The Hong Kong Polytechnic University (PolyU) recently developed an intelligent fabric defect detection system, called “WiseEye,” which leverages advanced technologies including artificial Intelligence (AI) and Deep Learning in the process of quality control (QC) in textile industry. The system effectively minimizes the chance of producing substandard fabric by 90%, thus substantially reducing loss and wastage in the production. It helps to save manpower and to enhance the automation management in the textile manufacturing.

Supported by AI-based machine-vision technology, “WiseEye” can be installed in a weaving machine to help fabric manufacturers to detect defects instantly in the production process. Through the automatic inspection system, the production line manager can detect the defects, thus helping them to identify the cause of the problems and fix them immediately.

“WiseEye” is developed by the Textile and Apparel Artificial Intelligence (TAAI) Research Team, which is spearheaded by Professor Calvin Wong, Cheng Yik Hung Professor in Fashion of Institute of Textiles and Clothing, PolyU.

Textile manufacturers currently rely on human efforts to randomly inspect the fabric by naked eyes. Due to human factors such as negligence or physical fatigue, defect detection by human labour is usually inconsistent and unreliable. Textile manufacturers also attempted to use some other fabric inspection systems, but those systems were not able to meet the industry needs.

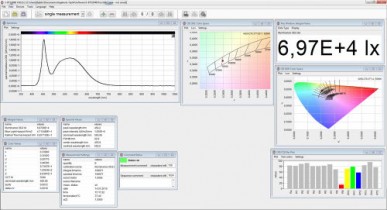

Wong says: “ ‘Wise Eye’ is a unique AI-based inspection system that satisfies the requirements of textile manufacturers. It is an integrated system with a number of components that perform different functions in the inspection process. The system is embedded with a high-power LED light bar and a high-resolution charge-coupled device camera which is driven by an electronic motor and is mounted on a rail to capture images of the whole width of woven fabric during the weaving process. The captured images are pre-processed and fed into the AI-based machine vision algorithm to detect fabric defects. Real-time information gathered throughout the detection process will be sent to the computer system, and analytical statistics and alert can be generated and displayed as and when needed.”

The research team has applied big-data and deep-learning technologies in “WiseEye.” By inputting data of thousands of yards of fabrics into the system, the team has trained “WiseEye” to detect about 40 common fabric defects with exceptionally high accuracy resolution of up to 0.1 mm/pixel.

“WiseEye” has been put on trial for over six months in a real-life manufacturing environment. Results show that the system is able to reduce 90% of the loss and wastage in fabric manufacturing process when compared with traditional human visual inspection. That means the system helps cut down production cost while enhancing production efficiency at the same time.

At the moment, “WiseEye” can be applied to most types of fabrics with different weaving structures and solid colors. The research team plans to further train and extend the system to detect defects in fabrics with more challenging patterns, such as complicated strip and check patterns. The ultimate target is to cover all common kinds of fabric in five years’ time.

Wong and the TAAI research team have been conducting fundamental and applied research on AI, computer vision and machine learning, specifically for the fashion and textile industry since 2012. The team has earlier introduced the first-of-its-kind “FashionAI Dataset” which integrates fashion and machine learning for systematic analysis of fashion images through the use of AI. The Dataset helps advance the fashion industry and develop a new mode for fashion retail.

Back to News

Back to News