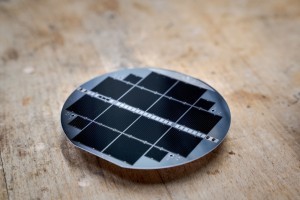

A central stage in the development of economic solutions for the industrial use of multi-junction solar cells for power generation has been reached. For the first time, an efficiency of 25.9 percent has been achieved with a multi-junction solar cell grown directly on a silicon substrate.

This record figure was achieved by researchers at the Fraunhofer Institute for Solar Energy Systems ISE in close cooperation with the Technical University of Ilmenau, the Philipps University of Marburg and the epitaxy experts at AIXTRON SE, a leading provider of deposition equipment for the semiconductor industry, as part of the funded "MehrSi" project. The team, together with scientists from the Fraunhofer ISE, succeeded in optimizing the layer structure and technology.

Key technology tandem photovoltaics

"For the first time we have now been able to realize a tandem solar cell based on a silicon wafer with such high efficiency," comments Dietmar Schmitz, Vice President Corporate Technology Transfer at AIXTRON SE. Until now, the production of III-V multi-junction solar cells has been based on a more expensive substrate material, for example also a compound semiconductor material.

Dietmar Schmitz emphasizes what is special about this basic research: "The gallium and phosphorus atoms must occupy the correct lattice positions at the interface with silicon. To achieve this, we have to control the atomic structure very well. This requires exceptionally high precision. In addition, to achieve the necessary high quality of the epi-wafers, it is crucial that a high crystal quality of all layers is achieved during epitaxial growth. This was achieved in the project thanks to the improved system technology developed by AIXTRON and the good cooperation with the project partners".

Low price - High cost attractiveness of silicon wafers

In this so-called tandem photovoltaics, different combinations of high-performance solar cell materials are arranged in layers on top of each other in order to use the different wavelengths of sunlight more efficiently when converting light into electrical energy. Silicon is suitable for absorbing the infrared portion of the sunlight spectrum. Layers of different III-V semiconductor compounds, a few micrometers thick, are then applied to the silicon base to convert the ultraviolet, visible and near-infrared light more efficiently into electricity. Tandem photovoltaics is a key technology for the energy transition. Due to the silicon used, the multi-junction solar cells grown on a silicon substrate are more cost-effective than solar cells based on other substrates.

Work on faster crystal growth to further reduce manufacturing costs

From the technological basis that has now been achieved, the alliance partners are working at high pressure to further increase efficiency and reduce manufacturing costs. To this end, the deposition of the layers is to be realized even faster, with higher throughput and thus more cost-optimized. In addition, the efficiency of the solar cells is to be further improved.

"Specifically, the dislocation density in the III-V solar cell layers is to be reduced from 108 cm-2 to the range of 1-5*106 cm-2 in order to increase the efficiencies to more than 30 percent. And last but not least, the cost-effectiveness of the epitaxy processes is to be further optimized," explains Prof. Dr. Michael Heuken, Vice President Corporate Research and Development at AIXTRON SE.

By means of more cost-effective processes in combination with silicon as the lowest sub-cell, tandem technology is to be made accessible for broad-based photovoltaics in the future. AIXTRON has already been working on such III-V multi-junction solar cells on silicon with several partners for many years.

The project "SiTaSol" for the joint development of layer packages that can be produced as quickly and cheaply as possible is funded by the EU. In "SiTaSol" AIXTRON has built and tested a specially optimized Metal Organic Chemical Vapor Phase Epitaxy (MOVPE) system in its own laboratory.

AIXTRON SE is a leading provider of deposition equipment to the semiconductor industry. The Company was founded in 1983 and is headquartered in Herzogenrath (near Aachen), Germany, with subsidiaries and sales offices in Asia, United States and in Europe. AIXTRON's technology solutions are used by a diverse range of customers worldwide to build advanced components for electronic and opto-electronic applications based on compound, silicon, or organic semiconductor materials. Such components are used in a broad range of innovative applications, technologies and industries. These include LED applications, display technologies, data storage, data transmission, energy management and conversion, communication, signaling and lighting as well as a range of other leading-edge technologies.

Back to News

Back to News