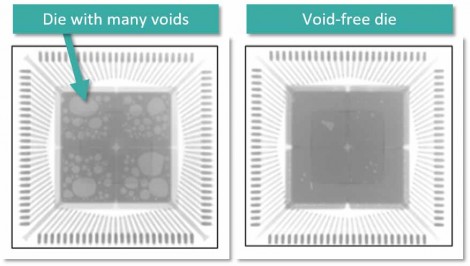

Void-free bonding is defined as voids in the bonding material interface, for example solder, that are equal to or less than 5% of the interface area.

Creating a void-free bond is critical in some applications because voids in the interface bond degrade product performance and reliability. The more demanding the application (either in terms of higher power or improved specifications), the greater the need for as little void as possible in the bond.

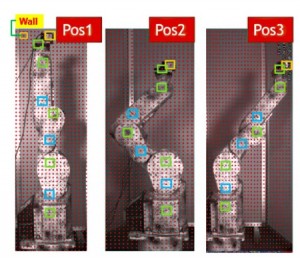

Figure 1: Example of a die with many voids and one with less than 5%, or void-free.

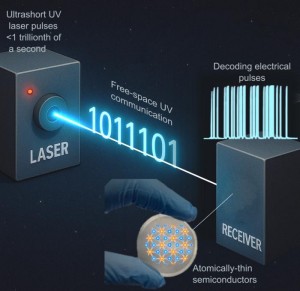

Void-free is critical wherever high-power, high-performance, high efficiency and long-life reliability are important. Some specific applications include devices for aerospace, defense, submarine, medical, high-power electronics, high-performance sensors in EVs, high-power transmission products lasers and LEDs. Even seemingly simply devices like HVAC systems or escalators require void-free solutions.

Systems, Tools, Processes Necessary for Void-free Die Attach

Using the correct system, tooling, process, and making wise material choices while considering material preparation are all factors and important points that need to be considered when looking to achieve void-free die attach.

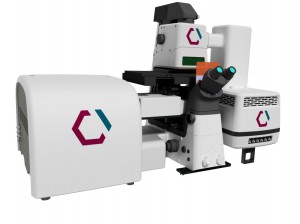

Vacuum reflow systems is one solution that can provide the perfect controlled environment by using optimum tooling design and tightly controlled parameters that control vacuum, heat, forming gases, formic acid and the most important parameter of all – overpressure.

To achieve successful void-free die attach, the devices are located within custom design tooling and placed within a vacuum reflow chamber. Once the chamber is sealed, the profile consisting of multiple stages, typically including vacuum, pressure, pre-heat and reflow temperature along with cool down is commenced. The objective is to remove air, particulates and moisture to create as inert an atmosphere as possible. Nitrogen purging is typically done to assist this process.

The reflow chamber contains heating elements that should be either graphite resistive heating elements to create a radiant heat and edge heating elements, also of graphite, to create a very stable and uniform temperature within the chamber.

Custom tooling is absolutely key to the success in achieving virtually void-free die attach using a vacuum reflow system. The purpose of the tooling is to fix or stabilize the position of the components to be assembled.

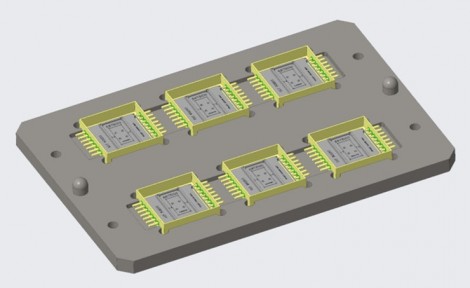

Figure 2: A graphite boat with six gold boxes filled with graphite tooling to stabilize a GaN RF component.

Figure 2 shows a fictious example of six butterfly packages in a “boat”. First, a custom graphite insert is placed in the package to align the substrate and subsequent following components. Next, the first preform solder is placed followed by the substrate. Now the semiconductor device needs to be located and fixed. To achieve this, an additional, secondary insert is placed to fix the die bond position within the substrate. A second 80Au/20Sn preform is placed. Once the preform is positioned the semiconductor device, in this example a GaN RF component, is placed.

