Lasers have become so ubiquitous in today's world that it’s hard to imagine that the first one was built less than 60 years ago. Laser, which is an acronym for “light amplification by stimulated emission of radiation,” is a technology commonly used in our everyday lives. Lasers are in the optical drives in computers, in barcode readers in the grocery store, in aesthetic and dental treatments, in surgical procedures, manufacturing and more. While the science of light itself has not changed, laser technology has advanced rapidly and today we have a myriad of laser types that wouldn’t have been thought possible 60 years ago. Some of the latest advances include the all-silicon laser, a holmium doped laser on a silicon photonics platform and a flying microlaser.

The all-silicon laser

Researchers at Fudan University in Shanghai, China, developed an all-silicon laser, using silicon nanocrystals with high optical gains. Lead researcher Xiang Wu call his team’s all-silicon laser the “the last piece missing from the jigsaw of silicon photonics.” He sees this step as leading to a new revolution in information technology, “…

![]() similar to the case of integrated circuits and electronics happening, decades ago.”

similar to the case of integrated circuits and electronics happening, decades ago.”

The bottleneck that had prevented the realization of all-silicon lasers until now is the low optical gain of silicon nanomaterials, such as nanocrystals. The researchers developed a way of improving the density of silicon nanocrystals in the gain layer to enhance the light intensity. Then they used a unique approach of high-pressure surface passivation t the gain layer, resulting in the boosted optical gain of silicon nanocrystals becoming comparable to that of commonly used III-V lasing compounds.

The biggest challenge in developing the all-silicon laser, according to the professor, was to figure out how to increase the optical gain of silicon nanocrystals to a level comparable to that of commonly used III-V lasing compounds

The applications of silicon lasers include data communication, lighting, imaging, display, bio and chemical sensing, etc.

For more information read All-Silicon Laser: The missing piece to the integrated silicon photonics jigsaw

Holmium-doped laser on silicon photonics platform

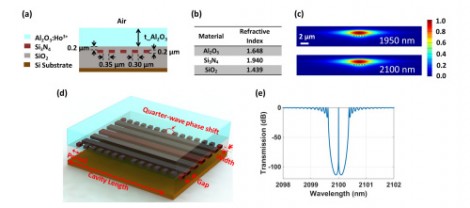

Mid-infrared laser sources have broad applications in communications, detection, medicine and sensing. Fabricating them on a silicon photonics platform brings down manufacturing costs because they can be made in a standard CMOS foundry. A team of researchers from the Massachusetts Institute of Technology (MIT), Harvard University and other institutions recently demonstrated a holmium-doped distributed feedback laser monolithically integrated on a silicon photonics platform. What is truly new and unique about this laser and had not been accomplished before is that it shows the lasing on silicon wafer beyond 2.0 µm wavelength.

(a) Cross-sectional view of the laser waveguide including five strips of Si3N4, an Al2O3:Ho3+ film, SiO2 and air as a lower and upper cladding, respectively on Si substrate. (b) Refractive indices of the waveguide materials. (c) Transverse-electric (TE) field intensity for the fundamental mode at the pump (1950 nm) and laser output (2100 nm) wavelengths in the DFB waveguide. (d) 3D illustration of the DFB laser showing the different material layers and cavity features (not to scale). (e) Calculated transmission of designed DFB cavity at 2100 nm.

The monolithical integration is achieved by a single-step wafer-scale deposition process. One of the biggest challenges with this approach is to find the proper holmium doping concentration for the laser. In the end, the team was successful in figuring out the doping concentration to give the best lasing power: Using a 1950 nm pump, they measured a maximum output power of 15 mW, a slope efficiency of 2.3% and a side-mode suppression ratio in excess of 50 dB. The next step in their research is to develop rare-earth doped lasers operating in the pulsed regime, based on this silicon photonics platform.

For more information read Monolithically Integrated Holmium Lasers

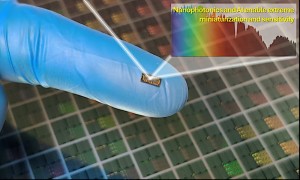

Flying microlaser

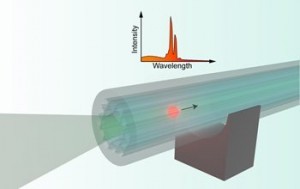

Imagine a tiny, flying laser that can move through optical fiber and deliver light inside the body. That’s exactly what researchers developed at the Max Planck Institute for the Science of Light. According to researcher Richard Zeltner. “By inserting a fiber into the skin, a microlaser emitting at a suitable wavelength could deliver precisely positioned light for use with light-activated drugs. The concept could also be applied in optofluidic lab-on-a-chip devices to provide a light source for various bioanalysis techniques or for on-chip temperature measurements with high spatial resolution.”

This is the first time that researchers have optically trapped and propelled a particle-based laser for centimeters inside an optical fiber. The new flying microlaser enables highly sensitive temperature measurements along the length of the fiber and could offer a novel way to precisely deliver light to remote and inaccessible locations. The flying microlaser is the first demonstration of distributed sensing using a whispering gallery mode resonator. This could be used for real-time continuous sensing along an optical fiber.

To test the new system’s ability to sense temperature changes, the researchers propelled the lasing microparticle along two regions of the fiber heated to 22 degrees Celsius above room temperature. By measuring shifts in the lasing wavelengths emitted from the microparticle, they could precisely detect changes in temperature as the microlaser moved through the fiber. The sensor detected temperature changes of just under 3 degrees Celsius and provided a spatial resolution of a few millimeters.

Using a technique called laser Doppler velocimetry, the researchers determined that the particle moved at a speed of 250 microns per second during the experiment. They say that using a fiber filled with air rather than water could increase the propulsion speed to centimeters or even meters per second.

Although the microparticles used in the experiment tend to lose their ability to lase after about a minute due to photobleaching, the researchers say that microparticles with different gain materials could solve this problem. They are also exploring whether multiple microlasers could be manipulated inside the fiber simultaneously and are working on improvements of the particle position detection scheme.

For more information, read Researchers Create Microlaser that Flies Along Hollow Optical Fiber

Back to Features

Back to Features