Fiber optic technology was introduced more than 35 years ago and has become the most cost-effective cabling solution for reliable, long distance, high-speed data transfer with the greatest data densities. Our continued and growing dependence on the internet and the streaming of video into our homes is a sure sign we’ll continue to see improvements to fiber optic cabling, connectors and optical engines in both cost and performance for many years to come.

One of the drivers to adopt fiber is the need to transfer the data now easily available from high speed CMOS sensors and the need for improved vision inspections at ever-faster rates.

The machine vision industry – which has traditionally relied on copper cable solutions – is moving toward fiber and taking advantage of its many benefits, including:

- Low cost - $40 for 10m adding $0.5 per meter beyond

- High bandwidth - up to 1.2 Gbps in a single cable today and increasing

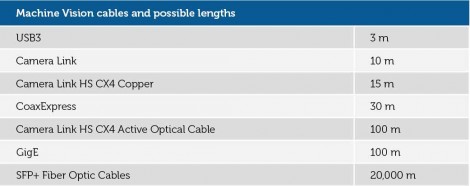

- Long distance – from 300 to 20,000 m, depending on transceiver module

- Immunity to radiated emissions – robust data transfer near heavy machinery

- Small size with tight-bend radius – easy to route

- Light weight, high flex-life cables – long lasting, easy to move

Fiber has very low attenuation loss over long distances compared to copper cabling.

About cost

In the past, fiber optic cabling was cost prohibitive for machine vision, but today the cost difference between short-distance Small Form-Factor Pluggable (SFP+) 10 Gbps copper and optical cable is shrinking and will only continue to do so.

- A passive 7-meter copper cable costs about $42 – about the same as fiber. For longer distances, fiber is, in fact, less expensive.

- A 30 meter distance in copper is not possible without repeaters (i.e., more $$). A fiber solution costs roughly $52 (in fact, shipping may cost more than the cable)

Today, imaging components using SFP+ fiber using CLHS protocol are available from several manufacturers, including KAYA Instruments, PCO Imaging, Silicon Software, and Teledyne Dalsa.

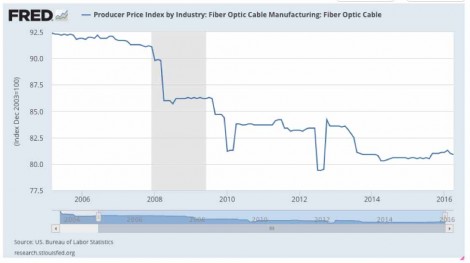

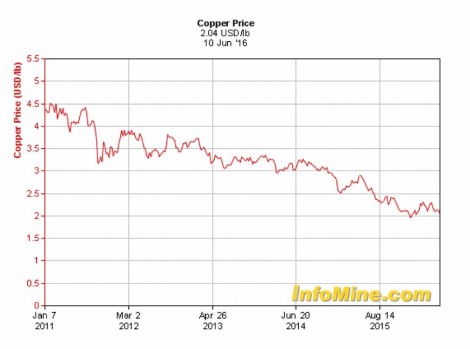

Conventional cable systems use large amounts of copper, and while commodity prices have been steadily falling for the last several years, copper prices are still vulnerable to exploitation and their boom and bust cycles. Meanwhile, the cost for fiber cable, components, and hardware has steadily decreased. Copper has an advantage in price over short distances of a few meters, but a fiber solution is less costly for longer runs.

Need more bandwidth?

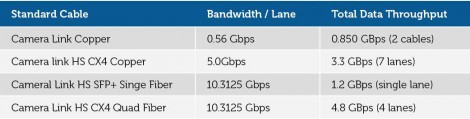

For those machine vision applications requiring even more bandwidth, plans are underway to include a multi-lane 10 Gbps connector solution to enable decreased camera/frame grabber sizes with higher bandwidths. The CLHS committee has proposed the CX4 connector to the Japan Industrial Imaging Association (JIIA) as a potential optical connector. The CX4 connector provides 7 down lanes and 1 up lane and is proven to operate up to 5 Gbps/lane, which enables 3.3 GByte/sec of effective data transfer in a single cable. The roadmap for this connector calls for 10 Gbps/lane and 16 Gbps/lane providing 8.4- and 13.4 GBytes/sec of data throughput respectively, in a single cable. Alysium has developed a thumbscrew Active Optical Cable (AOC) for this connector targeting 30 meter distances. Products with this connector are available from Teledyne Dalsa and Matrox. Many cable vendors offer CX4 copper cables today enabling customers to take advantage of the benefits of either copper or fiber cable solutions.

Other camera interfaces, such as USB3 Vision, also introduced AOC cables to benefit from fiber optic advantages, especially the longer cable length. And for many years, Camera Link has seen converter boxes using fiber optic cables to extend its 10 meter reach. Fiber optic is poised to become mainstream in many machine vision applications.

New paradigm for machine vision

Low-cost, high-bandwidth, long-distance cabling is a new paradigm for machine vision integrators. Fiber optic cable delivers that promise.

The machine vision industry can leverage the same benefits from fiber optic that the telecom industry derives. With optical connectors, such as those leveraged by the CLHS standard, fiber cabling is a realistic and effective solution. Our prediction is that fiber will become the transfer media of choice for machine vision very soon.

Written by Mike Miethig, R&D Camera Development Manager at Teledyne Dalsa (Waterloo, Ontario, Canada) and is Chair of the AIA’s Camera Link HS committee.

Back to Features

Back to Features