

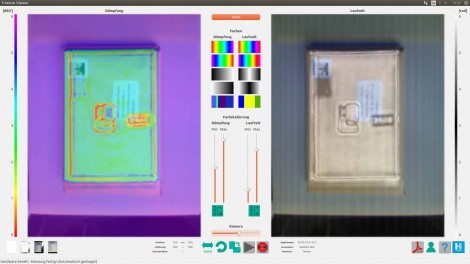

The T-SENSE scanning system consists of two rotary discs or turntables and a conveyor belt. The operator places postal items on the T-SENSE conveyor belt, and an integrated camera makes an image of the item. Then the item is scanned with electromagnetic waves in a low frequency terahertz range, penetrating the item and they are received by a detector on the lower turntable. The onward movement of the conveyor belt facilitates the quick production of a linear image. Each line of the image is portrayed in real time, and then a complete terahertz picture is produced. The user can pre-select filters and can color code specific threats. Upon completion of the examination, a log is automatically created and saved, so no paperwork is necessary. Signal processing is done on a fully integrated computer, which is controlled by a touchscreen monitor.

Overlay of camera picture and THz images for easy localization of hidden objects inside mail

In combination with Hubner Photonics’ T-COGNITION, a terahertz spectrometer identifies materials in the mail. T-COGNITION uses time-domain spectroscopy to conduct a point-by-point investigation of the sample without having to handle or open the item in question. Within seconds, by using broadband THz pulses (0.1 to 4 THz, usable range) it identifies the spectroscopic fingerprint of the hazardous substance or material by comparing the data with its own database. Results are color coded: green means nothing was found and red indicates that a substance was found, and it is identified.

Future advancements

While T-SENSE has been enhancing mail room security since 2014, new technical developments could make the system even better. Adding image recognition algorithms including artificial intelligence and machine learning could support the operator in their decision making. And, although the system is already about the size of a printer and able to sit on a counter or be carried from place to place, further size reduction may be possibly by using reflection geometry. Finally, there is the potential to extend the T-SENSE concept to a THz-time-domain spectrometer for fast broadband imaging with frequencies from approx. 0.1-2 THz for non-destructive testing applications such as inspecting food inside of packaging, inspection of flat plastics to detect flaws or extrusion of rubber and plastics to prove homogeneity during production.

T-SENSE is used in corporate mail rooms, prisons, law offices and other places where items in the mail may be a threat to safety. Overall, the terahertz imaging system offers insurance against dangers, reduction of expensive false alarms and protection of staff with ease of use and no risk to health.

Written by Anne Fischer, Editorial Director, Novus Light Technologies Today

Back to Enlightening Applications

Back to Enlightening Applications