How to choose the appropriate camera sensor for specific military application is the topic of this three-part series. The first article, Camera Sensors for Military Use: Design fundamentals, covered the main variables to consider: Purpose, functionality and SWaP (size, weight and power) as well as performance parameters and tradeoffs. The second article, Camera Sensors for Military Use: Sensor technologies, explored the particular features and function of CCD, EMCCD and CMOS sensor and introduce the equation for Noise Equivalent Power (NEP) and Noise Equivalent Irradiance (NEI). In this third and final article in the series, we look at how NEI is used to evaluate the sensitivity of wildly different cameras and to rank them for a given exposure time and wavelength.

The NEI is a powerful way of comparing different cameras. Because the quantum efficiency is a function of wavelength and the dark current is a function of the exposure time, it is important to use the wavelength and exposure time of interest for the given application.

Silicon cameras

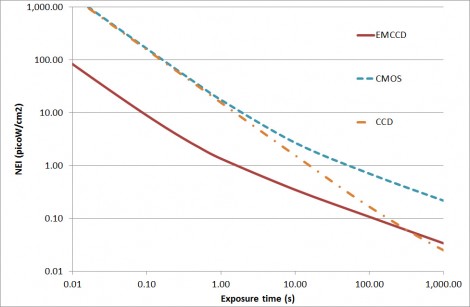

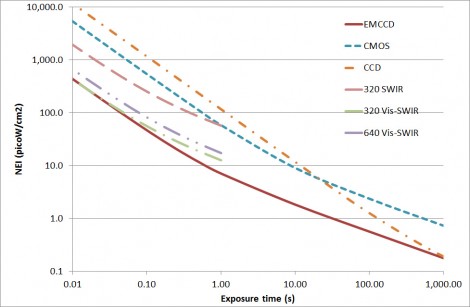

EMCCDs are best for short exposure times (milliseconds) while CCDs are best for long exposure (minutes). For exposure times in seconds, all technologies are in a similar order of magnitude. Still the NEI allows for a precise comparison and ranking.

|

|

EMCCD |

CMOS |

CCD |

|

QE |

47.3% |

51.5% |

78% |

|

Pixel size (µm) |

10 |

5.5 |

4.54 |

|

Full well capacity (e-) |

24,00 0 |

14,000 |

12,000 |

|

Readout noise (e-/p) |

<1 |

7 |

7 |

|

Dark current (e-/p/s) |

1 |

9 |

0.08 |

|

NEI (picoW/cm2) @ 33ms |

38 |

493 |

477 |

|

NEI (picoW/cm2) @ 10s |

1.6 |

2.7 |

1.6 |

|

NEI (picoW/cm2) @ 10min |

0.103 |

0.233 |

0.027 |

Silicon based detectors NEI at 550nm and Figure 1 compare the NEI of typical EMCCD, CMOS and CCD at 550nm for exposure times ranging from 10ms up to about 15min.

Figure 1: NEI of Silicon cameras at 550nm

InGaAs cameras

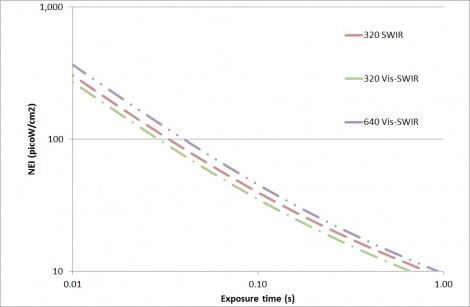

Below is a comparison of InGaAs FPA detectors NEI at 1550nm (in Table 3 and Figure 2). Because the readout noise and dark current is very large compared to silicon based detectors and are not compensated by the high QE and large pixel size. Long exposure times are also prohibited by the large dark current that fills up the full well capacity about one second. Notice how close all three cameras are despite the fact that the 640 Vis-SWIR has 4 times smaller pixels thanks to lower readout noise and dark current.

|

|

320 SWIR |

320 Vis-SWIR |

640 Vis-SWIR |

|

QE |

72.9% |

82.1% |

80% |

|

Pixel size (µm) |

30 |

30 |

15 |

|

Full well capacity (e-) |

170,000 |

170 ,000 |

12,000 |

|

Readout noise (e-/p) |

150 |

150 |

50 |

|

Dark current (e-/p/s) |

190,000 |

1 90,000 |

15,000 |

|

NEI (picoW/cm2) @ 33ms |

100 |

45 |

118 |

|

NEI (picoW/cm2) @ 0.5s |

13 |

11 |

14 |

Table 3: InGaAs FPA detectors NEI at 1550nm

Figure 2: NEI of InGaAs cameras at 1550nm

General comparison

We can compare cameras equipped with Silicon and InGaAs FPA detectors, using wavelengths where both technologies are sensitive. Figure 3 represents the NEI vs Exposure time at 950nm. Of course, this wavelength puts the silicon cameras at a disadvantage with much reduced quantum efficiency compared to InGaAs cameras. See Table 4 below

|

|

QE |

Pixel size (µm) |

Readout noise (e-) |

Dark current (e-/pixel/sec) |

|

EMCCD |

5.2% |

8 |

<1 |

1 |

|

CMOS |

8.9% |

5.5 |

7 |

9 |

|

CCD |

6.0% |

4.54 |

7 |

0.08 |

|

320 SWIR |

18.5% |

30 |

150 |

190,000 |

|

320 Vis-SWIR |

83.8% |

30 |

150 |

190,000 |

|

640 Vis-SWIR |

72.0% |

15 |

150 |

15,000 |

Table 4: Sensor specification at 950nm

Figure 3: NEI of Silicon and InGaAs cameras at 950nm

From Figure 3, in the NIR up to one second exposure time, EMCCD is the most sensitive technology, followed by Vis-SWIR and SWIR cameras, finally, CMOS and CCD differentiate mostly through the difference in QE between otherwise very similar specifications.

Noise Equivalent Irradiance allows us to precisely evaluate the sensitivity of wildly different cameras and to rank them for a given exposure time and wavelength. In the visible at short exposure time, EMCCD is the most sensitive technology followed by CCD and then CMOS. In the NIR InGaAs cameras have the edge over CMOS and CCD while in the SWIR, InGaAs is still the only existing possibility.

Allowing for trade-offs in sensor performance and choosing the optimum sensor for the application is only the beginning. Defining camera performance, functionality and building it to meet SWaP requirements then leads to designing a camera that drives the best performance from the sensor.

Written by Jean-Edouard Communal, Sales Manager at Raptor Photonics Ltd.

Read the full Camera Sensors for Military Use Series here:

Camera Sensors for Military Use: Design Fundamentals

Camera Sensors for Military Use: Sensor technologies

Camera Sensors for Military Use: Sensitivity comparison

Back to Features

Back to Features