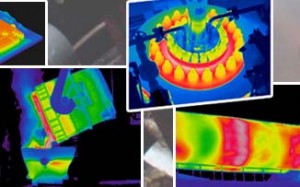

LumaSense Technologies introduced today a new infrared imaging technology called Rel-Rad or "relatively radiometric" imaging that bridges the gap between single-point pyrometry and thermal imaging to deliver precise thermal images at half the cost of fully radiometric systems.

Rel-Rad combines low-cost spot pyrometry with infrared thermal imaging technology to produce thermal images that are not fully radiometric but are "relatively radiometric." By driving the thermal image palette through a radiometric pyrometer capable of precise temperature readings, Rel-Rad delivers relatively radiometric infrared imaging at what the company reports can be at significantly lower cost than fully radiometric imagers.

Infrared cameras have proven to be the ideal non-contact temperature measurement technology in extremely hot manufacturing environments, but the high cost of imaging systems is often a barrier for many customers. LumaSense's new Rel-Rad technology is designed to make accurate thermal imaging more accessible, so operators can monitor an entire object or process instead of just a small portion.

Through its LumaSpec R/T software suite, LumaSense's Rel-Rad technology can be readily integrated with existing industrial monitoring and control systems via the Open Process Control (OPC) interoperability standard for industrial automation.

Rel-Rad is designed for industries where it's critical to know the temperature of an object as well as uniformity across an object at that temperature. Many processes in metals and glassmaking that use a single pyrometer to measure temperature can be improved with Rel-Rad technology, e.g., steelmaking processes like ladle preheat, torpedo car monitoring and annealing furnace operations. With the more precise temperature measurements that a Rel-Rad solution provides, the life of a pouring ladle or torpedo car can be extended by 20% and energy usage for preheat operations reduced by 10%.

Back to News

Back to News