Hyperspectral systems acquire data in a set of narrow spectral bands which are then combined to form a three-dimensional (3D) datacube that comprises two spatial dimensions and one spectral dimension of a scene. Such datasets can be acquired in a number of different ways – either through the use of spatial line scan systems, spectral scanning systems or by using a single snapshot technique. In all cases, however, optical elements or mechanical devices need to be deployed in the hyperspectral instrument to separate the spectral bands of light before it is focused onto the detector array.

Now, in an attempt to reduce the cost of hyperspectral systems, researchers at the Belgium imec microelectronics institute have developed custom sensors that eliminate the need for such optical elements or mechanical devices. To do so, they have taken standard CMOS sensors and built a series of Fabry-Pérot interferometric filters onto them which enable the devices to acquire multiple spatial bands in parallel with each spectral band.

More precisely, three different types of sensor have been built at imec – a line scan sensor, a snapshot mosaic sensor and a snapshot tiled sensor (Figure 1).

Three different types of hyperspectral imaging sensor have been built at imec – a line scan sensor, a snapshot mosaic sensor and a snapshot tiled sensor.

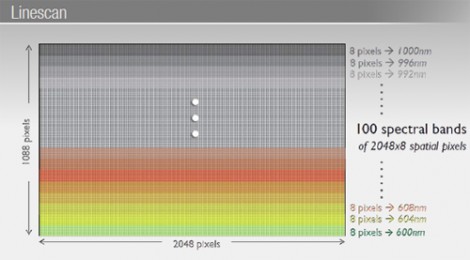

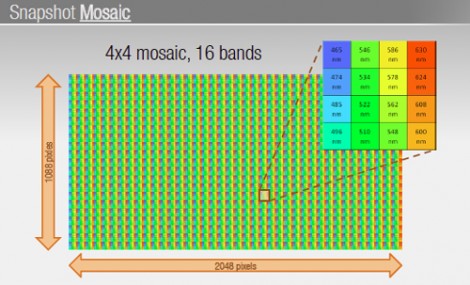

The line scan sensor is a 2028 x 1088 device divided into 100 spectral bands of 2048 x 8 pixels that capture the near infra red range of the spectrum from 600nm to 1000nm. The snapshot mosaic sensor differs from the line scan sensor in that a 4 x 4 mosaic filter is deposited at regular intervals across the pixels in the device, similar to the way in which a Bayer filter mosaic is deployed in a RGB camera. The 4 x 4 mosaic filter enables the 2028 x 1088 pixel device to simultaneously capture visible light in 16 spectral signatures ranging from 465-600nm. The third of the imec sensors -- the snapshot tiled sensor -- uses thirty two 256 pixel x 256 pixel tiles placed across the sensor that filter light into 32 bands from 600nm to 792 nanometers. With this design, an external optical duplicator would be required to duplicate any acquired image across each of the tiles to simultaneously capture a three dimensional datacube.

Compact hyperspectral imaging

The advantage of using such devices in a hyperspectral camera is that external optical or mechanical filtering once needed to separate out the different wavelengths are no longer necessary, since the filtering is performed on the devices. The result is that the bulky systems prevalent in today’s hyperspectral cameras can be replaced with just a lens and one of the integrated hyperspectral image sensors. Hence, hyperspectral cameras built using such devices can now be made as compact as a commercial machine vision camera and should be lower in cost than their contemporary counterparts.

That fact has not gone unnoticed at camera maker XIMEA, which announced in June this year that it had produced a range of cameras by integrating imec’s hyperspectral imaging sensors into its xiQ USB3.0 camera product line (Figure 2). Aside from their obvious hyperspectral imaging capabilities, the new cameras are small, light and low in power consumption -- with dimensions of just 26.4 x 26.4 x 21.6 mm, a weight of 27 grams and a power consumption of 1.8W. Due to the three different sensors that can be fitted to the camera, it is likely that each configuration will find its own specific niche in the market.

XIMEA has produced a range of cameras by integrating imec’s hyperspectral imaging sensors into its xiQ USB3.0 product line.

Cameras fitted with the line scan sensor, for example, may find a home in traditional industrial inspection systems, where they will be able to capture hyperspectral images of produce in the near infra red, enabling the water content to be determined. The snapshot mosaic sensor, on the other hand, appears to be a perfect fit for system integrators who want to integrate compact hyperspectral imaging cameras to drones and UAVs to capture hyperspectral images in the visible range. Due to the need for external optics, the snapshot tiled sensor may be adopted by medical imaging manufacturers where hyperspectral images captured by the camera could be analyzed to provide diagnostic information about the physiology, morphology, and composition of human tissue.

One of the early adopters of the new XIMEA camera has been Dr. Yosef Akhtman, a researcher at EPFL’s Geodetic Engineering Laboratory, and the founder and president of Swiss-based startup VISNX. He says that because of its size and functionality, the XIMEA camera fitted with the snapshot mosaic sensor can easily be fitted to small light aircraft or UAVs. The data collected from the camera can then provide researchers with a wealth of information about the composition of water and land, enabling them to characterize the changing nature of the environment in many regions on the Earth.

Flying ultralights over the delta

Working with a team of PhD students at EPFL, Akhtman has already built a remote sensing platform that was fitted to an ultralight aircraft to capture images around the delta of the river Selenga on Lake Baikal, a freshwater lake in the south of Siberia in Russia (photo above). The imaging platform uses the XIMEA hyperspectral camera fitted with the snapshot mosaic sensor, as well as a near infrared camera and a high-resolution RGB camera for photoreference purposes. This year, in over 100 hours of flights, the remote sensing platform imaged about 2000 square kilometers around the delta. In the coming year, Akhtman and his team will analyze the data collected by the system to determine the levels of pollution there.

Aside from its value determining levels of pollution, Dr. Akhtman says that another important application area for the new remote sensing platform will be in precision farming, where images captured by compact systems fitted to UAVs will be analyzed to diagnose the conditions of plants based on their spectral reflectance properties. The advantages of flying UAVs fitted with such systems as low as 100 feet above the ground will enable them to resolve features of plants down to less than an inch.

VISNX is working with multiples academic collaborators in the US and Europe to explore a number of applications of the hyperspectral imaging technology in precision farming. The detection of a bacterial disease known as Fireblight that kills the shoots of apples and pears, giving the plant the appearance of having been scorched by fire is one notable example. Another is the potential deployment of a system to detect Soybean rust, which has spread from Asia to the US over the past ten years.

Looking ahead, Dr. Akhtman says that his company also has plans to work with the Swiss Space Center to develop small so-called Hyper-CubeSat systems that will capture hyperspectral images from space.

By Dave Wilson, Senior Editor, Novus Light Technologies Today

Back to Features

Back to Features