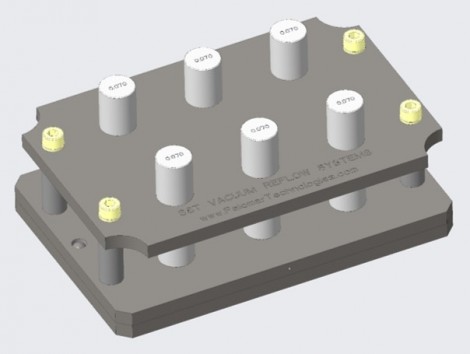

A “weight bezel” as seen in Figure 3 placed on top ensures the vacuum, temperature, and pressure work together to achieve virtually void-free die attach by enabling a downforce to be applied to the die, substrate and both layers of preform.

Figure 3: Final boat with tooling, weight bezel and weights.

Considerations for Successful Void-Free Attach

Selecting the correct solder can determine the success of the application. Before any other aspects of the solder can be determined, temperature limitations of the application must be specified. The melting point of the solder must fall within the limitations of the device components maximum temperature along with any other solders used.

Solder preforms are absolutely crucial to achieving void free soldering. Preforms can be cut to specific sizes and shape, depending on the application. Solder preforms do not contain any organics or other compounds that can hinder the die attach soldering process.

Lastly, flux should be avoided when selecting solder for a die attach application because flux can cause process issues and also mechanical equipment issues with flux getting caught in gas lines.

When executing a successful void-free soldering application, tight temperature control is extremely important. Large temperature fluctuations during the reflow stage of a soldering process can contribute to insufficient solder wetting, solder splatter, and overall increase in voiding.

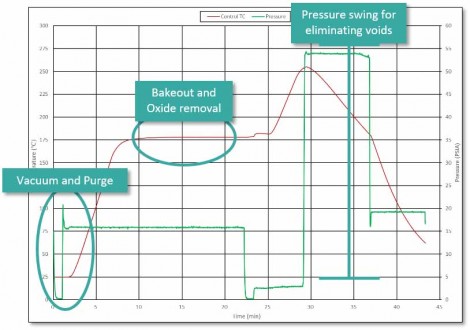

Figure 4 shows a look at a typical reflow system die attach profile.

Figure 4: Typical reflow system profile for an SST Vacuum Reflow System.

Using the ability to vary pressure within SST's vacuum reflow equipment, the first step removes oxygen or moisture in the chamber. The bakeout and oxide removal allows for continued moisture removal at an elevated temperature. At this moment in the profile, an oxide removal agent (e.g. formic acid) can be introduced into the chamber. Lastly, the pressure is aggressively increased while the solder is still in a liquidus state to ensure that maximum void elimination occurs. Having this capability available is a must for when void free die attach soldering is desired.

Tooling Considerations – Graphite is the Best

Tooling or fixtures hold solder and dies in place when conducting die attach soldering. Graphite tooling offers characteristics that other materials cannot e.g. low thermal expansion.Thermal expansion goes hand in hand in soldering applications.Typically, different materials are being soldered together and naturally, there will be competing thermal expansion coefficients; this is why graphite makes for a good option with its low expansion rate.

Additionally, graphite can withstand most, if not all, die attach soldering applications. It is not degraded through thermal cycling as long as it is used in an inert environment. Benefits of graphite:

- Excellent thermal conductivity and low thermal expansion

- Withstands high temperature (up to 2000C) while increasing strength

- Great for high current densities and aggressive ramp up times

- Low vapor pressure and is not degraded by thermal cycling

- Lightweight and easily machined

Solder interface and other factors to consider

There are many factors to consider when it comes to achieving successful die attach; one of the most important of these factors is solder interface voiding. Voids in the solder interface contribute to various failure modes including overheating via non-uniform dissipation of heat and high mechanical stresses. Using the proper material, solder and process/tooling is critical to achieving low-void.

Vacuum reflow systems offer solutions to achieve low solder interface voiding through chamber pressure manipulations and surface treatment options. In addition, the correct solder material selection is key in achieving excellent bond quality. Each application is unique and requires careful consideration when it comes to solder material selection.

Written by Gonzalo Esparza, David Taylor, Martyn Davies, Palomar Technologies

Back to Features

Back to Features