Advances in laser technology have had a tremendous impact on the medical industry, especially medical devices, which have allowed us to live longer, healthier, and happier lives.

Various wavelengths of light can be used in different ways in medical procedures. Selective laser trabeculoplasty is a procedure where a pulsed Nd:YAG laser can be used to ablate unwanted tissue inside of the eye suffering from glaucoma. Other applications such as skin surface treatments, including procedures to remove or diminish the effects of acne scars, sun damage, wrinkles, and even tattoos, are accomplished with first and second harmonic Nd:YAG lasers, CO2, Ruby, Dye, and Alexandrite lasers operating at visible, Near-IR, and Far-IR wavelengths. Holmium:YAG lasers and Argon lasers, operating at wavelengths easily absorbed by water, are used for surgical procedures such as phototherapy, soft tissue and stone removal. And the soft tissue eye surgery many of us are familiar with, such as the Lasik procedure, is achieved with the application of either Er:YAG and CO2lasers operating in mid and far-IR wavelengths. The full list of medical procedures involving lasers is longer and growing every day.

Lasers in medical device production

When discussing the development and production of medical devices, the importance of high power industrial lasers cannot be overlooked.

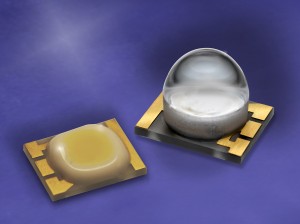

Lasers in the wavelength range from 980-1100nm, such as the Nd:YAG laser, disk laser, and fiber laser, are primarily used in medical device manufacturing for cutting, welding, and marking.

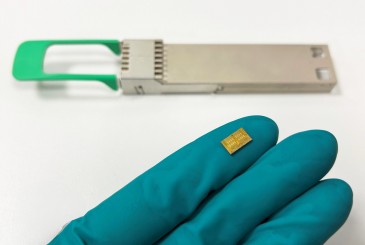

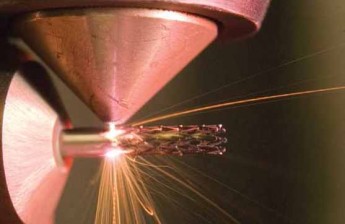

An angioplasty procedure involves the use of an expanded device called a stent that increases blood flow to the heart by removing blockages caused by blood clots or fat and calcium deposits. The stent, which is typically 2-4mm in diameter, is mass produced by taking a tube of the selected material, rotating that tube, and applying a highly focused laser to cut the design out of the tube.

Another medical device that uses a laser during production is the pacemaker. The pacemaker supplies low-energy pulses to a heart that is suffering from an arrhythmia and, therefore, beating at an abnormal pace. Since pacemakers are typically implanted into the patient, the case containing the electronics must be hermetically sealed by welding the two halves together. This weld is achieved by using a pulsed laser.

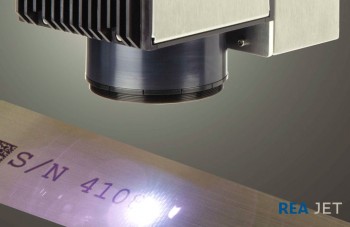

One application of the marking laser with respect to medical device is its use in traceability. Laser marking systems can apply an annealed mark to many metals to produce a dark coloration that can be easily read by the human eye for years. These dark marks can also be used to produce machine-readable codes, such as a 2D data matrix code. The benefit of the annealing process is that it does not ablate the material being marked. Ablation would subject it to bacteria collection, making it unacceptable for implantable devices.

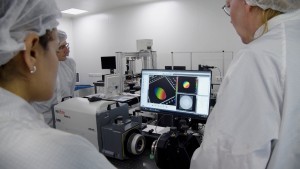

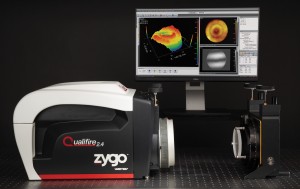

Controlling laser processes

Regardless of the application of the laser, whether for a medical procedure or production of a medical device, controlling the process is crucial. What all of these laser applications have in common is the amount of laser fluence (power density) that is applied to the material being processed. The measurement of two key laser parameters are needed in order to determine this fluence: laser power or energy, and laser beam size. Understanding how the laser performs, through periodic power or energy measurements and through the imaging and measuring of the laser beam size, is not only paramount to a successful laser process, it is required in some cases, such as in the production of implantable devices.

Over time, laser components can degrade and become damaged, or misalign, which reduces the overall efficiency of the laser system.

This may cause a reduction of the laser output power or cause variations in the beam size, which usually results in a decline of the fluence being applied to the material. Only through measurement of laser parameters that are key to a laser process can one fully ensure that the long-term quality of the process is maintained.

With advances in laser technology, the number of different applications seems to grow exponentially. And there doesn’t seem to be any limit to where this technology can go. Helping understand how the laser behaves is why the measurement of the laser system is vital to the success of the system where that laser is applied.

Written by John McCauley Product Specialist for Ophir-Spiricon’s line of laser measurement systems.

Back to Features

Back to Features