Asbestos was once called a “miracle” material because of its toughness and fire-resistant properties. It was used as insulation, incorporated into cement and even woven into firemen’s protective clothing. Over time, however, scientists have pinned the cause of lung cancers such as mesothelioma on asbestos fibre inhalation. Asbestos was banned in the many industrialised countries in the 1980s but the threat lingers on in the ceilings, walls and floors of old buildings and homes. Now, a team of researchers from the University of Hertfordshire in the UK has developed and tested the first portable, real-time airborne asbestos detector. They hope that the prototype, described in a paper entitled “Real-time detection of airborne asbestos by light scattering from magnetically re-aligned fibers” that was published today in the Optical Society’s (OSA) open-access journal Optics Express will be commercialised in the UK in the next few years. It would provide roofers, plumbers, electricians and other workers in commercial and residential buildings with an affordable way to quickly identify if they have inadvertently disturbed asbestos fibres into the air.

Currently, the most common way to identify hazardous airborne asbestos at worksites is to filter the air, count the number of fibres that are caught and analyse the fibres with x-ray technology to determine if they are asbestos. The approach requires expensive lab work and hours of wait time. An alternative method to evaluate work site safety is to use a real-time fibre detector but the current commercially available detectors cannot distinguish between asbestos and other less dangerous fibres such as mineral wool, gypsum and glass. The University of Hertfordshire team’s new detection method, in contrast, can identify asbestos on-site. It does so by employing a laser-based technique that takes advantage of a unique magnetic property of the mineral.

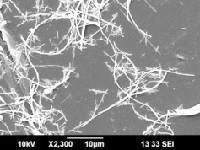

When exposed to a magnetic field, asbestos fibres orient themselves to align with the field. The property is virtually unique among fibrous materials. “Asbestos has a complex crystalline structure containing several metals including silicon, magnesium and iron. It is thought that it is the iron atoms that give rise to the magnetic properties but the exact mechanism is still somewhat unclear,” says Paul Kaye, a member of the team that developed the new detection method at the University of Hertfordshire’s School of Physics, Astronomy and Mathematics. Kaye notes that his team wasn’t the first to try to exploit the magnetic effect to develop an asbestos detector. “Pioneering US-based scientist Pedro Lilienfeld filed a patent on a related approach in 1988, but it seems it was not taken forward, possibly because of technical difficulties,” he says.

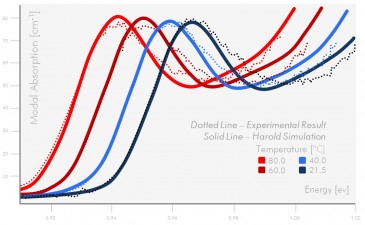

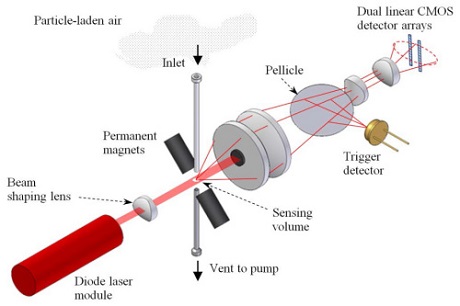

Schematic diagram of the Single-beam scattering system used to (a) differentiate fibres from non-fibre particles in the sample air and then (b) to measure the angle of orientation of the fibre particles relative to the airflow axis. The latter parameter can be used to indicate whether or not the fibres had been rotated during transit through the magnetic field, thereby indicating if they were asbestos. For clarity, the enclosure containing this optical assembly is not shown.

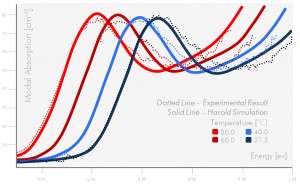

The Hertfordshire team’s new detection method, developed under the European Commission 7th Research Framework Programme (FP7) project ‘ALERT’ (FP7-SME-2008-2), works by first shining a laser beam at a stream of airborne particles. When light bounces off the particles, it scatters to form unique, complex patterns. The pattern “is a bit like a thumbprint for the particle,” says Kaye, sometimes making it possible to identify a particle’s shape, size, structure and orientation by looking at the scattered light. “We can use this technique of light scattering to detect single airborne fibres that are far too small to be seen with the naked eye,” he says. After identifying the fibres, the detector carries them in an airflow through a magnetic field, and uses light scattering again on the other side to tell if the fibres have aligned with the field. “If they have, they are highly likely to be asbestos,” Kaye says.

The team has tested their detector in the lab and has worked with colleagues in the UK and Spain to develop prototypes that are now undergoing field trials at various locations where asbestos removal operations are underway. “Our colleagues estimate that it will take 12 to 18 months to get the first production units for sale, with a target price of perhaps $700 to $800 USD,” Kaye says. As production increases after the initial product launch, Kaye hopes that costs may be cut even further, making the detectors even more affordable for an individual plumber, electrician or building renovator. “These trades people are the most frequently affected by asbestos-related diseases and most who get the diseases will die from them,” Kaye says. The team hopes that, over time, the new detector will help to reduce the 100,000 annual death toll that the World Health Organisation attributes to occupational exposure to airborne asbestos.

Back to News

Back to News